More Helpful Content

A warehouse management system (WMS) is a software application that is used to monitor and regulate warehouse operations and commodities from the time they are accepted into the warehouse until they reach the end customer.

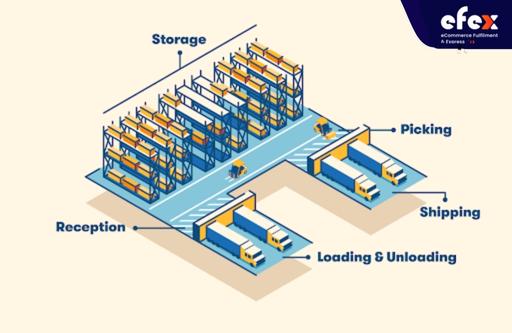

While a warehouse’s primary function is storage, a warehouse management system makes a big difference in ensuring that the commodities in the warehouse can be accounted for throughout the entire supply chain process. This enables data transparency in the administration of stock control. The top 10 Keys Functions Of Warehouse Management System are as follows.

One of the key purposes of a WMS is to effectively track the inventories that enter the warehouse and are then sent to their various locations of order. This feature provides the management with the appropriate insights to measure and know the availability of goods, as well as when the best time for restocking in the warehouse will be.

A warehouse management system allows warehouse managers to evaluate the demand versus the availability of their items so that they may restock inventory in the correct amount at the right time. This effectively eliminates supply scarcity issues, and it also eliminates the need for overstocking. Besides, it provides qualitative room for additional items to be stored in the warehouse.

👉 Read More: All Cost To Rent A Warehouse

A well-organized layout design is essential for a warehouse. a good warehouse floor layout will help you cut expenses and enhance efficiency in everything from production to assembly to order fulfillment and delivery. A WMS may help you build the optimal layout for your warehouse. A logical framework built into its system enables appropriate inventory placement inside the defined warehouse. The elements that determine the development of this systematic pattern design include accessibility, weight, and demand.

Another critical purpose of a WMS is to choose inventory and deliver it to the targeted customer base. With the presence of a manual system, missing data and ineffective tracking frequently confused missing or incorrect receiving and shipment of items.

On the other hand, you may have the advantage of tracking everything down and controlling it in your records with a WMS. It guarantees that orders are received by their respective proper clients within the time intervals specified. This also introduces fundamental retrieval methods, making the entire process much easier. There is no longer paying money on incorrect stocking of orders and delivering to mismatched clients, resulting in re-sending on carrying it appropriately.

More organizations are beginning to transition to a paperless warehouse system as a result of a combination of technical advancements, the need to reduce waste, general inefficiencies, and overall productivity. With WMS, there are no longer paper-heavy inventory recordkeeping days. It plays a role in reducing the requirement for paper-based paperwork. A WMS provides a unified picture of the complete inventory process. Its anywhere, anytime accessibility feature provides warehouse staff with the necessary data and information at their fingertips to accomplish their job.

Because a warehouse is controlled and supervised by a variable number of people, staff management is an important topic to discuss here. A warehouse management system (WMS) may look at and monitor the different performances displayed by warehouse workers as an enhanced technique for controlling warehouse operations. It has the potential to be a critical performance indicator, and its application in warehouse labor management can be beneficial.

Having real-time data regarding each employee’s productivity and effectiveness is critical for ensuring that operations are properly processed in the warehouse. Warehouse management also helps with staff management by making it easier for logistics and transportation companies to develop incentive plans that focus on increasing employee productivity and so effectively avoiding workforce burnout.

As a company grows in size, its product variety expands, as does the demand for greater warehouse space to store inventories. At this point, effective warehouse space management is crucial for organizations and is frequently the top focus of warehouse managers. While achieving this efficiency manually may appear intimidating, an automated WMS system is the only way to overcome these problems.

A solid WMS allows warehouse employees to store goods in the warehouse based on current demand and product weight. Keeping heavier items or those with a higher turnover rate closer to the door enables effective inventory management and saves workforce workers time and resources.

Another key role of WMS is to supervise order processing within the warehouse. A WMS aids in the accurate fulfillment of items and the timely delivery of products. The cost of wrong order stocking and distribution to mismatched clients is modest, lowering the overall cost of storage.

The strategic decision-making process of a company is built on data-driven and actionable insights. A warehouse management system gives broad and accurate insights into warehouse activities, aids in effectively monitoring merchandise in and out, and allows the warehouse management team to properly plan their future course of action. By utilizing the information collected in real-time from the WMS, warehouse managers get considerable power to drastically improve the business.

Customer satisfaction has always been the key emphasis of businesses. As a result, firms try to improve their processes in order to give their consumers seamless, tailored, and personalized experiences. A WMS facilitates the timely delivery of genuine items to the appropriate consumers. WMS is critical for ensuring customer satisfaction for existing consumers as well as obtaining and converting new prospects.

A good WMS has an audit trail that associates transactions with individual personnel. This promotes responsibility and opens the door to coaching based on individual performance objectives. A work management system creates a logical framework that is easy to follow and dramatically enhances the working life of your team. It creates clear KPIs and performance expectations for the warehouse workforce, promoting efficiency and accuracy.

👉 Read More: Top 12 Warehouse Management System Features

👉 Read More: Objectives Of Warehouse: Definition And How To Optimize

In conclusion, understanding these most important warehouse management functions is necessary. Since the warehouse management systems are so critical to the logistics and transportation industries, failing to integrate one would be a huge loss for your company. A sophisticated warehouse management system will undoubtedly increase your capital investment, but you are certainly making the ideal investment for your organization that will be responsible for increasing future ROIs.