More Helpful Content

How do you determine when it's time to order more stock? You probably relied on your instincts in the early stages of your company. You'd eyeball your stock every two weeks, guess what you'd run out of in the next five days, and place an order. Running on instinct isn't scalable when your business grows and your duties expand. Things start to slip as your operations and product master data become increasingly complex.

For example, you may arrive on Monday morning and discover that you are out of a crucial product. Orders are coming in from customers, and you recall that your provider has a one-week lead time. Meanwhile, you can only hope that your consumers will remain patient or bear the financial consequences of missing sales.

So, how can this be avoided in a developing business? Using historical data to create the reorder point (also known as reorder levels) will ensure that your company's inventory levels are always healthy.

Reorder Point is a popular method of inventory control. The ROP system keeps track of your inventory levels and orders more when they go below a specified threshold. Some businesses additionally factor in safety stock in their estimates to ensure they never run out of product.

There are numerous advantages to employing this technique, including better efficiency and lower expenses for over-or under-ordering products. This will help to ensure that there are no interruptions and will save money. Because each item has its own relevance and usage rate in the manufacturing process, the reorder point varies. It is also affected by a number of other elements, such as discounts, the item's shipping time, safety stock, and so on.

👉 Read More: Backorder Cost: Meaning, Importance and Formula

With the advancement of ERP, this process has become automated and hence quite simple to carry out. Everything important is tracked and taken care of in the system. Early ordering also helps cut down on high vendor prices and facilitates good negotiating.

If you employ reorder points, you won't be late with your next shipment of items. You'll always have adequate stock to meet customer demand if you have an appropriate reorder point for each SKU - without locking up unnecessary money in inventory.

Keeping more goods on hand than may be sold timely is not considered a good use of money. Reorder points give organizations more financial freedom by permitting them to maintain the bare minimum of goods inventory without being out of stock.

Too many goods in the warehouse are costly, while too little good can lead to stockouts that are detrimental to your business: The requests for orders are canceled or delayed, consumers are lost, and your reputation can suffer as a result. Reorder points aid in the prevention of stockouts first and foremost.

Determining to reorder points is inextricably linked to understanding consumption trends over a certain period of time. The more reorder points you compute for each product, the better you will anticipate future demand and make sure that you are using the reorder quantity method correctly.

The following are some of the benefits of being precise when determining the reorder point in inventory control.

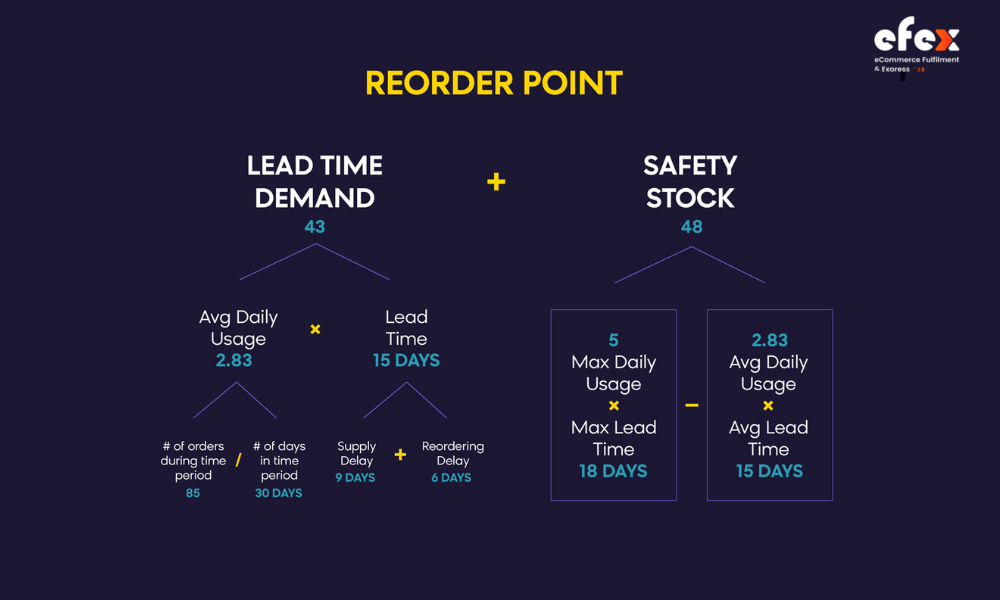

You can calculate reorder point by using the following formula reorder point:

The reorder point formula is a mathematical calculation that businesses use to determine the minimal amount of inventory required to avoid running out of stock. The formula for calculating reorder point is as follows:

| Demand during lead time + safety stock = Reorder point (ROP). |

Knowing the usual need for a product isn't enough because demand can spike unexpectedly, or issues with a provider can prohibit you from refilling inventory as rapidly as you'd like. As the name implies, safety stock is extra "just in case" inventory held on hand to anticipate demanding or supplying changes.

| Safety stock level = (Max daily orders x max lead time) – (average daily orders x average lead time) |

To determine the appropriate level of safety stock for a certain product, let's do the following steps:

Now let's return to our reorder point formula: Simply add the lead time demand and safety stock calculations together, and you've got ROP.

