More Helpful Content

Order must be promptly released. Without it, a mix-up might occur, halting production and potentially costing the company money. Therefore, it's crucial to time a release order to precisely when the business is ready to begin production. Therefore, planned order release is essential. We'll discuss its concept, calculation, and examples in today's topic.

Planned order release is the scheduled date that is set aside for an order to be released. Requesting this quantity of a product within the allotted time limit will guarantee that it is delivered when required. By weighing the order's receipt and its acquisition lead time, the release of an ordered request is decided.

The timeframe for firming or discharging an agreed-upon request is affected by the predefined lead time until the scheduled receiving date. In accordance with the choice of a discharge date time period, several systems offer the selection and evaluation of planned requests. MRP continuously strives to follow the ace generating plan's delivery timetable for the final outputs.

👉 Read More:

The main basis for planned order releases can be understood when the predicted availability is negative or below zero. This means that all of the inventories have been used up and new orders must be made. A confirmed order is always a scheduled order that has been calculated after netting out the inventory.

It varies from anticipated order releases as a result. A considerably more likely event is one that is the subject of a planned order release.

Thus, it is run by an MPS, a computer-generated program that maintains a schedule and keeps track of the expected orders. The MPS won't place any additional orders if the predicted available balance becomes zero during a predetermined time period. Nevertheless, once the allotted time has gone, it will generate an order after netting and evaluating the stock that is currently in stock.

In a scenario with fixed orders of 125 units for a make-to-stock environment, there are 110 units in the inventory to begin. When are new orders (quantities) required to meet anticipated demand? It’s time you need the formula for the Planned order release with the demand for 12. The formula is as follows:

Planned order release = Beginning Inventory + MPS shipments - Forecasted Demand

The lead time for dependent-demand products is calculated using the MRP, and the scheduled release date is then set. This tactic can help planners using MRP systems in adjusting to material and capacity constraints by solidifying a few well-chosen scheduled orders. The master production schedule is often expressed in terms of orders that are definitely planned.

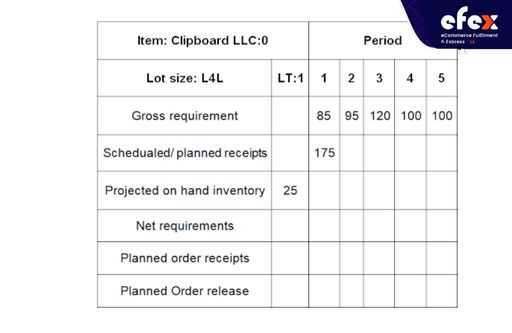

In this case, MRP Matrix will be a tool for calculating the planned order release.

👉 Read More: What Is Dead Stock In Inventory Management?

👉 Read More: What Is Kitting In Manufacturing: Process and Benefits

Here, we have an example of MRP Matrix:

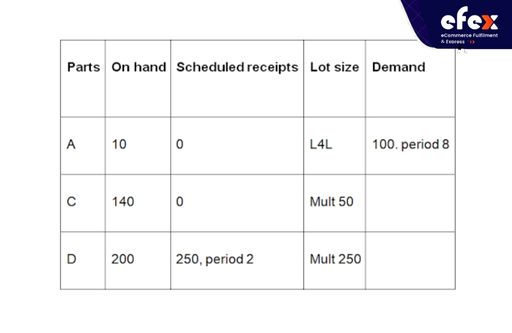

Given that A with LT=3, C with LT=4, and D with LT=2, determine the planned order release for A, C, and D as well as when they should be released based on the information in the MRP matrix. You can get the answer in the following table:

👉 Read More: What Does A Backorder Mean: Managing Tips and Solutions

👉 Read More: Order Management System: Definition, Process And Value

👉 Read More: Order Management System For Ecommerce: Definition, Key Effect, Benefit

Planned order release refers to the first step in processing an order for a customer. The order form should list the items ordered, the shipping method, the estimated delivery date, and any other details that may affect delivery. Effective order fulfillment relies heavily on a company's ability to efficiently manage this process through effective scheduling practices, accurate forecasting systems, and efficient inventory management systems.