More Helpful Content

It's no surprise that delivering the last mile of a product makes up 41% of the total cost of the supply chain, according to a report by Capgemini.

Big companies like Amazon and Walmart can offer two days or even same-day delivery which proves to be more cost-effective in terms of both infrastructure and shipping expenses. However, not all small companies can do that to keep up with this swift pace.

Fear not! There's a new way: Micro fulfillment. This strategy makes the last part of the delivery shorter and cheaper by skipping the need for retail stores or pricey fulfillment services. And customers still get their things fast.

So, what exactly is micro fulfillment? If this concept is new to you, then this comprehensive guide on micro fulfillment is just what you need.

Let's jump in!

Micro fulfillment is a speedy order fulfillment system, featuring high-density and localized storage. Its design aims to complete orders within hours using advanced technology on a smaller scale.

These systems are designed for tight spots in busy urban areas, bringing distribution centers closer to the end consumers for faster deliveries.

The primary goal of micro fulfillment is to reduce the time and distance it takes to fulfill and deliver orders. This concept has gained prominence with the growth of e-commerce and the increasing demand for faster and more efficient order fulfillment.

>> Learn more:

Micro fulfillment centers (MFCs) are small, highly automated storage facilities designed to store inventory and optimize the process of picking, packing, and shipping products for online orders directly to the end customer.

These centers are notably smaller than conventional distribution centers or warehouses. They are strategically located in proximity to urban or densely populated areas.

MFCs can be in existing stores or dedicated small warehouses. The size of MCFs can vary, but they are typically around 3,000 to 10,000 square feet, holding up to 15,000 different items (for example, Takeoff Technologies’ centers).

Besides, MFCs also keep enough stock for about a day or two of work and need to be filled up regularly.

What makes MFCs even cooler is the integration of advanced technologies. This helps them fill orders way cheaper—about 75% less. The notable pioneers are Two big MFCs - Amazon and Walmart.

While Amazon gets fewer incidents and fewer lost-time incidents by deploying more than 750,000 robots, Walmart chases higher profits by using warehouse robots and automated claws.

As more people shopped online, it became hard for e-commerce to keep up with finding products. The traditional way of restocking stores wasn't ready for this much online shopping.

Using a system like an MFC makes it easier for stores and online sellers to handle orders better by bringing online shopping capabilities to places where products are already stored

Just like micro fulfillment, micro-warehousing is about using space differently than traditional warehouses. The idea is to bring products closer to customers for faster order handling.

This strategy is great for quickly fulfilling orders, whether customers pick up in-store or get home delivery.

Micro-warehousing meets the modern need for quick and responsive order handling in online shopping. It fits into the bigger plan of streamlining logistics and reducing delivery times in the era of e-commerce.

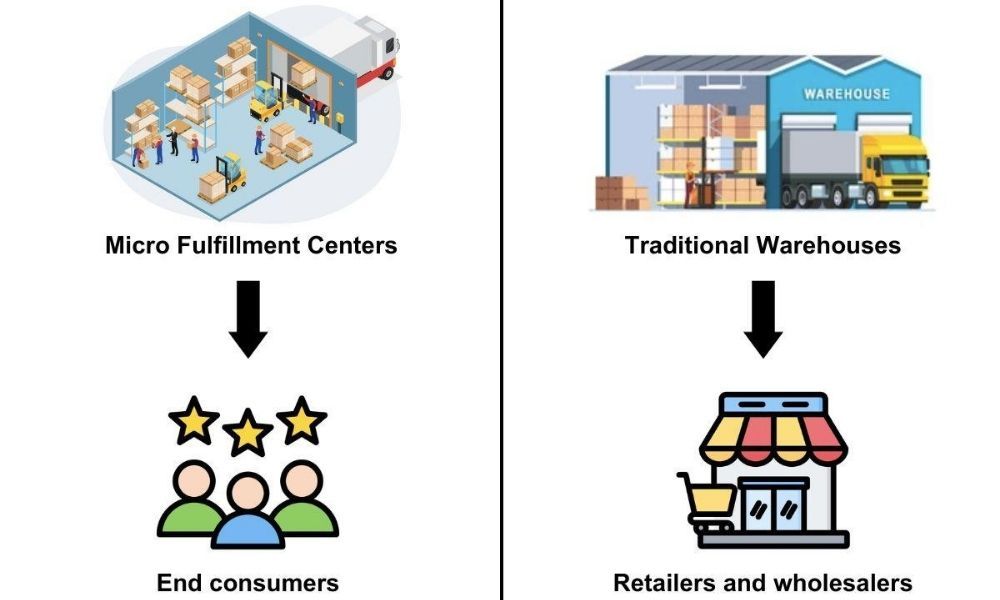

Micro fulfillment centers are tailored to the demands of e-commerce and emphasize efficiency, speed, and proximity to customers. In contrast, traditional large-scale warehouses serve a broader logistical purpose, characterized by their larger size and extensive scope of operations.