Businesses that keep additional stock on hand in case of unforeseen occurrences adopt this strategy. Multiply the daily average usage by the lead time, then add the amount of safety stock you retain to get a reorder point with safety stock.

| ROP = (daily average usage * lead time) + safety stock |

Let's look at an example to help you understand. Assume you're a perfume shop that sells 300 bottles of perfume per day. Each batch of perfumes you order takes two weeks to arrive from your merchant. In case of unanticipated delays, you keep enough surplus stock for 7 days of sales. What should be your reorder point now?

When you have 2400 bottles left in your inventory, you should make an order for the next batch of perfumes.

Businesses that adhere to lean inventory methods or a just-in-time inventory management strategy typically do not maintain safety stock. In such circumstances, the reorder point can be determined by multiplying your daily average sales by your lead time. When you do not have a safety stock, your reorder level and frequency of orders are typically higher.

| ROP = daily average sales x lead time |

Using the preceding perfume example, excluding safety stock, your ROP should be: ROP = 300 x 14 = 4200 bottles. When you have 4200 bottles remaining, you should place an order for the following batch of perfumes.

The number of days that pass between purchasing order from your manufacturer or supplier for a product and getting the product is referred to as the lead time. When compared to a domestic or in-house production plant, your lead time will be lengthier if your supplier is located overseas. To calculate demand lead time, let's multiply the product's lead time (in days) by the average number of units sold daily as the formula below:

| Lead time demand = lead time x average daily sales |

👉 Read More: Probability Of Stockout: Formula And Calculation

You can get things for your inventory from a variety of vendors, and each vendor has a distinct lead time. As a result, it's important to consider your reorder point on an item-by-item basis. Assume you're a retailer who offers water bottles and snack boxes, for example.

The two commodities are bought from different vendors and have different lead times. The snack boxes take four days to arrive (lead time = four days) and the water bottles take one day to arrive (lead time = one day).

You sell 5 water bottles and 10 snack boxes on a regular day. Your ROP with the vendor who distributes the water bottles should be ROP = 5 x 1 = 5 bottles if you don't have any safety stock. When you just have 5 bottles left, you have one more day of sales before you run out. Because you have a one-day lead time, the new supply should arrive just in time for you to keep selling without interruption.

In the same way, your ROP (reorder point) with the snack box seller should be ROP = 4 x 10 = 40 boxes. When you have 40 boxes of stock left in your inventory, or four days of supply, you should reorder. Given your four-day lead time, the new supply should arrive just in time, allowing you to resume selling without being interrupted.

For good inventory management, a reorder point is essential. Ensuring that sufficient product is constantly accessible in your inventory, lowers holding costs and eliminates stockouts, overstocking, and lost sales.

Instead of Excel spreadsheets, distribution centers and warehouses focused on expansion, scalability, and efficiency utilize inventory management systems and warehouse management systems (WMS). These systems take manual operations that are prone to human mistakes or oversight and automate them. One key procedure that may be automated with the correct software is inventory ordering. Reorder point, for example, is only helpful if firms use them.

If your company knows how many keyboards it needs to reorder, but there's no way to notify employees when there are only 50 left, you're back to square one: hastily calling your supplier when you realize you're out of stock. One of the most significant issues with figuring in reorder point calculator Excel files is this. Before the ordering point can be calculated, someone must export up-to-date data. This is a phrase that is likely to be forgotten when the warehouse is busy, and hectic periods are when firms require the most inventory control.

👉 Read More: Cash Conversion Cycle Problems And Solutions

A WMS, on the contrary, can alert a supervisor or management when a product's reorder level has been reached. Furthermore, when a product reaches the reorder level, warehouse managers can arrange their software to submit a purchase order to suppliers immediately, bypassing the notice and approval process.

One of the most extensively used inventory control strategies is the reorder point. Based on a target re-supply time and required safety margin, it estimates how much stock to order. Establishing reorder point frees up the valuable money and ensures that your inbound and outbound operations are running at optimal efficiency.

The most critical, and sometimes most difficult, aspect of effectively calculating reorder points is having trustworthy data for supply chain planning and delivering an accurate picture of customer demand.

The calculation will be erroneous if the data is incorrect, and you may wind up with too much or too little stock. If you need assistance in calculating your reorder point, you can use the formula provided above. In addition, this article also contains several useful techniques, which can be adjusted to the type of business you run. You've found this article so helpful? Do not forget to follow our Fanpage and website to get many interesting articles!