More Helpful Content

Since e-commerce was first brought to the Internet, online shopping has been booming. Especially during the Covid 19 pandemic, online sales have been more explosive than ever since.

However, due to recent events and the increasing accessibility of purchasing online, sales are greater than they have ever been. Billions of dollars are now being spent on online shopping throughout the world, and as the orders rise, businesses want more assistance to keep up.

Choosing the proper fulfillment center to collaborate with is one of the most helpful things you can do for your business. To do that, you should understand what is fulfillment center, how fulfillment centers work, and what is it different when comparing with Warehouses. Let's find out!

A fulfillment center is a location where sellers or companies that the sellers hire to outsource their fulfillment, such as third-party logistics providers, direct-to-consumer fulfillment, and business-to-retail fulfillment. The sellers fulfill wholesale orders to big-box retailers.

It is a third-party service provider that handles and sends the ordered products to your buyers. Fulfillment centers manage the mechanics of getting an order to a buyer’s door and support you in the packaging, address, and shipping of each item process. A fulfillment center’s primary job is to handle the seller’s inventory, store the goods, transport orders directly to consumers or merchants, and support sellers in operating the whole crucial but sometimes complex fulfillment process.

>> Learn more:

A micro-fulfillment center is a small, highly automated fulfillment facility that handles both e-commerce and in-store pick-ups.

Micro fulfillment centers comprise two major components: software management systems for processing online orders and physical infrastructure. It also includes robots to pick items from store shelves and transport them to packaging personnel.

Micro fulfillment centers, sometimes known as dark stores, are generally 3,000 to 10,000 square feet and can be integrated into shops or used as stand-alone facilities to service a cluster of locations. It can be located in a warehouse or an existing store, in a specialized small distribution or warehouse, small companies’ garages, parking lots, and basements.

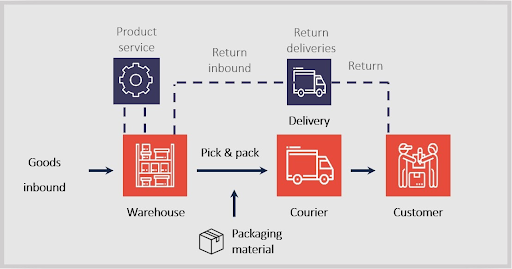

A fulfillment center is a central point for all logistical operations necessary to deliver a seller’s product to their buyers. It is often referred to as the order fulfillment procedure. You must first choose the most suitable fulfillment center for your company’s demand and store your product inventory there. Then, interfacing your online shops with the fulfillment center systems.

When an order is made, the provider obtains the relevant information from the seller. You should automate this procedure because it is inconvenient to manually trigger fulfillment requests every time a new order is finished on your online stores. When a buyer completes a transaction, merchandise is selected from the fulfillment center racks, packaged, and ready for distribution.

Besides, you can utilize fulfillment centers for B2B orders, which are often high-volume products supplied to bigger merchants. When a seller outsources fulfillment to a third-party logistics company, it will take care of the procedures on the seller’s behalf. It can involve storing, receiving, packaging, and transporting, as well as negotiating reduced shipping rates, handling high-volume demands, and frequently lowering fulfillment expenses.

However, sellers still take responsibility for some other order processing tasks. For instance, if a client receives an incorrect product, the seller must contact the consumer to resolve the problem. At that time, payment must be handled independently because most fulfillment companies do not offer payment processing.

Imagine a giant storage facility filled wall to wall with shelves, aisles, and loading docks to handle the huge volume and variety of items housed inside. This bustling commercial space is known as a warehouse – the engine room powering modern supply chains.

Warehouses enable companies to efficiently consolidate mass quantities of materials, components, merchandise or other goods under one expansive roof. This centralized approach allows for greater oversight and control compared to de-centralized storage. Sophisticated logistics technology tracks the intake, movement and order fulfillment of stock in real-time.

Far more than just static storage units, warehouses provide value-added services too. From quality assurance checks to specialized labelling, packaging, or light product assembly, they incorporate capabilities supplementing simple storage needs.

The result? Warehouses give companies enhanced supply chain flexibility, responsiveness and scale. No matter the size or throughput requirements, this industrial inventory hub mobilizes and distributes the items businesses depend on to fuel commerce and keep the economy humming.

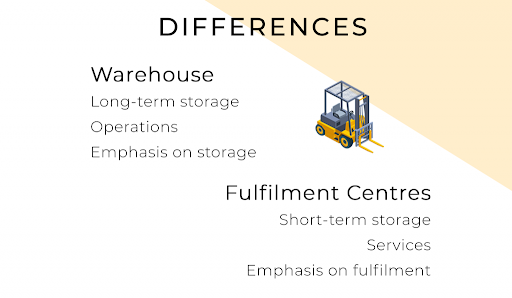

The phrases “fulfillment center” and “fulfillment warehouse” can occasionally be used interchangeably. However, each phrase might indicate a different meaning depending on the circumstances.

Both are enormous facilities that can contain goods for businesses that sell tangible things, whether through an online shop or a brick-and-mortar storefront.

Despite this resemblance, the services delivered and how they are used might vary greatly. A warehouse’s main role is to hold goods, but a fulfillment center is meant to improve the customer experience surrounding the ordering and delivery of products on time. This is achievable since sellers store their merchandise at a 3PL fulfillment center near their customers, reducing delivery time and saving costs.

