When a distribution facility reaches roughly 85% occupancy, it is theoretically out of space. However, If you run out of warehouse space, there are various options for you, such as increasing storage capacity without expanding the facility to optimize warehouse space. Let’s jump into this article to find the ways to do it straight away.

ESFR is a fire suppression sprinkler system typically installed in new buildings, and you can store inventory within 18 inches of that area. Rack extension has various drawbacks, including the possibility that the base plates or racking uprights are not adequately proportioned. In that situation, a professional engineer and a structural engineer will determine whether rack expansion is a possible alternative or not.

👉 Read More: 3PL Warehouse Services: Benefits And Offers

👉 Read More: All Cost To Rent A Warehouse In 2023

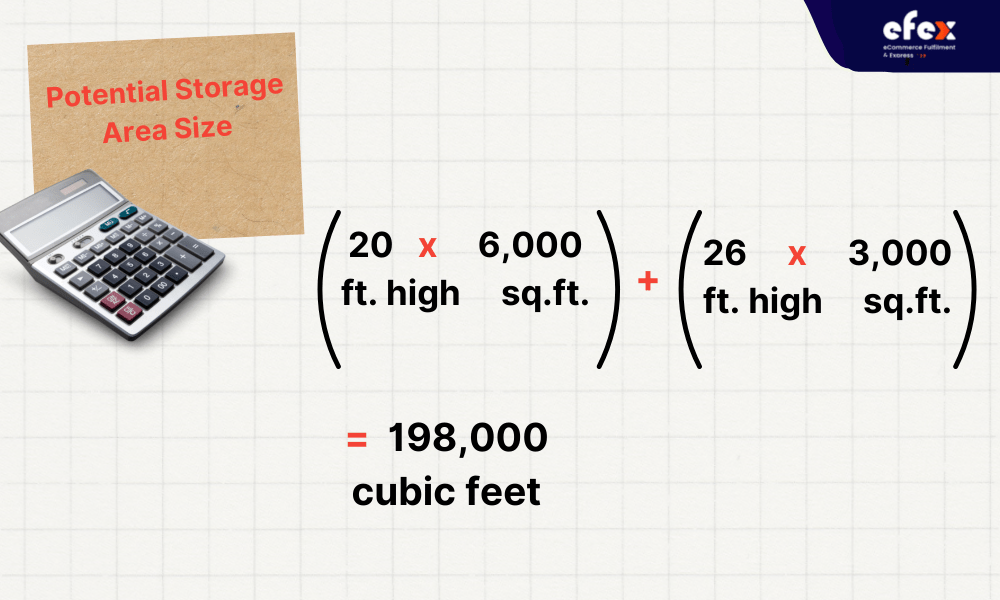

Constructing a mezzanine is one of the most effective methods to enhance your warehouse space. Having a mezzanine installed above the floor-level process, such as a shipping or receiving facility, can roughly quadruple floor space. However, some disadvantages come with installing a mezzanine. The floor load must be able to withstand it. Columns and foundation plates will fall to the floor. It is preferable to construct a mezzanine than enlarge the structure.

A standard wide aisle may be wide from 10 to 12 feet, but if it can be decreased to 5 - 8 feet, you can conserve about 15% - 20% of your warehouse area. You must assess lift equipment and consider whether it is designed to follow or function in those small aisles. You must also pay additional wire guiding charges in a particularly narrow aisle.

Another technique to maximize your warehouse space is to upgrade your warehouse to greater density equipment, such as switching from a single-deep rack to a double-deep rack. Loading pallets on a double-deep rack necessitates the use of a reach truck. Higher density equipment solutions include push-back or drive-in racks. These alternatives are excellent for expanding storage, but the difficulty is that they are FIFO (first in, first out). The higher density, the harder first-in pallets accessibility.

There are specific products that are only available in half-pallet quantities. Adding half-pallet locations can help save more space. You can imagine it like ice cubes in a glass. There would be more liquid if you pour water into it, and there would be more room in a glass if you put ice cubes in it. It is like fluid volume rather than just what is in that location. You can fit more pallets and more merchandise in the same space without sacrificing too much blank space when you compress your pallets.

This is also a wonderful technique to optimize warehouse space. Your warehouse managing system often directs it, so instead of placing the pallet anywhere you like, directed put-away understands which places are most suitable for pallets. It will direct you to place a certain pallet rather than allow a worker to place pallets in the most convenient area.

