Knowing how much to purchase involves a combination of forecast data analysis, company experience, and consumer awareness when it comes to inventory management. Even the most foresighted enterprises are likely to overproduce or overorder sometimes, leaving the business with unsold inventory, often known as deadstock.

Deadstock negatively influences sales and cash flow and accounts for important storage space; in some cases, it may even jeopardize a company's viability. Here is what is dead stock and the way to avoid accumulating dead stock and manage or reuse surplus inventory that currently exists in your warehouse.

Any unsold products that have been sitting in your warehouse or store for a long period of time are referred to as dead stock. Dead stock is harmful to any organization since it takes up too much space in your inventory. Besides, it also represents a poor investment. Stock that isn't selling indicates lost money because the money invested in purchasing the things from your vendor can only be repaid when they are sold.

👉 Read More: What Is Kitting In Manufacturing: Process and Benefits

👉 Read More: What Does A Backorder Mean: Managing Tips and Solutions

Do not mistake "dead stock" with "deadstock," a phrase used by a certain group of customers like sneaker collectors. Dead stock is a term used to describe defunct lines of unworn shoes, as well as vintage apparel and material that are no longer appearing on the market but it still retains their original tags. Dead stock goods, unlike dead stock, frequently sell for a higher price. Dead stock, on the other hand, is frequent in trading companies.

Give this a look if you're continually dealing with dead stock but can't seem to find a way to avoid it.

Unsellable inventory is referred to as dead stock. If it ordered or produced too many things and then realized it didn't even sell as expected, a company may end up with dead stock. Damaged goods, improper shipments, leftover seasonal items, and outdated raw materials are all examples of dead stock. Food and medication, for example, can easily turn into dead stock since they must be destroyed after a certain period of time.

Nonetheless, the dead stock does not contain products returned by buyers. Since things aren't normally deemed unsellable immediately, when does stock become obsolete? It's usually a lengthy procedure. Firstly, things might be classified as slow-moving stock. If they go unsold for a long time, they become surplus inventory and are finally classified as dead stock. Any inventory not turning over after one year is labeled dead stock and then becomes a debt in accounting terms.

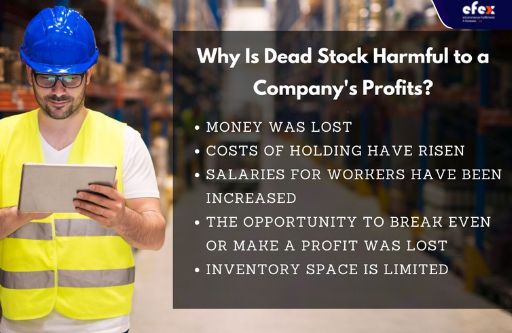

Because dead stock is costly, it is bad for the company. It locks up cash, reduces income, raises carrying costs, and consumes valuable storage or shelf space.

Dead stock, for example, can result in:

The main reason that dead stock is negative for the company is that it leads to money loss. Only when items are sold do companies recoup their inventory investments. That investment is wasted with dead stock.

These are the costs involved with holding goods, often known as stock carrying costs. Labor, storage space, and insurance are all common carrying expenses. The more money a business has locked up in inventory, the less money it has to spend on other things.

The more goods on the inventory, the more work it takes to keep track of everything. Dead stock can result in greater labor costs due to reshuffling, counting, and eventually disposal of products that will not generate income.

Even if you are able to sell the dead stock, it will almost certainly be at a deficit. Furthermore, the longer you keep handling unsold goods, the more money you spend on employees and the less chance you have to concentrate on profitable items.

👉 Read More: What is SKU Number? Example and Benefits

👉 Read More: What Is Stockout Cost? Formula And Example

Deadstock takes up significant shelf and storage space that could be used for items that sell more quickly.

The greatest visible expense of dead stock is revenue lost.

For instance, if a company can't sell 2,000 units of a commodity at $100 each, the company will possibly lose $200,000 in expected income. Other expenses may be large, but they are more difficult to estimate. Total carrying expenses can eat up to between 20% and 30% of a company's capital at a certain time.

However, it can be challenging to figure out how much of it is attributable to dead stock. Because the longer a product is kept before being sold, the greater its carrying costs can rise, the dead stock may be the worst-case situation for carrying costs. There may be an additional cost associated with dead stock since it monopolizes storage space.

Dead inventory consumes resources that may be used to invest in a stock that generates higher earnings. Consider this: inventory normally accounts for 35 percent of a restaurant's costs, yet some restaurants squander up to 10% of the amount for food – a bag of wilting fruit is one of the dead stock examples.

While bad inventory management procedures frequently result in dead stock, it's vital to remember that any company can end up with shelves full of unsold products. It's not really easy to forecast demand trends, and unforeseen economic variables might have a negative impact on consumer purchasing.

Here are 7 typical causes of dead stock in businesses with the solutions.