👉 Read More: Order Fulfillment Cost: All of the Fee You Need to Pay

On the other hand, fulfillment centers concentrate on maintaining merchandise for limited periods and then sending products to consumers after customers place orders.

A warehouse is a component of a 3PL’s fulfillment center that holds a seller’s goods. But the major purpose of a fulfillment center is to conveniently manage the operations between the time a consumer makes an order and the time the product is delivered to their home or office. Merchandise will not be held in a fulfillment center for more than 30 days in the best-case scenario.

If merchandise must remain at a fulfillment center for an extended period, this may be termed long-term storage, and most 3PLs would charge a higher warehousing cost. Ideally, the seller and 3PL will often communicate regarding inventory levels.

A warehouse is usually dormant since it is only utilized to store merchandise. On the other hand, an order fulfillment center continuously buzzes with activity. Normally, a 3PL will offer end-to-end order fulfillment services, containing the following services at its fulfillment center such as receiving inventory, picking and packing, kitting goods if necessary, creating shipping labels, transporting orders, and handling returns.

A 3PL frequently has agreements with several shipping providers. Because a fulfillment center runs to complete B2B and B2C orders as quickly as they are placed, they require numerous firms to pick up shipments at least once a day and occasionally more as needed. This helps to ensure that orders are delivered within the client's specified time range.

According to the ways sellers send their goods, shipping providers may be required to pick up any orders with special delivery timeframes, such as same-day or next-day, at specific hours to assure on-time delivery. Certain carriers may have a regular time when they arrange pickups for both local and international cargo.

Typically, a fulfillment business will have a cutoff time for orders to the customers’ preferred delivery pace. For instance, an order may need to be placed before midday to ensure next-day delivery.

On the other hand, a warehouse will often arrange less frequent pickups because it is more cost-effective to ship out all things simultaneously, despite the customers’ preferred pace. The freight firms that warehouses utilize frequently demand at a specific time to pick up the items, which can cause a delay in delivery and provide the seller less flexibility in shipping rates.

Choosing the right fulfillment solution is critical for the success of any business, especially in the e-commerce industry. The needs of a small online shop differ greatly from those of a large retail chain, making it essential to assess your requirements carefully. The right solution will not only streamline your operations but also enhance customer satisfaction, improve scalability, and reduce costs.

To make the best decision, businesses need to evaluate factors such as order volume, storage needs, shipping destinations, and budget constraints. For instance, smaller businesses may benefit from simple, localized solutions, while larger enterprises might require a more comprehensive fulfillment center capable of handling complex logistics and high volumes of orders. Let’s delve deeper into why fulfillment centers are indispensable for e-commerce brands and explore an excellent solution for modern business needs.

Fulfillment centers play a vital role in the success of e-commerce businesses. They act as the backbone of operations, ensuring that customer orders are processed efficiently and accurately. Here’s how fulfillment centers add value to e-commerce brands:

One of the most significant advantages of a fulfillment center is its ability to manage the end-to-end order processing workflow. Picking the right products, packing them securely, and shipping them promptly are all labor-intensive tasks. Fulfillment centers are equipped with advanced technologies and trained staff to handle these processes seamlessly.

Real-time inventory tracking is a game-changer for e-commerce businesses. Fulfillment centers use advanced inventory management systems to monitor stock levels and provide businesses with up-to-date insights.

Running a self-managed warehouse can be expensive. Fulfillment centers help reduce costs through economies of scale.

For many e-commerce businesses, space is a premium resource. Fulfillment centers eliminate the need for in-house storage, freeing up physical space and allowing businesses to focus on growth.

For businesses seeking a reliable and efficient fulfillment partner, EFEX offers a cutting-edge solution tailored to meet diverse needs. EFEX combines technology, expertise, and customer-centric services to provide unmatched support for e-commerce brands.

EFEX stands out for several reasons, making it a top choice for businesses looking for reliable fulfillment services:

EFEX provides a comprehensive range of features designed to enhance operational efficiency and meet the diverse needs of businesses:

Businesses can focus on their core competencies while leaving logistics and fulfillment to the experts with only EFEX. EFEX’s innovative approach ensures that your brand delivers an exceptional customer experience, helping you stand out in a competitive e-commerce landscape.

Fulfillment centers like EFEX are indispensable for e-commerce businesses aiming to grow and succeed in today’s fast-paced market. By outsourcing logistics to a reliable partner, businesses can improve efficiency, reduce costs, and scale effortlessly to meet demand. Whether you’re a budding entrepreneur or an established brand, choosing the right fulfillment solution is the key to unlocking your business’s full potential.

Fulfillment centers are the behind-the-scenes engine that powers eCommerce, handling critical logistics like receiving inventory, order processing, picking, packing and shipping. As discussed, fulfillment centers provide companies with scalable infrastructure, expertise and cost efficiencies.

However, to fully realize these benefits, merchants need an advanced fulfillment partner capable of seamless multi-channel order fulfillment. EFEX offers integrated technology connecting all sales channels for unified order management and visibility.

With nationwide fulfillment centers located near key metro areas and populations, Efex provides fast fulfillment and affordable ground shipping. Their expertise and infrastructure enable online sellers to easily scale order volume across channels while optimizing the customer experience. By leveraging Efex’s end-to-end multi-channel order fulfillment solution, eCommerce businesses can focus their energy on sales growth and product innovation.