More Helpful Content

In the world of online shopping, a single missed delivery or inaccurate order can drive your customers to competitors. Order fulfillment rates are more than just statistics—they now directly impact your brand reputation and customer loyalty. The question is, are you confident in your current fill rate? And how can you improve it effectively?

Deeply aware of that, this article will delve into the key knowledge of order fill rates:

Without further ado, let’s get started!

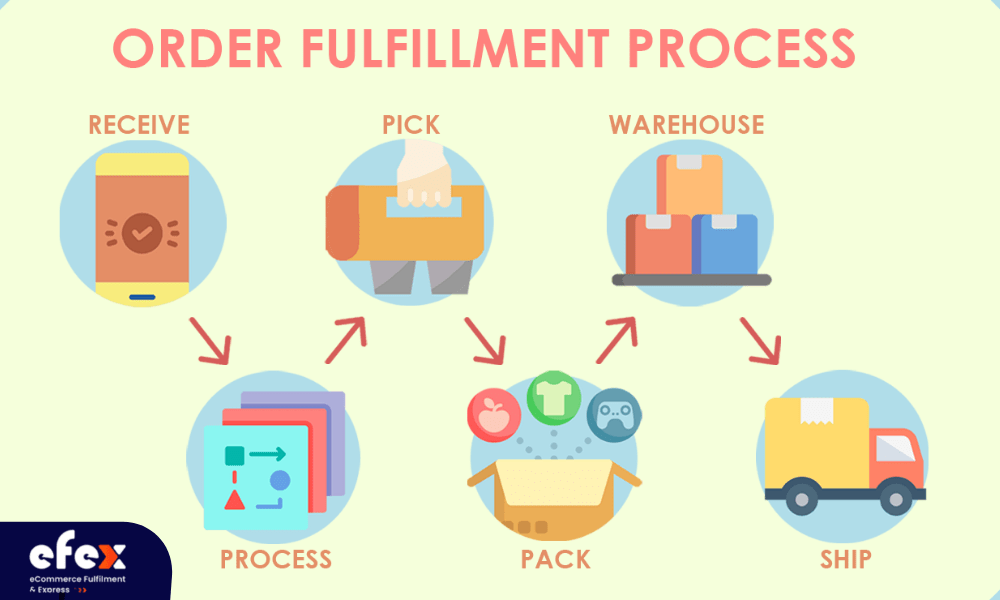

Before we discuss the order fulfillment rate definition, it's essential to understand the core concept of order fulfillment. Generally, it is the entire journey of an order, from when a customer clicks "buy now" on your online store to the instant they receive their package.

But how do we measure its effectiveness? That’s when "order fulfillment rate" (or fill rates) comes into play. The order fulfillment rate meaning is to show the percentage of orders you successfully shipped without encountering hiccups. The higher the order fulfillment rate is, the more efficient your system is. This way, you’ll gain happy customers, positive reviews, and, ultimately, a thriving business.

The order fulfillment rate (fill rate) is defined by dividing the number of orders already received by the total number of orders handled. It indicates how well the fulfillment service providers handle the shipping process. A higher fulfillment rate can be a competitive advantage for a provider in the market competition. Also, it can point out the bottleneck of the business and facilitate continuous improvement.

>> Learn more:

Understanding your overall order fulfillment rate is crucial, but sometimes, you need a more granular view to identify areas for improvement. That's where these additional fulfillment rates come in, offering valuable insights into specific stages of your supply chain.

Inventory fill rate = (Number of Units Successfully Delivered)/(Total Number of Units Ordered)*100

First of all, inventory fill rate is a fundamental metric that shows how effectively you're meeting customer demand with the current inventory levels. It also reveals what percentage of all incoming orders you can fulfill immediately without facing any stockouts or delays.

A high inventory fill rate indicates a healthy balance between having enough stock to satisfy customers and avoiding the risks and costs associated with excess inventory. To calculate this fill rate, divide the number of units shipped without delay by the number of units demanded (or ordered) within a specific timeframe, then multiply by 100.

| Line fill rate = (Number of Order Lines Completely Fulfilled)/(Total Number of Order Lines) *100 |

While the inventory fill rate provides a broad overview, the line fill rate drills down to the individual product lines within your orders. Accordingly, it measures the percentage of individual product lines you can fulfill completely with the available inventory. This way, this fill rate helps to identify potential bottlenecks in your picking and packing processes.

For example, if a customer orders three different product lines and you only have two in stock, your line fill rate for that order would be 66.6%.

| Case fill rate = (Number of Cases Shipped)/(Total Number of Cases Ordered) *100 |

Similar to the line fill rate but focusing on the packaging, the case fill rate measures the percentage of ordered cases that can be shipped completely without being broken down or split.

