More Helpful Content

Although establishing an e-commerce warehouse for your e-commerce business does not necessitate high diplomas in logistics, it requires some forethought if you want your firm to function effectively.

That is why in this article, we want to assist you in preparing your warehouse for the changes. It is critical to not only have effective procedures in place to handle all sorts of requests but also to use the appropriate technology and infrastructure.

Below are the 12 top tips for e-commerce warehouse setup that you should not miss.

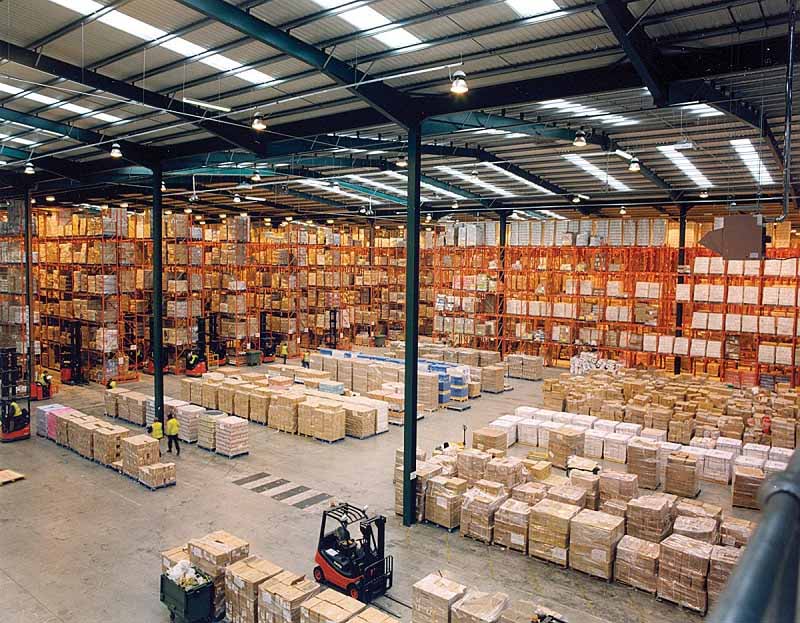

Calculate the amount of space needed by determining how many pallets or packing units you intend to store for yourself at any moment. Then double the result by the typical package, pallet, or carton’s footprint. Because storage and shelving solutions enable you to arrange your products and make the best use of the entire space, storage capacity should be assessed in terms of volume rather than area. You should take into consideration that you will also want some room in addition to the storage capacity.

Consider the space required for any additional warehouse operations as well as the mobility of the workers doing these tasks. Receiving and unloading items, quality testing, labeling, storing, forwarding staging, shipping, packing, mail processing, and some room for any type of inventory management equipment are all tasks that should be planned for when building a warehouse for your e-commerce firm.

Any warehouse’s basic aim is to optimize space, productivity, visibility, and safety. Based on your commodities, quantity, and company style, you will most necessitate various types of equipment. But, there are several necessities for your e-commerce warehouse. You will have to prepare storage equipment such as shelves, racks that are used in the warehouse, compact bins, or whatever relates to your specific product depending on your warehouse requirements.

You may also require specialized material handling equipment for transporting, loading, and storing. It is also critical to have adequate loading space for your warehouse business. It will make your employees more effective.

Besides, you should also keep in mind that your warehouse area is very well to optimize visibility and safety. Utilizing LED high bay lights may nearly totally illuminate your area, making all of your items visible and reducing the risk of any mishaps caused by low vision. LED bulbs should also be used to illuminate any workspaces, such as counters where your commodities are built, packed, or labeled for transportation.

Inventory management software as well as other technical equipment such as barcode scanners, printers, and your preferred e-commerce software are also available.

One of the most effective methods for the warehouse business to overcome e-commerce concerns is through technological innovation. However, many businesses are still apprehensive about investing in warehouse technology since it may be costly.

Buying a robot army comparable to those used by Amazon and FedEx is not essential when making preparations for your warehouse for e-commerce. Alternatively, you may begin with low-cost warehouse solutions like mobile printers that can print labels from anywhere in your warehouse. This type of equipment can cut warehouse staff’ traveling time and boost productivity and accuracy.

Furthermore, the usage of tablets and other handheld devices is growing trendy in warehouses since they help workers to stay connected regardless of their position within the facility. With the variety of warehouse technologies accessible in the present day, there is bound to be a warehouse solution that meets your requirements and budget.

👉 Read More: All Cost To Rent A Warehouse In 2023

Before the development of e-commerce, bulk orders were processed in distribution centers and warehouses. However, they are now working with smaller purchases and even single products, which necessitates a more effective selection method.

Cluster-picking is a simple approach to begin with if you wish to prepare your warehouse for e-commerce. It is a low-cost method that concentrates on choosing things rather than orders. To avoid mistakes, a single picker gathers many orders at once and arranges them in different totes. Cluster-picking reduces worker travel time, which speeds up the picking process and allows for shorter delivery schedules.

This process may also be enhanced by using a warehouse management system that gives the pickers an effective picking route and identifies the precise item to select and where to place it. This software may also prioritize item selection when one group of orders has to be prioritized above the others.

In the e-commerce world, a well-organized warehouse is crucial since the efficient organization makes warehouse procedures like selecting and restocking more accurate, simpler, and quicker. As a result, warehouse managers must understand the significance of slotting optimization in establishing their warehouses for e-commerce demands.

