More Helpful Content

Having inventory ready for customers assists firms in meeting their consumers’ order demands. Suppliers generally categorize inventory based on its usage or priority, like cycle inventory, which is required for daily company operations.

Cycle inventory is one of the most significant inventory management approaches. It is the percentage of your inventory that will make or destroy your company, regardless of whether you employ the B2B or direct sales business model. Hence, it is essential to be able to manage and comprehend cycle inventory, which is one of the most important aspects of any business.

Cycle inventory, sometimes referred to as cycle stock or working inventory, is the portion of total inventory that is adequate to serve regular demand. It consists of the items that will be employed initially to fulfill client orders in a company’s regular business cycle. It includes products that are regularly sold and refilled in a continuous loop.

Cycle inventory is conceptually connected to safety stock since both of them are components of a business’s on-hand inventory, and the two terms are frequently used interchangeably. Cycle stock is also closely related to an organization’s inventory turnover rate.

👉 Read More: What Is Finished Goods Inventory? Example And Formula

The inventory cycle and warehouse management are inextricably linked. A warehouse manager’s major responsibility is to ensure the flow of items in and out of the warehouse. It means that knowing your company’s inventory cycle time is critical. It will enable you to reduce warehousing expenses while increasing the number of sellable goods. That is one of the explanations why it is essential to comprehend inventory cycle time.

A business cannot afford to buy a large amount of merchandise because the holding costs will be too expensive. Simultaneously, a business cannot afford to have little or no inventory because demand is very variable, and a shortage of storage might result in lost sales and consumers.

Therefore, cycle stock is kept in order to benefit from economies of scale and lower costs within a supply chain since its major function is to enable different stages of a supply chain to purchase merchandise in lot sizes that reduce the total of materials, purchasing, and storage costs.

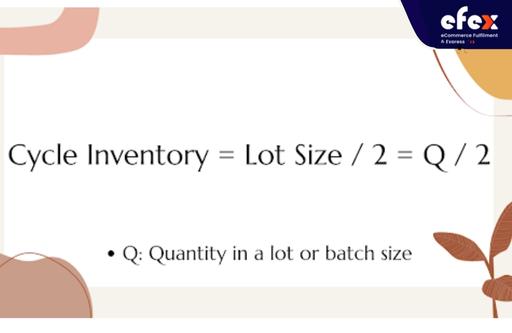

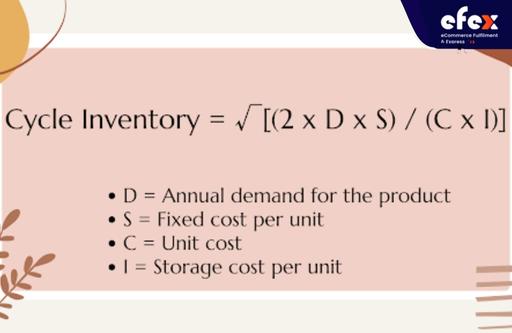

Cycle inventory refers to the average inventory in a supply chain as a result of either purchases or production in lot sizes bigger than those required by the buyers. It is calculated by using the below formula:

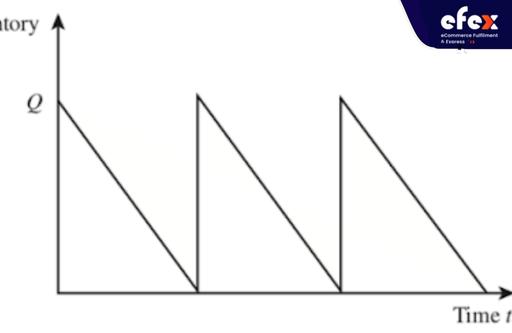

In this formula, Q is known as the quantity produced or purchased at a certain level of the supply chain at a given time. It is shown in the following graph:

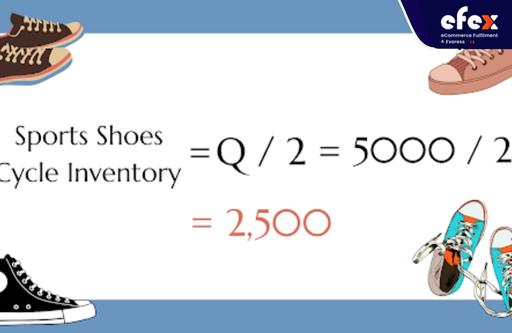

Assume the working inventory of sports shoes at a department shop that is Sports World Store.

At D = 500 pairs of sports shoes a day, with D is known as the demand per unit time. You can see that the demand for this pair of shoes is pretty consistent. The Sports World Store’s manager currently purchases in batches of 5,000 pairs.

Since purchases are made in batches of 5,000 units, and consumption is only D = 500 units each day, it will take 10 days to sell a complete lot. During these 10 days, the sports shoe inventory of the Sports World Store slowly drops from 5,000 units to 0 units, which are from the day the lot arrives until the last pair of shoes is sold.

This pattern of a lot arriving and demand decreasing inventory until another lot comes repeats, again and again, every 10 days. Since the demand is consistent, cycle inventory and lot size are connected in the following ways.

