More Helpful Content

Gross requirements refer to the total amount of a good or service required to satisfy demand from customers. It is crucial to comprehend and calculate "gross requirements" in order to make sure that your company has the inventory required to meet customer demand. In this article, we’re going to talk about gross requirements, why they are important, and how to calculate them.

Gross requirements refer to the total dependent and independent demand for a part before netting out existing inventory and planned receipts The gross requirement is the entire amount of raw materials, additional components, as well as subassemblies needed to make a certain item. It is a characteristic that both independent and dependent demands share in common.

It considers the availability of both independent and dependent needs. The manufacturing line moves processed or unprocessed goods in response to the dependent demand. Independent demands, on the other hand, are determined by elements in the external market, which determine what will happen to your finished products once you have accomplished all the steps necessary to produce them.

Prior to netting the available inventory or deducting the demands based on the anticipated receipts, we determine and establish the gross requirements. The bare minimum inventory needed to keep the business operating efficiently is known as the gross requirement. It does not take into account any predefined appraisal of scheduled transactions or the raw material availability in the inventory.

The overall input required by a thermal plant is referred to as its gross need. It will be measured by the thermal plant in tonnes of coal needed at the conclusion of each periodical productive cycle. For example, the overall sum of flour needed to make 40 slices of bread just for roadside food would be the gross requirement. Without taking into account, the aforementioned

The minimal number of materials needed to make a product is determined by the term "gross material requirements" (or GMR). The calculation takes into account the weight of the finished product, the raw materials, and any production-related waste. Manufacturers use the GMR calculation to make sure they have a sufficient quantity of raw materials available and to aid in planning for future production requirements.

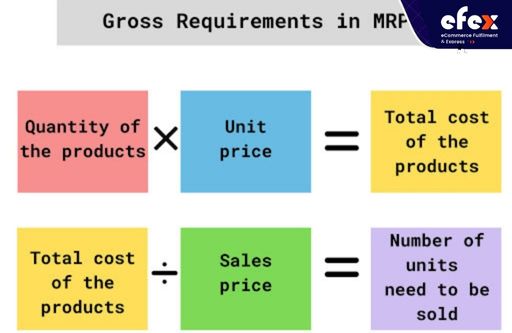

A product's quantity and unit price can be multiplied to determine gross requirements for MRP. This will show you how much the product will cost overall for a unit. The quantity of units that must be sold to recover costs is then calculated by dividing the gross requirement by the sale price.

Net requirements for a product are those determined by its gross requirements less any available stock and any scheduled receipts. A gross requirement is a strategy that displays the total demand for a particular item and also indicates when manufacturing should begin to meet its needs.

A net requirement plan accounts for on-hand inventory and scheduled receipt at each level. The majority of manufacturing sectors focus on managing the balance between gross and net requirements while also taking into account scheduled receipts as well as on-hand inventories. A thriving industry depends heavily on finding a balance.

👉 Read More: What Is SKU Rationalization? Process And Benefit

Before starting operations, a company must determine its gross need capacity. It is the number of raw materials necessary for the firm to operate at peak efficiency. The company can quickly decide the quantity of inventory that is currently on hand as well as other inventory levels based on increased demand using the gross amount required.

A business can reduce costs depending on storage if it has a clear understanding of the total amount needed to operate. This shows how much inventory must be on hand to prevent suffering a significant loss caused by a decrease in demand. Likewise, if a business is not adequately supplied for the future, it may lose consumers owing to a shortage of supply.

The planning functions of the MRP are where this calculation is first done. The MRP list is used in this computation to determine gross requirements by first identifying the demand amount for the item (where logistics will soon be scheduled) by time, and afterward combining them. Additionally, the period-unified gross requirements are carried over to the calculation of net requirements, when the allocation to inventories or released items is established.

👉 Read More: What Are Scheduled Receipts In MRP?

👉 Read More: What Is The Chase Production Strategy?

The full number of units that customers or retailers need is known as the gross requirements. Calculating the gross need involves adding the extra quantity required for backorders to the number of units that were sold. Businesses can utilize gross requirements to gauge demand forecasts and take both the present-day and anticipated future needs of their existing inventory inventories into account. Hope you have a good time with Efex.