Pallet racks are full of supplies, slow-moving goods, or staging for inbound or outgoing cargo that has not been processed can typically be positioned above receiving or shipping doors. For instance, suppose a conveyor along the middle of the module and a pick module in the facility. You just need to hang a shelf above the conveyor. It helps you have more space to stock slower-moving or smaller goods that do not need to be refreshed regularly. Those items will have to be restocked manually or via the conveyor system.

Your warehouse may sometimes need temporary storage demands, so putting things on trailers is a solution you should not miss. Numerous warehouses will tend to bring in more trailers and pay the demurrage charge for temporary storage. It is popular for seasonal products, especially among merchants.

How to optimize warehouse space, you should concern with these two questions “How much of the area is being used?” and “What purpose is it used for?”. These usage data are critical in choosing the next measures to take. There are four simple methods for determining your current space utilization.

Forklift contact occurs in the area from the top of the stored product to the bottom of the rack beam. You just need to let 6 inches here, yet the load might be 8 inches and above away from the rack. Ways to make it right:

If it’s longer than 6 inches, consider the reason. What is occasionally placed here? The same size merchandise or a larger object?

Unpackaged parts are frequently housed in storage bins on shelves or racks. When saying about these containers, many warehouses likely use a “one size fits all” approach rather than having multiple sizes. Martin Murray from The Balance Small Business said: “ When the containers are stored on the rack, space maximization can appear to be good, but in reality, there is a lot of wasted space inside of the containers, which is costing the company money”. You can consult these solutions:

Simply keeping stuff in the appropriate size containers will help you discover more room that you have wasted and boost your warehouse capacity.

By dividing things according to size and keeping them among similar-sized items, you will maximize your free warehouse space. The procedure is identical to the preceding suggestion, and it is simpler than you would believe.

This method supports you create most of the space you currently own in your storage and reduces the possibility of misplacing smaller things because they are all together.

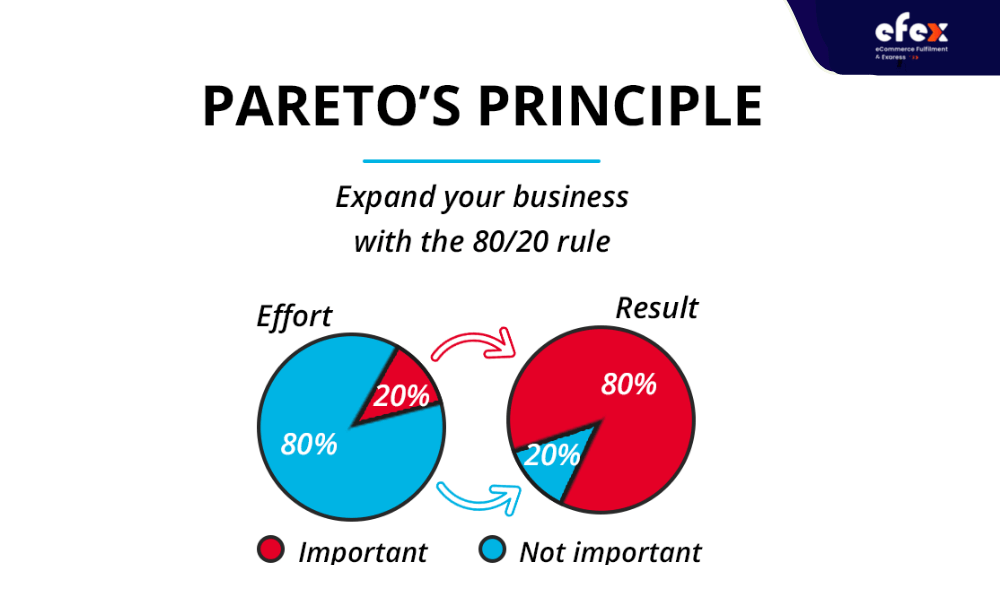

Pareto Principle, named after economist Vilfredo Pareto, states that 80% of the reason results in 80% of the consequences, implying an asymmetric connection between outputs and inputs. Pareto Principle can be applied in various industries, including business and warehouse storage.