The Sports World Store has a cycling inventory of 2,500 pairs of shoes for a batch size of 5,000 units. According to the above formula, we have cycle inventory is proportional to batch size. Cycle stock is higher in a supply chain when stages create or acquire in bigger amounts than in a supply chain where stages generate and purchase in smaller numbers.

For instance, if another sports store buys 300 pairs of shoes in lot size, it will maintain a cycling inventory of just 150 pairs of shoes.

Cycle stock is the most essential portion of a company’s inventory since it is the items that are utilized to adapt to periodic sales and demand projections. To provide the best possible company performance, cycle inventory requirements must be forecasted. Cycle stock is also important to the company’s operations. This inventory creates cash flows, which the corporation subsequently utilizes to pay its creditors.

Furthermore, it is included on the balance sheet as part of the company’s total capital. The cycle inventory can be valued using the LIFO or FIFO approaches. The identical amount is subsequently entered into the balance sheet.

Businesses employ a precise formula to calculate how many items they have to purchase at once to keep production and cost-efficiency. There are numerous factors that the business needs to compute before applying this formula, including yearly demand or sales, costs of reordering, costs per unit, and costs of storage. After you have calculated these items, you may use this formula to determine how many units to order in one go.

A business’s goal should be to maintain the working inventory as low as feasible. It saves money by reducing shipping and storage expenses. However, savings must not come at the expense of missed sales. Therefore, a corporation must strike a balance in order to avoid losing sales and incurring excessive costs in keeping cycle inventory.

In practice, determining the quantity of working inventory may be difficult. It is due to the fact that it incorporates various variables like estimating demand, the time it takes to receive new inventory, and the inventory fill rate. Seasonality, demography, reordering costs, storage prices, supplier lead time, and other considerations are also considered.

👉 Read More: What Is Hedge Inventory? Example And Types

Overall, in order to calculate the cycle stock effectively, one needs to have a full grasp of the firm. When demand is high, a business must raise its cycle inventory to avoid stockouts. This might happen if the business does not have enough cycle inventory or safety stock. It might cost the organization money since it will lose sales and customers.

👉 Read More: What Is The Inventory Master File? Example File

Inventory cycle time is the frequency with which inventory is replaced. You can understand that it is the length of time it takes from the beginning to the end of inventory utilization.

In the retail industry, it is the time it takes for a product to arrive in your warehouse and be sold, which also refers to the time from the start of production to the finish of the manufacturing process. To understand easier, inventory cycle time is the time it takes for raw materials inventories to become completed items.

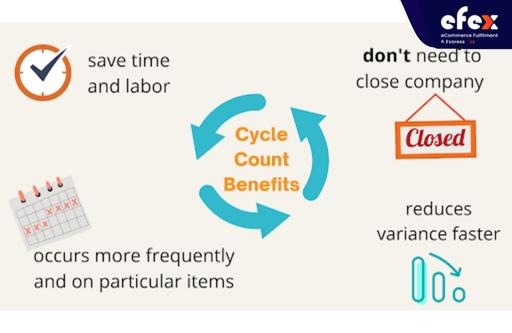

A cycle count is a type of inventory accounting for which just a fraction of the inventory is measured on any particular day. It is in comparison to a comprehensive audit, which counts every product in the inventory. A cycle count is a sampling method used to identify the accuracy of inventory data.

Cycle counting is the practice of obtaining sample inventories to cross-check inventory data in the inventory management process. Although it is not a perfect assessment of the whole inventory, cycle counts show any anomalies in product counts. This warns you of potential inventory concerns and indicates that a thorough inventory may be required.

Physical inventory is a manual count of every item in your inventory, whereas cycle counting is a considerably lower inventory count. Cycle counting provides numerous advantages over typical physical inventory counts. Below are the four key advantages of cycle counting.

Cycle stock management is essential to ensuring that the right items are monitored, therefore, no time or money is wasted. There are the greatest methods for ensuring that what you are doing is correct. Let’s check them below.

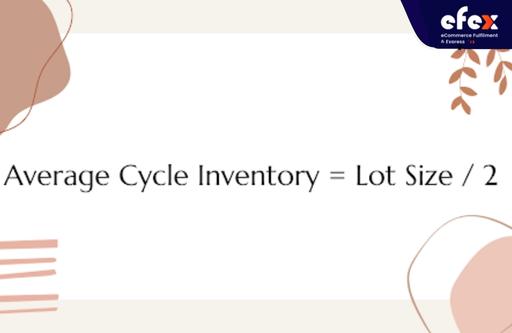

This is a simple calculation that is used to calculate your average cycle inventory. It will assist you in streamlining your business’s operations and avoiding cycle inventory difficulties.

Cycle inventory is an important component of total inventory. It is that portion of the inventory that enables the business to satisfy the product’s regular demand. Whether businesses resell products as merchants or manufacture products, it still plays an important role since this is the first thing a business does to fulfill a buyer’s request. Thus, well-managing cycle stock is an essential component of every well-functioning organization. Hope you have a good time with Efex.