More Helpful Content

While RFID has been present since the mid-1940s, logistics managers have just lately begun to use this technology for warehouse management. That has altered considerably in the decade after RFID made its first debut. Since then, RFID has become one of the most essential instruments in the supply chain manager’s toolkit. RFID usage and advancements in associated technologies have made it a far more reasonable and cost-effective choice for warehouses wanting to improve inventory management and operations.

If you are considering whether to use RIFD in the warehouse management system, let’s spend some time reading this article to understand this technology.

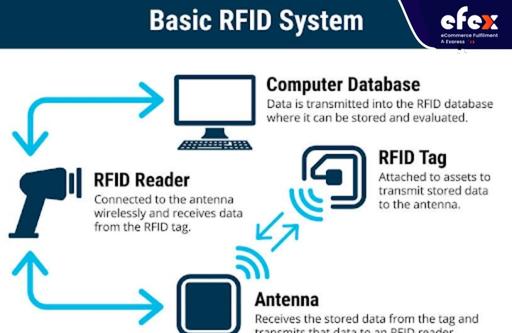

RFID which is the abbreviation of radio frequency identification is a radio-wave-controlled technology. Individual RFID tags may connect with reader devices even when they are not in a direct line of sight. The data may then be shared with software, such as warehouse management systems through the reader.

An RFID tag is typically made up of a microchip connected to a radio antenna installed on a substrate. This technology links items to the Internet for tracking and sharing data with companies along the supply chain.

👉 Read More: What is Pick to Box? How to use it effectively

👉 Read More: Cis Vs Ccd Scanning Technology: Definition And Benefits

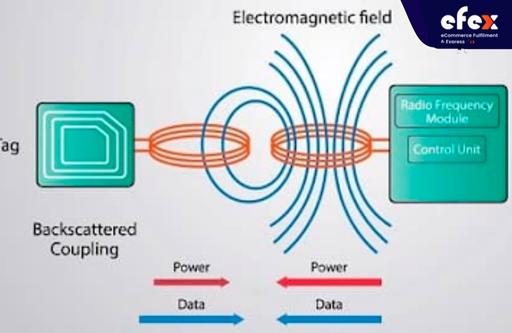

RFID systems are classified into two types which are active and passive. Active RFID tags are commonly utilized for big assets such as train carriages, containers, and cargo containers carried over long distances. Passive RFID tags lack transmitters and just reflect radio waves generated by the reader antenna. RFID transponders which refer to a microchip with an antenna are placed on items, and the information is accessible via a reader to be passed to a computer. Passive RFID tags are cheaper than active RFID tags because they lack power sources and transmitters.

In an RFID-based asset monitoring and management solution, every asset to be tracked is connected with an RFID tag. RFID tags contain an electrical radio transmitter, a small batter, and an antenna in their thin, microchip-like construction. Similar to barcodes, they can be applied on any surface with a little glue. They can also connect to identification cards, persons, and agricultural animals. Each RFID tag is assigned a unique identification number (UIN). It transmits a radio signal with the UIN at the appropriate moment.

Therefore, a receiver device known as an RFID reader or scanner retrieves and updates the UIN of every tag in its range.

Understanding the benefits of RFID in warehouse inventory management is critical in deciding whether to implement this new technology.

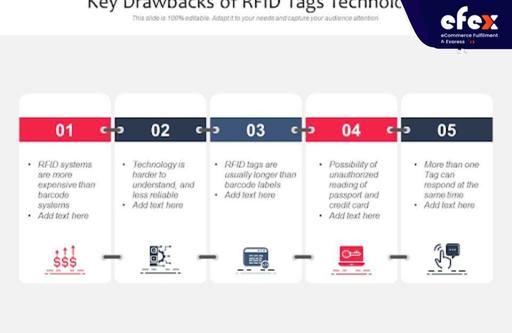

These tags offer various properties that make them ideal for inventory management problems. However, they do have certain downsides.

👉 Read More: All Cost To Rent A Warehouse

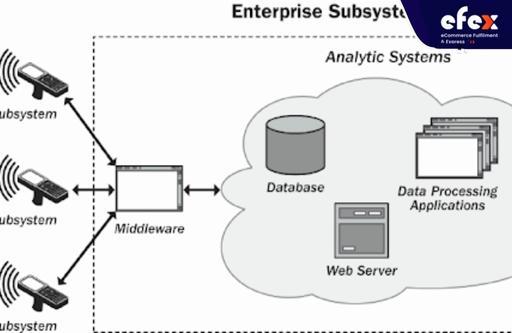

Inventory management and asset tracking systems are now built on a logistical mobility technology RFID subsystem that encompasses a broad range of application areas. An inventory management software is made up of many software components that work together to collect and process data, including UINs, from RFID tags.

Numerous RFID readers are deployed inside warehouses, transportation, and crucial sites linking them in a typical corporate configuration, including each entry and departure. The data collected by the readers is processed by the host computer before being sent to the database storage.

On the other hand, the database store is connected to the Rfid system, which includes the Entity framework and RFID reader API. The host computer may examine data from several readers at the same time. It analyzes the data and stores it in a buffer for a certain period of time.

RFID in the warehouse management systems is an effective real-time business solution that supports better management of supply chains, covers inventory entry, picking, inspection, delivery, and many different operation processes, and boosts profit while decreasing costs by enhancing visibility into the warehouse management system.