More Helpful Content

Large format scanning is increasingly vital for architecture, engineering, and construction firms. While CAD software revolutionizes document management, older flat-file drawings pose a challenge. Many opt for a big format scanner, but choosing between CIS and CCD scanning is perplexing. Both have merits, but the decision hinges on application specifics. Continue reading to compare CCD and CIS scanning technologies and decide which is best for you.

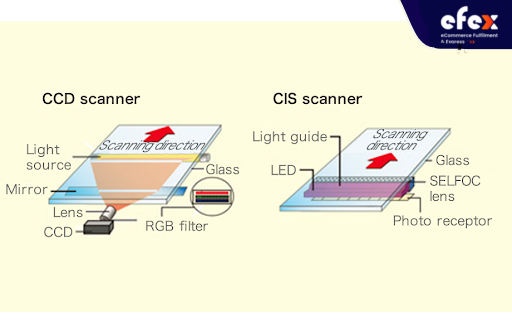

Charged Coupled Device is referred to as CCD. Essentially, CCD is the identical image sensor type that can be found in an older digital camera. To compress the entire picture onto the sensor, CCD utilizes a real lens.

This method is great for collecting details with a very high resolution and an enlarged color space. CCD scanners are frequently chosen when the best picture quality is crucial. The CCD scanner is the preferred scanner for greater resolution graphics as well as artistic applications due to its exquisite detail.

However, it is also typical to see CCD-type big format scanners being utilized for AEC or technical scanning. A deeper depth of field is an extra advantage of CCD scanning. If you want to scan several folded documents, this is useful. Fold lines can be somewhat reduced in appearance in the scanned file by employing CCD technology in the scanning application. “Mounted" or thick originals can also be digitalized using CCD scanners.

👉 Read More: Rfid In Warehouse Management System: Definition And Example

👉 Read More: Cube Utilization: Formula And Calculation

Here are 4 key advantages to thinking about a scanner employing CCD tech:

The CCD scanning technology offers high-quality scans for virtually all types of paper that may theoretically fit through the feed roll aperture. CCD scanning takes a grayscale of 16 bits from hand-drawn technical drawings, B&W pictures, or maps that are part of your original documents (64,000 shades of grey).

This method creates a picture that is significantly crisper and clearer by using a separate monochrome channel. In contrast, CIS scanners can only give a grayscale of 8-bit image (256 shades). There are certain restrictions on this, such as with full-bleed illustrations and instant copies printers with 8 to 12 colors.

The CCD scanning technology will provide you with a significantly more dynamic range in the unique circumstances of blueprints with rigid edges, scanning GIS, newspapers, delicate papers, or mylar film, and is thus strongly advised.

CCD scanners snap pictures of originals that are placed face down. This is because the image sensors are positioned below the scanning face. Some claim that the feature of facing up scanning enables greater quality control, but user education is really the key.

The majority of CIS scanners are designed to scan face-up; however, a face-down scan is neither more difficult nor less precise. CCD scanners have the capability of file transmission. These CCDs can make use of USB 3.0's full file-transfer capabilities. This ensures that users wait essentially instantaneously for file transfers between pictures. It follows that CCD is a superior option if overall speed is what you're looking for.

Due to the inherent technological advantage of camera-based innovation, the color gamut becomes noticeably bigger, color fidelity is greater, and image noise is reduced. Since cameras can capture up to 48-bit color, copying and printing to 8 or 12-color printers provide considerably better results than CIS. The intensity and the ability to identify fine gradients are better with CCD scanners.

CCD scanning technology is able to scan mounted original series up to 0.60" thick, whereas (most) CIS cannot. The CIS technology's optics do not effectively picture elevated or uneven surfaces, which is the cause of this. The CIS fiber optic lens array does not offer a significant depth of field.

Therefore, a CIS scan will show little features like fold marks. For best results, take into account a CCD scanner if your papers have wavy surfaces, like folded printouts.

The alternative scanning technology is called a Contact Imaging Sensor (or CIS). CIS technology utilizes several fiber optic lenses to transmit the original picture information to a variety of sensors as opposed to utilizing a regular lens to enlarge the initial image onto the sensor.

Although CIS scanning technology is less costly than conventional CCD versions, there may be significant picture quality trade-offs, especially when scanning aerial photographs or maps. The maintenance required for a CIS system is significantly lower since there are no cameras to calibrate and the sensors are managed by software.

👉 Read More: All Cost To Rent A Warehouse

Very little energy is used by CMOS sensors. They are excellent options for hand-held cameras because of this. However, CCDs use a lot more power yet create excellent photos. The power trade-off is irrelevant for CCD large-format scanners because they are stationary machines. In general, high-quality picture environments tend to yield superior results from CCDs.

As a result, rather than switching to a CMOS sensor, scanner makers have stuck with their current technology.

If you deal with CAD or GIS graphics and wish to convert them to a digital format, you should give CIS some thought. It is unquestionably the more economical option, and the gap between CIS vs CCD scanning has shrunk thanks to new, potent software programs. However, you should really consider a CCD scanning tech if your quality needs are more stringent, such as with fine art or photographs. You will receive the most excellent image quality possible. Yes, the initial investment will be significantly more, but it will be well worth it in the long term. Hope you have a good time with Efex.