In Victor Coronado’s paper on warehouse space optimization, he stated: “Eighty percent of the activity in a warehouse comes from 20 percent of the items, and these items are the fast-movers within the warehouse.” He applied the Pareto principle to describe a product analysis to choose the optimal SKU position.

Because the warehouse space is incredibly important, you should not take any outdated merchandise. The below steps will help you locate and eliminate the space invaders and maximize warehouse space:

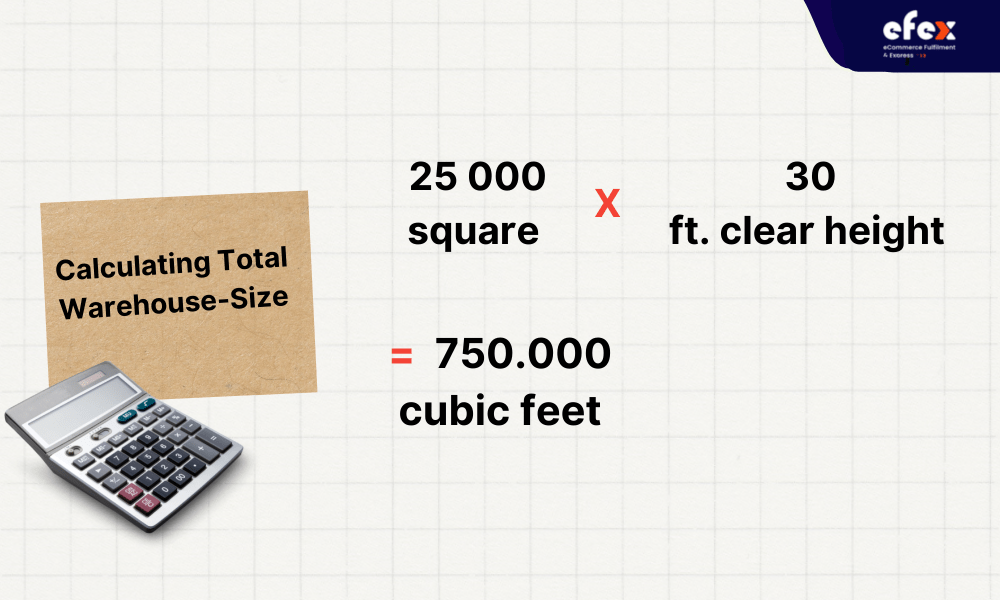

Improving your warehouse capacity by utilizing the vertical space in your storage that is currently accessible would be a tremendous help.

This way can help you reduce some amount of costs in the warehouse. Moreover, the added warehouse capacity frequently increases operating efficiency and productivity.

Reduce the aisles’ width between the rackings to increase accessible warehouse storage and provide some necessary square footage.

Optimizing your warehouse space by cleaning up your floor is a necessary way that you can not miss. Floor space is particularly significant because it is one of the most accessible areas in your storage, regardless of whether you utilize a floor stacking or a racking system.

>> Learn more: Floor stocking meaning and how it works in 2024

Another way to optimize warehouse space is by adding a mezzanine. Mezzanines allow you to increase useful square footage without really expanding.

Stocking too many same SKUs might overburden your storage. It happens more frequently than you expect. Someone in buying gets a terrific bargain on a six-month supply of certain goods, and your warehouse becomes overcrowded. This situation is readily correctable.

