More Helpful Content

A buyer receives an order form when they make a substantial order with a provider. The supplier can then cross-check the order form against the products received a note to confirm that all items were delivered to the buyer. This form is especially useful when an order contains products that are back-ordered or out-of-stock. The use of the goods received note can help to prevent transaction mistakes.

The goods received note can potentially be used to settle future disputes. The order is not just touched by the customer and the provider. The transaction also includes a delivery person.

If a dispute develops, the goods received note can be used to determine who is to charge. Let’s dive into this article to understand the importance of the goods received note (GRN) and find out its form that has been widely used between businesses and suppliers.

A Good Received Note, also known as a delivery note, is a document that confirms the formal receipts of goods or services by clients. This document can be used as a verification of products supplied by both suppliers and buyers. The good received note or GRN, which is frequently supplied with an invoice, should always be retained and saved so that the procurement department or AP can refer to it at any time.

For example, when the customer gets the items, the store’s department will inspect them for compliance with the purchase order and physical condition. It will issue the GRN after ensuring that all products are received in perfect physical condition. If the items received do not meet the criteria of the purchase order, the customer can reject them.

They only issue GRNs for accepted products and issue a new purchase order for the rejected batch. The store’s department is in charge of issuing GRN. It is created in many copies, one for the supplier, one for the procurement department, one for the accounts department, and one for the store’s department.

👉 Read More: What Is Handling Fees? Calculation And Example

The goods received note serves as a means for both parties to affirm that they have fulfilled their obligations under the contract and save that record for future reference, should it be necessary or if disruptions are caused. There are some examples:

When a supplier delivers required items, it is considered that it is done in good faith, for example, the things given are in accordance with the specifications requested and will pass quality inspections.

However, the client cannot just take the supplier's word for it. The procurement or finance division then delivers the items to the requesting department for assessment to ensure that they fulfill their requirements and quality criteria. If the suppliers in question are satisfactory, goods received notes are sent to the counterparties, certifying that the supplies meet requirements and assisting in the avoidance of future problems over quality or amount supplied.

Assume that once the materials are delivered, the department inside the asking company discovers a problem that they did not identify at the outset. A deeper examination of the items received notice reveals that functionality was tested and operated properly.

At this point, the provider is free to replace the supplies provided in good faith or require that the clients find a way around it because the items were in excellent condition when delivered.

The three-way matching procedure is a powerful tool for minimizing and eliminating billing fraud in businesses of all sizes. Supplier invoices are matched with supply request notes and items received notes using the three-way matching procure. When taken collectively, these prove:

It is simple to spot abnormalities and catch fake invoices using this strategy.

Goods received notes, for example, are notifications that an organization has received items that were requested. This should subsequently be reflected in warehouse data for delivered supplies. As supplies are made, goods received notes are utilized to manage inventory and retain an accurate inventory of warehouse numbers.

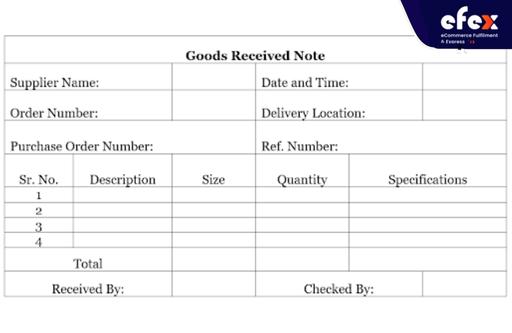

The goods received note assists both consumers and suppliers in reaching and maintaining binding agreements, as well as allowing enterprises to keep track of inventory levels. It contains the following information:

There is always the possibility of an issue arising in procurement. The sensible approach is to anticipate these challenges and design systems and procedures to address them, providing both sides with a positive customer-vendor experience. The following are some challenges you could face while dealing with goods received notes, whether you are ordering or supplying items.

Whenever a supplier makes a delivery, a GRN should be issued. However, in many circumstances, this is not the case since the department inside the business that orders the items must inspect the delivered supplies to verify they are up to quality. This might generate issues since issuing suppliers must wait till the customer has completed their due diligence. If the company is huge, GRNs might take up to a week to be given.

Assume that when testing the given items, the procuring organization detects a flaw or two with the goods sent to them. Smaller firms may be able to notify suppliers immediately. On the other hand, larger businesses may simplify filing it as an issue for some personnel to handle.

This causes needless delays in both the client’s and the supplier’s operations because the procurement organization is left with worthless items and the vendor is locked up with both inventory and cash with the buyer.

👉 Read More: What Is Material Handling Cost? Formula And Example

The GRN is distributed in three copies to the ordering department, the procurement department, and the supplier. During the recording process, it is simple for one department to overlook a minor item in their own copy, which causes delays when it comes time to pay the supplier’s invoice. Furthermore, this might lead to supplier bills collecting late payment interest.

Managing GRN is an arduous administrative effort. Managing difficulties with GRNs is significantly more difficult. Consider a scenario in which the procurement department is tasked with untangling each issue, personally calling both ordering departments and suppliers to attempt to establish a middle ground. This increases the administrative burden on procurement while adding nothing to the bottom line.

No matter how strict your vetting methods are, one poor item of merchandise may slip between the cracks. And when that happens, you obviously seek retribution from your suppliers. This might be a problem because the provider in question has already performed comprehensive tests to verify quality and quantity compliance. Therefore, the expense of these errors found later on may be tough to bear.

To represent comprehensive delivery details, a GRN must include the following elements:

The goods received note serves as tangible documentation of receipt of goods. It aids in the maintenance of inventory records and guarantees that the appropriate number of items is always accessible. GRN aids in the resolution of disputes that may develop as a result of defective items supplied. It is used to reconcile supplier invoices with the products received in order to make proper payments. It is also documentary proof on which accountants may rely to keep accurate account balances. Hope you have a good time with EFEX.

>> Explore more our End-to-End Order Fulfillment Solution