Indeed, this rate is most relevant for businesses that ship products in bulk quantities rather than individual units. A high case-fill rate signals efficient warehouse operations and streamlined picking processes

| Warehouse fill rate = (Number of Orders Completely Fulfilled from Warehouse)/(Total Number of Orders Received by Warehouse)*100 |

Shifting our focus to the warehouse level, the order fill rate measures the percentage of orders that a specific warehouse can fulfill completely using its own inventory.

Businesses operating multiple warehouses or fulfillment centers can identify potential bottlenecks in their distribution network by tracking this fill rate. It also helps merchants optimize inventory allocation across different locations and ensure that orders are routed to the most efficient fulfillment center.

| Warehouse fill rate = (Quantity Received from Vendor On-Time)/(Quantity Ordered from Vendor)*100 |

Looking beyond your own operations, the vendor fill rate shifts the focus to your suppliers' performance. It tells you what percentage of the items you order from your vendors arrive on time and in the correct quantities. This way, the fill rate measures how effectively your vendors meet your purchase orders and deadlines.

Finally, this term is often used interchangeably with "order fill rate" (or order fulfillment rates). In a general sense, it measures your overall ability to fulfill orders immediately with available inventory. Indeed, it's a fundamental indicator of your inventory management and order fulfillment efficiency.

In the next section, we will guide you thoroughly on calculating the order fulfillment rates.

However, it’s worth noting that the specific calculation might vary slightly depending on whether you're measuring orders, units, or dollar value.

Now that you understand the different facets of fulfillment, let's focus on the core metric—your overall order fulfillment rate. This number will give you a quick snapshot of your fulfillment operation's health and highlight potential areas for improvement.

To calculate the order fulfillment rate, divide the number of "delivered" orders in the previous 90 days by the total number of orders and then multiply by 100%.

Expressed mathematically, it is:

Note: this calculation excludes "Canceled" orders.

Let's illustrate this with a real-world example. Imagine you run a successful online toy store that receives around 100 orders per week. In a typical week, you successfully ship 85 orders complete and on time. However, 5 orders face delays due to unexpected stock shortages, and another 10 are canceled by customers before they can be shipped. Plugging these numbers into the formula, your fulfillment rate is (85 / 100) x 100 = 85%. This means your order fulfillment rate for that week is 85%.

It’s worth noting that some performance calculators will delete "Rejected" orders from calculations automatically. Even if you've only had one "Disapproved" order or reservation in the preceding 90 days, you'll see a 100% completion rate.

👉 Read More: Ecommerce Order Fulfillment Guide: Process And Strategy To Improve

While attracting customers to your online store is crucial in the fast-paced world of e-commerce, efficient and accurate order fulfillment truly solidifies brand loyalty and fuels sustainable growth.

This is why a healthy order fill rate can translate to a positive domino effect across various aspects of your business, which are:

In the digital world, where customers share their good (and bad) experiences with everyone, reviews and ratings hold immense power. They are also more likely to recommend your brand to friends and family when they know they can rely on you to deliver their packages as promised. Hence, if you consistently deliver orders on time and exactly as expected, it builds a strong foundation of trust and reliability.

Indeed, it’s much easier to keep a happy customer than to find a new one, especially when they have countless options at their fingertips. Therefore, you must consistently exceed their expectations with a high order fill rate. When the buyers know they can rely on you to receive the right products on time and without hassle, they are much more likely to shop with you again and again.

Your order fill rate isn't just about making customers happy; it also acts like a report card that provides valuable insights into the efficiency of your internal operations. A low rate signals potential bottlenecks in inventory management, order processing, or warehouse operations.

By paying attention to your fill rate, you can spot these problems early and fix them before they become big headaches.

The order request is usually sent to the main office as soon as the staff confirms the customer's request. However, because the approval process is still done manually, it might be less seamless and transparent. Sales order confirmations, for example, maybe misplaced or duplicated, resulting in orders being doubled or not received at all.

Not to mention the time it takes for the salesman to return to work. Because the B2B process is more complicated, even a minor hiccup can significantly influence future customer relationships.

Forecasting market demand and developing a purchasing plan are critical tasks in balancing the company's orders. If they run out of stock due to their late arrival, consumers may move to a competitor's service. This will have a negative impact on your firm, as the number of consumer orders is likely to decrease.

As a result, you should anticipate market demand with the greatest accuracy. If you do so, the commodities in your warehouse will be guaranteed in quantity, allowing you to correctly fulfill each customer order.

Because B2B order fulfillment entails shipping in bigger numbers, the order value is significantly higher and frequently necessitates more staff with specialized equipment (pallets, vehicles, etc.). Large organizations may run numerous warehouses (multi-warehouses). These warehouses are occasionally dispersed around the country in order to accommodate the requests of different areas.

However, because the degree of storage in the warehouses varies, the multi-warehouse type will generate issues. Transparent chronological inventory data is essential for a site administrator to be able to assign which warehouses will best fulfill certain client requests. Manually counting inventory, coordinating workers, and processing orders may be difficult and time-consuming. Any delay or inaccuracy on the basis might damage the company's reputation, not to mention the loss of goods or services.