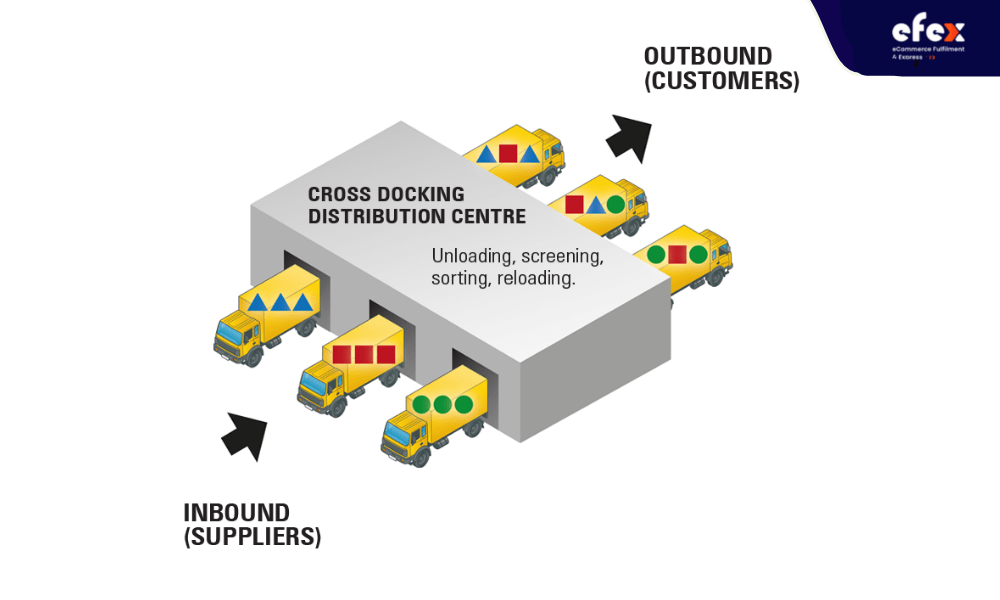

Cross-docking eliminates the need for merchandise to be kept between the legs of its route. It is instead immediately sorted and moved back to the distribution chain. The warehouse space optimization technique is tough to master, but it does save space.

Excess inventory can be caused by inaccurate forecasting, complicating storage inventory management. To increase your forecasting accuracy, you should consult these tips.

You can use inventory management software to create forecasts instead of a spreadsheet. Besides, you have to decide whether the scale of your facility and your projections call complexity for a different solution.

You should check the current predicted level regularly. For instance, forecasting at the SKU level would not be sufficient since forecasting by sales area or channel may require more detail.

Compare your projections to real sales. This data will help you fine-tune your forecasts and enhance your outcomes further.

The 5-S warehouse space optimization technique can assist you in enhancing warehouse space, minimizing waste, and boosting efficiency. You will recognize problems quickly, treat their root causes, and avoid recurring. The following are the fundamentals of adopting 5-S in your storage.

You should evaluate the usefulness of goods and eliminate any items that are no longer needed, like outmoded inventories or useless equipment.

There is one rule to follow, which is to put the best-selling items in the most visible places. Search for the underlying causes of each issue that arises. During the progressive, you may detect irregularity or a lack of structure in your storage. What you need is to make modifications and put countermeasures in place as you go. For instance, you may observe that stock is checked separately when it may be done in batches. Create policies or rules that you can repeat the process each time. It allows you to share the process with your group and welcome new workers.

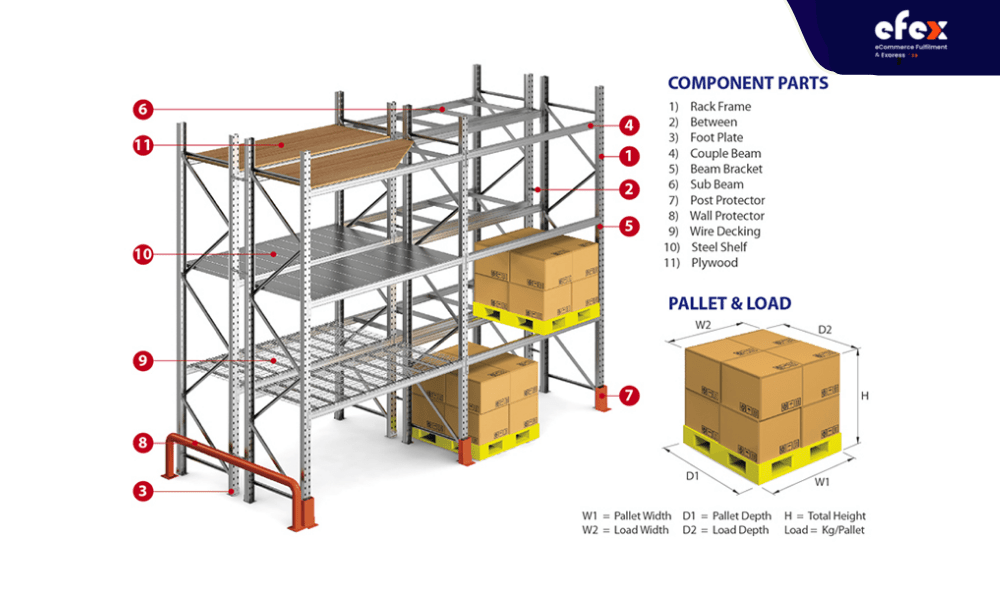

If you need higher storage, selective racking would not be your perfect storage method for your storage. Let’s consult the following ideas to optimize your warehouse space.