Forecasting isn't always accurate. Incorrect forecasting occurs when businesses mistakenly estimate demand and purchase too many goods caused by faulty data, unreasonable expectations, or causes beyond their control.

Companies can enhance forecasting performance by reviewing order history to gain a deeper understanding of demand, adding data on economic circumstances, and following rivals' activity, among other ways. Machine learning-based software for inventory management can aid forecasting by identifying trends in data.

A business may end up with excessive stock if it purchases products at an unsuitable time when demand is down or orders too many goods at once.

Regularly monitoring any of the 30-plus stock control KPIs that are important to the company will assist assure the business orders the correct quantity to refill stock at the right time. This can help prevent the problem of inconsistent purchasing.

Among the most important KPIs are:

For example, if the inventory turnover ratio equals 20, it will take you 18.25 days (365/20) on average to flip your inventory. This KPI will assist you in determining your future direction based on the previous year's statistics, as well as allow you to evaluate your ratio to the industry standard.

This tool will help you plan your next order to ensure not running out of stock or purchase too many things, which will increase your holding costs.

EOQ does exactly that: it advises you how many units you should purchase at once. It adds an extra layer of protection to the reorder point, lowering the risk of overstocking or dead stock.

It might be difficult to strike the appropriate balance between too few and too many goods offered. Having a wide range of items may appear to be a great approach to expanding your consumer base; however, the more SKUs you have, the more you have to handle – and sell.

Excessive SKU count is often unavoidable as a result of a company's expansion and the process of determining its consumer base. However, it is manageable. Assess your SKUs on a regular basis to identify which are high performers or underperformers. The earlier you can detect slow-moving products, the less money and bother you'll have to spend storing surplus inventory while reducing the risk of the SKU becoming dead stock.

A product may fail to sell for a variety of reasons. The price might be too expensive, it could be out of fashion, it could be less desirable than a competitor, or it could fail to meet the demands of the target market.

The first step is to figure out what's causing the low sales. You will need to improve your customer service, tweak your price, or change your inventory management tactics. Product bundling, big discounts, and online selling are all effective strategies.

Thus, if you have an item in your store that has been unsellable for a long period of time, you can combine it with a hot-selling item as a bundle or bonus offer. The purpose here is to remove slow-moving products before they become dead stock and eat into your profit margin.

Giving a discount will assist a business to attract a lot of customers who may have previously overlooked their products.

Because everyone with internet access can see your online shop, online platforms like eBay or shopping carts like Shopify help you to reach out to a wider audience. With a broad reach, you have a higher chance of turning dead stock into sales.

Even if your business has strong forecasting skills, shifting market conditions may cause unexpected declines in demand, leading to unsellable inventory

It's difficult to plan for events that are beyond your control. Maintaining effective inventory management techniques that avoid over-ordering and creating backup plans in case demand drops can help minimize the impact. The more agile your supply chain is, the faster you can adjust. To ensure to respond swiftly, several companies have made supply chain visibility (SCV) programs.

Customers are less likely to purchase things that are defective or substandard.

If your inventory isn't trading because of defective items, quality management standards will allow you to figure out what's wrong. You can eliminate this problem in the future by establishing strict criteria for raw materials and commodities before entering your warehouse and throughout manufacture.

Product specs, packing regulations, and AQL approaches may all assist you to make sure you're selling quality goods.

If a product fails to fulfill the specifications, it can be returned to the vendor for a replacement. The quality check requirement functions as a first line of protection, reducing the time required for future inspections.

You can specify requirements for items like the type of material, material quality, color, and compliance with certain government or third-party certifications.

To use an AQL, you check statistical samples of goods rather than the entire lot or batch and then approve or reject the entire lot depending on the sample's analysis. For instance, if your supplier has provided you with 100 pairs of shoes, you will evaluate 10 pairs for your AQL study. If your AQL is set to 4, that implies you will accept a batch of products if there are no more than four faulty items in that sample. It's a good idea to talk to your vendor about your product, packing, and AQL needs before signing a contract.

There's a significant risk you'll wind up with dead stock if buyers aren't interested in what you're selling.

Strong market research, which includes discussing with customers directly, may help you become more attuned to customer demands and requirements before investing in new products. If an established product isn't selling well and is on the verge of going out of stock, consider offering it at a discount.

- Read More: Order Management System: Definition, Process And Value

- Read More: Order management system for Ecommerce: Definition, Key Effect, Benefit

Dead stock is a problem with inventory management that doesn't get the proper attention. Carrying surplus stock that you can't sell may be bad for the company in a number of ways, and the effects can compound over time. The good news is that dead stock is easy to recognize. If you find yourself with extra inventory that you can't sell, the solutions outlined in this article will assist you to avoid repeating the problem.

In conclusion, inadequate inventory management is to blame for the majority of dead stock difficulties and understanding: what is dead stock. You'll have fewer worries about things languishing on your shelves if you utilize inventory management software as well as other tools that allow you to maintain your warehouse in order.