Warehouse slotting is the procedure of determining the best storage place for each item in your inventory. It enables warehouse staff to pick items more quickly, allowing for next-day or same-day shipping, which is a great suggestion in e-commerce. This form of e-commerce warehouse structure also guarantees that you are maximizing your warehouse storage capacity.

Manual warehouse slotting optimization is feasible. Although this method necessitates the examination of a large amount of data, which is at least a whole year’s amount, including seasonality and predicted inventory increase. As a result, putting money into a slotting optimization system to free up your time for other vital duties is a good idea.

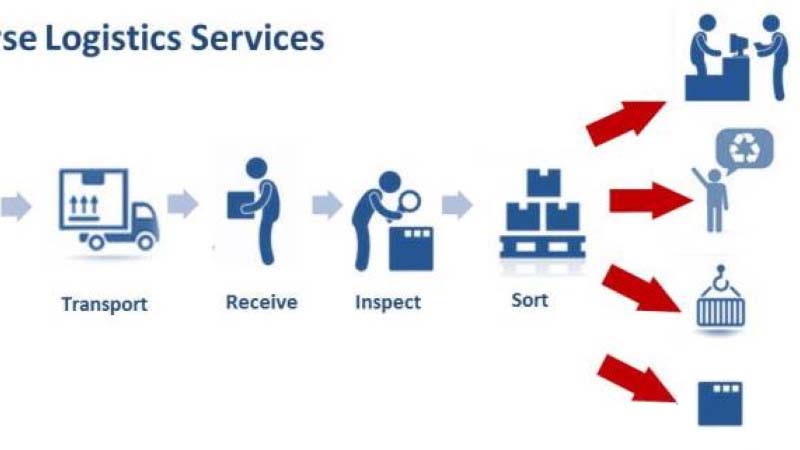

Earlier, many businesses were uninterested in improving their reverse logistics process. It has made it more challenging for them to handle returns in today’s e-commerce world, where delivering a hassle-free return experience is critical to customer loyalty. As a result, optimizing the reverse logistics process is critical. Among the strategies for optimizing this process, it contains designating a return area, establishing KPIs, and integrating warehouse technologies.

During this time, you should begin developing warehouse regulations and procedures for your employees. Pick pathways are only the beginning you must also consider safety protocols, workflow, and quality assurance correctness.

It is now the moment to put in writing the safety protocols that personnel must follow. We strongly advise obtaining OSHA’s Pocket Guide Worker Safety Series for warehouses and implementing its guidelines to the letter. However, don’t just stop with simply a brochure outlining your policies. Put them in place, then publicize them. For instance, you should post signage in strategic areas to urge employees to utilize appropriate safety equipment like gloves, hard hats, back braces, and other things.

In a perfect scenario, the actual system would be included in a single, well-documented workflow, from selection to packaging to shipping. Your setup will determine most of this procedure. However, a part of it will be dictated by warehouse regulations. For instance, how frequently do select waves occur? How much inventory must be moved to forward staging, and how frequently? When and where should equipment be stored? Consider the process from your employees’ perspectives, and then reduce any doubt they may have about any action.

Create quality assurance rules at each level of ordering.

You should create regulations for quality assurance and order accuracy early since these will be the foundation of your staff training.

You must teach your employees by providing them with the necessary abilities to do the duties they are required to complete properly. It will be a crucial component of your training when you have precise policies in place. A well-trained worker will save you money in the long term since any money invested in training your employees will be reflected in employee speed and productivity.

The correct warehouse management software can streamline your warehousing operations. There are several decent management software alternatives available, each with a distinct pricing point and giving a different set of features. This implies that if you are unhappy with your existing system and are looking for a warehouse management system replacement, there is almost certainly a WMS available that will meet your needs better. When making your decision, just consider the following basic operations:

The integration enables disparate business systems to effortlessly communicate data, bringing up a slew of options for cost savings, increased efficiency, and mistake reduction. So, what kind of systems must be integrated? Think about combining your warehouse management system with:

For successful implementation in your warehouse operations, you must be able to analyze your performances which are known as KPIs in order to determine if your warehouse is set up to run optimally. Creating KPIs will allow you to discover any flaws, process bottlenecks, advantages, and so on, allowing you to successfully plan your warehouse operation. Any decent warehouse management system would be able to readily track them.

You may set up as many KPIs depending on your needs, but the following are critical ones to measure for optimum warehouse management:

It is uncommon to set up an e-commerce warehouse arrangement that is flawless from the outset. Even if everything starts great, things can change. Because of new goods, new technology, and new business models, what succeeded earlier may no longer be optimum today. Note that when you make mistakes, you should learn from them.

To keep the ship operating smoothly, be responsive to change and accept new technology and business models. Learn from your mistakes and apply what you have learned in future practices. You should also learn from others by researching successful models and attempting to use their knowledge and experience to improve your own procedures.

👉 Read More: 3PL Warehouse Management System: Meaning And Benefits

Owning an effective e-commerce warehouse setup is important since setting up an effective and productive shipment and warehouse management system is critical for anybody launching an e-commerce firm. Because order correctness and delivery speed are crucial components by which a new buyer judges your service, how effectively you manage this influences customer happiness, shipping speeds, and the return rate. Furthermore, effective storage determines how much space you use.