Now you should ask yourself these questions, such as do you require a lot of storage, or is it necessary for your warehouse system to support a first-in/first-out or last-in/first-out inventory management system, or does pick selectivity still an important factor to your warehouse?

Find out which storage method is finest for your storage and your top needs. You can take a glance at the most prevalent warehouse options below.

Pallets are placed in rows on the floor. This option allows you to have high-density storage if items or loads are piled directly on top of one other.

The depth of selective racking is one pallet. You can arrange racks in a row or against a wall. Despite the low storage density, this alternate solution will provide a high choice selectivity.

There are two rows of racking instead of back-to-back rows or one row. Racking can even be installed back to back and two rows deep. This technique helps you minimize the number of aisles while increasing storage density. However, this system requires a specialized forklift.

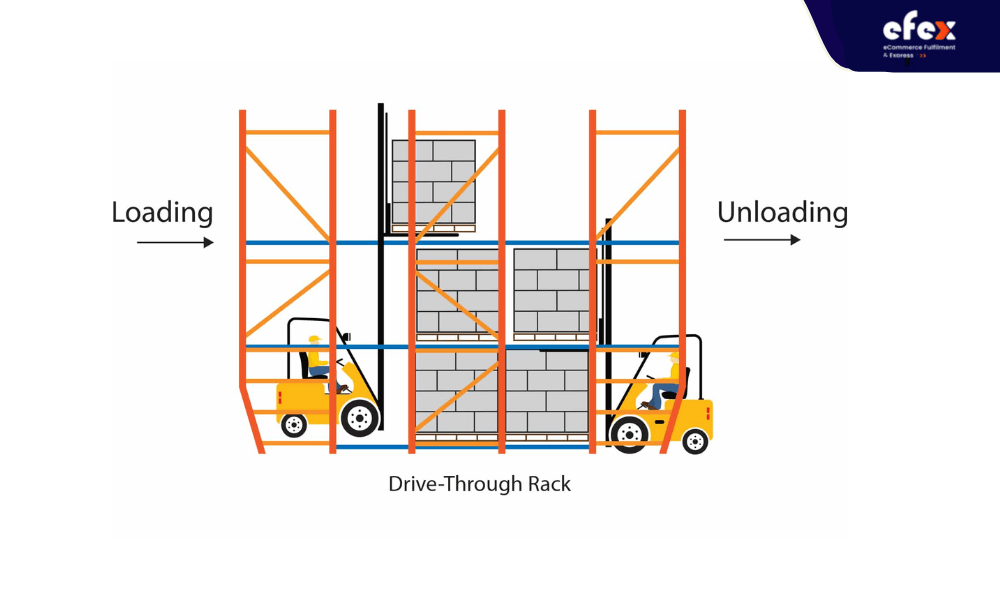

Instead of shelf beams, pallets are stored in rails. Forklifts have to drive into the structure to place pallets and remove them.

Pallets are stacked on a series of nested, movable carts that glide on tracks in this kind of racking. When a fresh pallet is loaded, the other carts are pushed back. It is ideal for warehouses with restricted space with consistent size and weight of products.

When using pallet flow racking, pallets flow down an incline on a system of rollers or wheels.

Each storage system has its own set of trade-offs. It may have a greater pick selective, but it wastes too much storage space that the warehouse can provide. You should consult with the stakeholders and experts, collect feedback from others to evaluate options, and choose the most suitable solution.

You can maximize warehouse space by installing racking over cross aisles and over dock doors. It is a simple way to increase warehouse capacity and space without increasing the square footage physically, and it does not obstruct the receiving, shipping, or forklift operation. Furthermore, it does not obstruct the receiving, shipping, or forklift operation. With this technique, you can look at the following ideas to understand how to maximize warehouse space.

👉 Read More: 20 Tips To Organize A Warehouse Efficiently And Productively

👉 Read More: Top 10 Ways To Manage A Warehouse Effectively

In conclusion, we hope that these 24 suggestions can help you optimize warehouse space, increase productivity, and save your costs. Remember that not all the above techniques are appropriate for every facility. You should consider carefully before choosing the most suitable warehouse space optimization techniques for your warehouse.