We now agree that the order fill rate is the backbone of happy customers, repeat business, and, ultimately, a thriving bottom line. However, achieving a consistently high order fill rate is another issue. Navigating a complex maze with countless moving parts, from inventory management to shipping logistics, can make it easy to feel overwhelmed.

Worry not; these are some tried-and-true strategies to optimize your fulfillment operations:

Efficiency is king when it comes to order fulfillment. Every extra step and unnecessary delay adds friction to the process, increasing the likelihood of errors and eating into your profit margins.

To avoid this, start by mapping out your current fulfillment workflow and identifying any bottlenecks or areas where things get bogged down. You also need to look for opportunities to simplify and automate tasks like order routing or label printing. These help to minimize human error and speed up processing times.

In addition, implementing a robust order management system (OMS) can provide a centralized platform to track orders, manage inventory, and automate customer communication. This translates to fewer errors, faster processing times, and more orders shipped out accurately and on time, directly contributing to a higher order fulfillment rate.

Accurate inventory data is indeed a crucial element for a successful fulfillment operation. Without real-time visibility into your stock levels, you're essentially increasing the risk of stockouts, inaccurate orders, and frustrated customers - which finally lowers the order fulfillment rates.

Therefore, it’s important to implement robust inventory management software, ERP systems, or distributor software like Distribution Management Systems that integrate seamlessly with your sales channels. These systems allow you to keep track of inventory levels in real-time, receive automatic low-stock alerts, and identify the hot SKUs to make informed decisions about stocking or reordering items.

In the world of online shopping, fast and reliable shipping is everything. Customers receiving their orders on time and as expected reinforces their trust in your business, which translates to a positive overall experience and high order fulfillment rate.

To make it a reality, you should team up with a trustworthy shipping company with a good track record and, if possible, provide different shipping options. Don't forget to provide tracking information so customers can follow their package every step of the way.

Many might consider product returns implausible to a high order fulfillment rate. Quite the opposite, returns are valuable information sources that can help you fine-tune your fulfillment process for even better results.

Indeed, by closely examining the reasons behind product returns, you can identify patterns that point to areas for improvement. Perhaps your product descriptions aren't clear enough, leading to confusion about sizing or variations. Maybe there are issues with the packaging that are causing damage during delivery. Addressing these root causes can prevent future returns, minimize errors, and ultimately boost your order fulfillment rate.

If you are looking beyond to enhance your order fulfillment process, team up with a reputed fulfillment service provider. At EFEX, we understand the critical importance of a smooth, efficient fulfillment process. We've designed our services with a laser focus on speed, reliability, and scalability, so you can say goodbye to fulfillment bottlenecks and hello to a sky-high order fulfillment rate.

Our Hanoi and Ho Chi Minh City warehouses and our extensive logistics network will ensure faster delivery times and reduced shipping costs for you and your customers. Over and above that, our professional team handles every package with care, while our sophisticated order management system (OMS) streamlines the entire process, from order placement to final delivery. You can track your orders in real-time and gain valuable insights into your fulfillment performance using EFEX fulfillment services.

The perfect order fulfillment rate for efficiently fulfilling customer orders is 97-99%. This means shipping 97-99% of products ordered within the expected timeframe. Striving for 100% is unrealistic due to factors like inventory inaccuracies and supplier issues.

While 85-95% is average for most companies, achieving a 97-99% fill rate ensures superior customer service and minimal backorders and stockouts. EFEX's distributed fulfillment centers and automation tools like OMS have enabled companies to achieve a 97-99% fill rate while quickly shipping 10,000-20,000 units.

The fill rate of a purchase order, or the vendor fill rate, measures how effectively your supplier fulfills your orders. It tells you how many percentages of the orders you receive from the vendors arrive on time and in the correct quantities.

For example, if you order 100 units and receive 85 units on time, your purchase order fill rate is 85%.

While both fill rate & service level relate to fulfillment success, they measure different aspects:

The order fulfillment rate or fill rate is a key metric for eCommerce businesses, measuring how efficiently orders are processed and shipped. As discussed, a high fulfillment rate depends on streamlined systems, real-time inventory visibility, and fast shipping. However, fulfillment is complex, and scaling order volume often requires help.

By partnering with Efex for hassle-free eCommerce fulfillment, online sellers gain nationwide infrastructure, advanced technology, and logistics expertise to achieve excellent fulfillment rates.

Efex removes the operational burden through integrated, end-to-end services tailored to each merchant's needs. With Efex as their fulfillment partner, eCommerce businesses can focus their energy on sales growth and product innovation while trusted experts handle order processing, inventory management, and fast shipping to delight customers. Leveraging Efex's Hassle-free E-Commerce Fulfillment solution optimizes the fulfillment rate at scale.