Here are some key differences:

MFCs are compact, typically not exceeding 10,000 square feet, with a smaller footprint. Larger traditional fulfillment centers usually span around 300,000 square feet but can be significantly larger based on operational scale.

MFCs are often strategically located closer to urban areas to facilitate faster last-mile delivery, while larger traditional warehouses are often located in more remote areas with ample space for storing a vast inventory.

MFCs concentrate on rapid and efficient order fulfillment, particularly for online orders, placing emphasis on quick processing and last-mile delivery.

These centers are not intended for prolonged storage but rather for keeping products ready to pick, pack, and ship upon receiving orders.

Traditional warehouses, on the other hand, serve a broader role. They manage large-scale storage and distribution for both retail and wholesale purposes.

Larger fulfillment centers possess sufficient space for storing substantial inventory, lasting several months without frequent replenishment.

MFCs are often designed to be modular and scalable, allowing businesses to adjust their size and capacity based on fluctuating demand. In contrast, larger traditional warehouses may be larger and less flexible in terms of quick adjustments to changing inventory needs.

While retailers highlighted the need for faster online order fulfillment, traditional fulfillment centers might struggle with this demand. However, micro fulfillment trends can offer a solution with some main benefits as follows.

Local fulfillment centers, when combined with eco-friendly delivery vehicles, have the potential to significantly reduce the environmental impact of e-commerce logistics.

Alternative transportation methods not only cut greenhouse gas emissions but also alleviate traffic in congested urban areas, especially by using bicycle messengers.

Most micro fulfillment companies apply automated micro fulfillment to optimize order processes.

Automation, including the automatic generation of picking lists and machine-assisted processing, significantly expedites order fulfillment, ensuring prompt dispatch shortly after order receipt.

Micro fulfillment breaks away from depending on a limited number of central distribution centers for delivering goods. Instead, it employs smaller, decentralized warehouses in densely populated urban areas, bringing the quicker logistics process nearer to the end consumer.

Companies using MFCs make customers happier with faster deliveries. Being close to customers helps process returns and refunds quickly, adding to overall customer satisfaction.

Moreover, many MFCs also act like local stores where customers can pick up their orders, saving them from waiting for shipping and giving them more choices for delivery and pickup.

MFC provides a budget-friendly option compared to the setup and operation costs of large fulfillment centers, which can be financially challenging for smaller businesses.

While there might be some limitations on capacity, MFCs are scalable, allowing brands to expand their operations without the need for significant investments.

Offering fast and affordable shipping through MFCs eliminates common barriers for consumers, such as long shipping times and high shipping costs. This improved customer experience leads to increased sales, generating higher revenue that, in turn, facilitates business scaling.

Micro fulfillment can cut fulfillment costs and make deliveries faster, making it an attractive option for businesses aiming to improve operations.

Yet, it's crucial to be aware of the challenges that come with using micro fulfillment centers.

Even though being close to main markets is a big plus for micro warehousing, its dependence on where customers are located means it can be affected by changes in the market and shifts in customer preferences, necessitating ongoing reassessments.

MFCs with their limited storage need constant replenishment of inventory. Operating for only 24-48 hours, it's essential to proactively reorder stock, and this often requires an automated system.

Besides, regularly transporting goods between locations comes with additional costs to consider.

Consumer demands influenced by unpredictable events like COVID-19 are hard to foresee. The limited storage in micro fulfillment center makes it challenging to quickly adjust to sudden changes in demand. This leads to slowing down the response to unexpected market shifts.

Micro fulfillment centers may not always have enough products due to their limited space. Stockouts disrupt the supply chain, resulting in disappointed customers for businesses. This may be more terrible when unpredictable changes in customer trends occur.

While many micro fulfillment centers use advanced automation for better efficiency, this may not be ideal for all kinds of products, especially larger items. Handling heavy items like furniture and large appliances can cause considerable wear and tear on the machines.

Additionally, large product variations take up more space, leading to the necessity of storing fewer items to fit within the storage limits of micro fulfillment centers.

If your company can't or doesn't want to use a micro fulfillment strategy but still needs to offer customers quick delivery, quality, and personalized fulfillment, come to EFEX!

EFEX Micro-Fulfillment solutions offer scalable options for business growth. The choice of the right partner is crucial for future success. Our services include:

Our pre-planned, adaptable, and expandable solution addresses different throughput and capacity requirements. We use our knowledge to swiftly and consistently provide you with a competitive edge in your supply chain.

As an EFEX customer, you won't bear the risk of setup or additional fees, allowing you to scale and future-proof your business growth effortlessly with us.

This guide has come to an end. Micro fulfillment center business model might be the answer to effectively utilizing your business's resources and assets in order to ensure long-term growth and expansion.

This strategy is especially true for smaller e-commerce businesses that strike the balance between accelerating the order process and core development.

Let EFEX lift you a hand! Contact us today to be rest assured of each product shipped!