More Helpful Content

Undoubtedly, the consumer technology market is once again compelling industrial electronics producers to provide a similar service: the development of personalizing and customizable interfaces in consumer electronics is progressively pushing industrial electronics companies to offer a comparable service.

Now, how does this affect Original Equipment Manufacturers (OEMs)? It allows businesses to keep ahead of the competition and change their own production strategy before the competition does.

Configure to Order (CTO) production, also known as Postponement, enables OEMs to respond flexibly to unexpected or shifting customer demand. In this article, we'll define CTO and discuss its benefits in supply chain management.

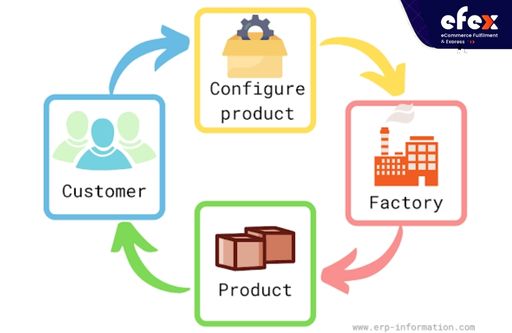

Configure to order (or CTO) refers to the manufacturing process of assembling as well as configuring products based on the requirements of customers. It also refers to a customer's capacity to specify the configuration of an item in real-time.

👉 Read More: What Is Fixed Manufacturing Overhead: Formula And Example

👉 Read More: What Is Manufacturing Overhead? Formula And Example

👉 Read More: What is part period balancing? Method and Example

In today's highly competitive market, companies who utilize CTO have a significant edge, given that more and more customers demand items that are personalized to their specific needs. CTO manufacturing is also an EMS supplier setting up a specialized factory line for your item, letting you to 'call off' customized and inspected units as needed, with a shorter lead time.

The procedure normally begins with the production of a sufficient number of 'base' units (also known as embryos), then they are kept in inventory till a customer order for such a top-level version is received. As once demand is received, the appropriate number of embryos are removed from inventory and configured to the final customer's wishes. This is especially useful when the OEM offers a variety of different types of products but cannot forecast which 'flavor' will be needed at any one time.

We'll utilize the ice cream analogy here. The van will be loaded with ice cream, cones, and a variety of toppings before starting its daily trip. Unluckily, they don't learn if their consumers prefer strawberry sauce, chocolate sauce, a flake, sprinkles, or a mix of all four until they start to play the melodic jingle. Before their customers arrive at the front of their van, they have no means of knowing with any degree of certainty what exactly they will want.

Sure, they can check back several weeks or even months to discover which toppings are much more preferred than others; however, that's all they can do. You can also practically bet that if they choose to discontinue offering a “slow-moving' topping, the next round of consumers will desire to order it. Does this sound familiar? The challenge is thus in building a strong supply chain that is capable of adapting to all potential combinations at a minute's notice while not spending more inventory than is truly required.

Configure to order is the foundation of the configure-to-order procedure. This means that when businesses use a work-in-process method (like CTO), their selections of designs are finished following the receipt of the work order. This is so because the process is built around predetermined customer criteria that are chosen from a list of established product features. Manufacturers utilize a combination of parts in the final assembly to produce a pre-established change or variant of a commodity in response to these consumer requirements.

The procedure is also a cross between “made to stock” and “made to order”. It is a collection of parts that are manufactured in bulk and manufactured to order. By keeping inventory there at the system level, inventory gets confined to only what is required. Besides, going to delay finished product assembling until the order comes also allows some freedom in terms of different products and helps to fully use existing component inventory. It assists businesses in lowering inventory carrying costs, facilitating inventory management systems as items are limited, and reducing time to market. As a result, configure-to-order is an effective business strategy that allows for bulk customization as well as faster order fulfillment.

Businesses employ the configure-to-order manufacturing technique to produce items specifically tailored to the needs of customers.

It has certain undeniable benefits for your supply chain. Here are several examples:

This is a significant advantage of configure-to-order. In order to meet the requirements of the customers, the customer gives a list of specifications that the manufacturer utilizes to create goods or obtain components.

The made-to-order technique eliminates the need to stock excess inventory that does not sell. This strategy only sells inventory that the customer needs. Storing and procuring inventory only once an order arrives relieves producers of financial stress caused by excess inventory. Alternatively, they might concentrate on adding more personalization.

When it comes to supply chain and inventory management, time is akin to money. Businesses will have a faster order-to-cash flow and lower cycle time to profit by offering customizable configure-to-order options.

The configure-to-order procedure manufactures products that are perfectly matched to customer specifications since it is completely adjustable. Customers are more satisfied as a result since products are delivered more quickly and there are fewer delays because producers already know the requirements.

Products are manufactured and configured on the sales floor depending on customer requirements with the management of CTO order which means they are basically built to order once buyer criteria are established. In the real world, instances of configuration items have included a car sales order (with all of its adjustments) or purchasing a pc over the web.

👉 Read More: Order Management System: Definition, Process And Value

👉 Read More: Order Management System For Ecommerce: Definition, Key Effect, Benefit

Any company strives for supply chain management effectiveness. Businesses can save a considerable amount of money and time by using a fully customized configure to order strategy rather than a one-size-fits-all strategy. Also, deliver the greatest customer service possible.