More Helpful Content

Carton flow rack system is considered a solution used by many businesses in storing goods. The carton rack helps to optimize the arrangement of goods, the space used in the warehouse is maximized, and because of its scientific nature, the working time of the staff and the number of other costs are also reduced. Be minimized. So what knowledge do you need to know before you want to apply the carton flow rack in your warehouse? You need to understand the definition, how it works as well as the types of carton racks available in the market.

The Carton Flow Rack, also known as Carton Live Storage, is a racking system that allows for the storage of multiple cartons and lightweight products. They are considered a solution for saving space and controlling the movement of goods in the warehouse. The Carton Flow Rack system ensures product transfer under the FIFO (First In, First Out) system like the direct pallet racking system.

Carton Flow Rack is widely used because of the benefits it brings, such as helping to classify the unloading and loading areas to avoid unnecessary intervention, reducing the distance covered in the warehouse, and reducing the time to operate. The system also helps to improve the working condition of some warehouses that still use outdated operating methods.

👉 Read More: What Is Cubic Capacity: Calculation, Benefit

👉 Read More: Cube Utilization: Formula And Calculation

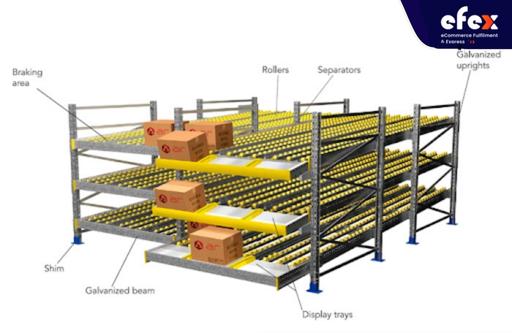

In the direct carton racking system, the goods will slide in the predetermined directions. Cargo vehicles are slightly inclined rollers that create other fast lanes. These rollers are easy to use and can be adjusted in the direction you want. Therefore, the goods are transported easily and as planned.

Carton racking systems are being chosen by many businesses as a solution to optimize storage and working space. Because this system brings a lot of benefits such as:

Selective racking is a heavy-duty type of racking system that is designed for storing products on pallets. Forklifts are used to move, load, and unload the goods.

These racking systems are commonly used in many industries and can withstand tough storage conditions such as freezing cold temperatures down to -60°C.

They are durable storage solutions that enable efficient organization and access to products stored on pallets in warehouses and distribution centers.

The Carton flow rack system is used in meeting the needs of storing goods in the warehouse. Therefore, the design will be customized to suit the specifics of the operation in each warehouse. Typically, Carton flow rack systems have input and output profiles, side profiles along with guide rails.

The versatility of direct storage cartons is also what makes them strong, they can vary specific elements of each field and installation such as platforms, display trays, brakes, systems, separation, etc.

If you want to optimize the workspace in the warehouse, definitely applying the Carton flow rack will be a good idea. Because it helps to solve problems related to inefficiencies in the warehouse operation, helping you to save costs for raw materials and human resources. Plus, it's also easy to install and move, so you can tailor it to how your business operates. Hope you have a good time with EFEX.