More Helpful Content

You might believe that as a business owner, winning over consumers and growing your clientele should be your top priorities. While your consumers are crucial to the success of your company, a limited focus on growing your product line can result in a flurry of SKUs and a jumble of inventory which actually hurts your bottom line. One of the best methods to edit your products is through SKU rationalization. By reducing your inventory and order processes, you will potentially grow your business and prevent terrible stockouts. This article delves deeply into SKU rationalization and discusses its advantages and best practices.

SKU rationalization can be defined as the process of finding out which products to add, store, or cut from the merchandise inventory. This type of decision-making is mostly influenced by the types of products that are profitable and in high demand. There may be special reasons, nevertheless, why a business keeps less profitable products on hand. SKU rationalization demands a significant time commitment, access to pertinent data, and readiness for important decisions. Everyone participating in such inventory changes should be very aware of the advantages and disadvantages of their company.

- Read More: Order Management System: Definition, Process And Value

- Read More: Order Management System For Ecommerce: Definition, Key Effect, Benefit

If you offer on an online marketplace where success depends on a high order volume, SKU code reduction is even more crucial. Moreover, this is a technique for managing cross-functional inventory that aims to increase profitability. Days inventory outstanding (or DIO), or how long you retain inventory before selling it, is directly impacted by changes to the product catalog and SKUs. Your carrying cost increases when you keep merchandise on hand for a longer period of time.

However, be aware that SKU and UPC are not the same things. UPCs are universally uniform codes that monitor products as they move through various sales channels, whereas SKUs are specific product identification for your company. Companies can feel good about their progress when they use SKU rationalization. Making time to concentrate on your personal inventory requirements can support the success and profit growth of your company.

SKU simplification is crucial for all companies that sell many products. The importance of this activity, however, is greatest for companies that sell products that are susceptible to oblivion, like apparel or gadgets. For instance, a retailer of consumer electronics must routinely finish the SKU rationalization process to get rid of cellphones, gaming consoles, PCs, and tablets that are out of date and no longer in demand by customers.

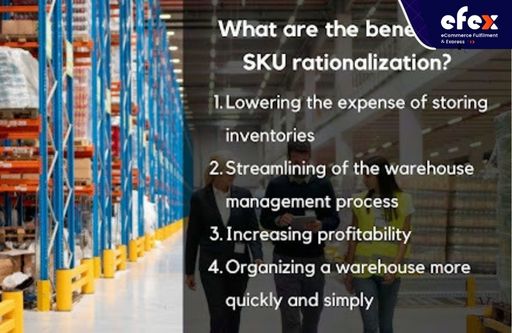

SKU rationalization is a true review of your product variety that advances your business, not simply some glitzy number crunching. Reviewing some of the advantages of SKU rationalization is helpful if a new company process is making you or your team nervous. To discuss with your team, these are the top four advantages of SKU rationalization:

You lose money for each product unit that is transported into your warehouse but isn't sold. Products are more prone to spoiling, breaking, or going out of date the longer they remain unsold inside your warehouse. Regular SKU rationalization maintains your profits flowing while supporting inventory reduction strategies.

Sometimes it could be impossible to prevent having a few cartons of disorganized goods. Nevertheless, if you have multiple boxes taking up unnecessary space, this interferes with daily productivity. Although the warehousing process flow shows where each pallet should go, the demands of your company could alter over time. You can also greatly simplify the work of your warehouse personnel by compiling a list only for important SKUs.

Making extra money is one of the biggest advantages of SKU simplification. You can scale more quickly by just keeping the goods that promote business expansion. In-depth SKU reduction also shows purchasing patterns, allowing you to carry more of the goods that customers want. As a result, your most lucrative products experience a rapid rise as well as brand relevance.

There seem not too many warehouse labels when there is less merchandise. As a result, fewer funds are spent on printing services, labels, as well as ink. SKU rationalization reduces expenses across the board for your company, from purchasing raw materials to handling and shipping.

The examples below demonstrate tried-and-true strategies for lowering your inventory management expenses and the quantity of discounted goods you sell.

Your sales data is likely the most crucial information to examine when you're trying to rationalize your SKUs. Products that remain on the shelf for an excessive amount of time or that sell in little quantities may be discarded. These products might frequently cost you more to purchase than they are worth in terms of revenue. Attempt to identify and phase out of production the products that cost your business more than in inventory management costs than they generate in revenue.

After completing the SKU reduction process, there are possibly a few items that you have determined not to manufacture or stock any longer. To quickly move these out-of-production items off the shelves, you might offer discounts on them. When you lower the price of an item, it will likely sell rapidly and you'll make money right away. You may lower your overhead expenses and ensure that these discarded items are removed from your storage as soon as possible by making sure they sell rapidly.

- Read More: What Is Available To Promise Inventory? Example and Calculation

- Read More: What Are Scheduled Receipts In MRP?

- Read More: How To Reduce Bullwhip Effect? 10 Tips To Minimize

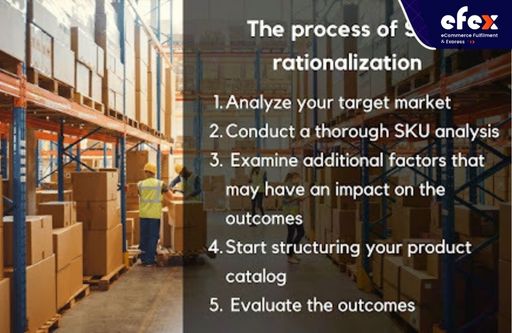

Reviewing your company's target market and differentiators should come first before you analyze any data. All of the items you sell as a merchant should be in line with this core value proposition because this will help you put together a range of offerings that appeal to your target market. Consider the following issues:

If your goods fit these criteria, it might be easier to understand why some SKUs aren't doing well. You can choose which items should be put forward for elimination from your inventory by creating a thorough list of potential products.

You likely already have a solid sense of which SKUs are doing well and generate a significant profit after accounting for stock and supplier costs if you routinely analyze your sales data. Even so, it's crucial to use the following examples for each of your SKUs:

You can identify all the various ways that an SKU can be hurting your business by evaluating these characteristics. Consider deleting a certain SKU from your inventory if it shows 2 or more of the given features. For easier inventory management, it's worth looking into possible solutions if an SKU contains one of these.

After conducting your investigation, it's critical to take into account any potential influences on the profitability of your SKU. For instance, a comparison of the outcomes with your marketing efforts over the same time period will demonstrate if any promotions caused the sales of specific SKUs to artificially increase. On the other hand, if you just released a new item that is identical to an existing one, the sales of the former may suffer. The term "product cannibalization" applies to this. Consider reviewing your offerings as well.

As you begin sorting, it's a good idea to divide up your SKUs into several categories so that you can evaluate them as you go. For the SKUs that you're unsure of, you may create columns for "keep," "delete," and "review." This will make your audit more understandable and help you avoid mistakes.

After the creation of your new catalog, it is crucial to evaluate the outcomes of the rationalization to determine if your operating costs have decreased or your dead stock has decreased. If this does occur without having an impact on your sales, it's a good indication that you were successful in efficiently optimizing your inventory. An audit should be performed every 6 months to maintain your home in good condition while giving you time to collect data for insightful analysis.

SKU rationalization requires time and effort, therefore it only makes perfect sense to maximize its benefits. It's even more important to complete an SKU rationalization properly the first time if you've never done one before.

Here are five best practices for SKU rationalization:

Making time for SKU rationalization is the greatest method to take advantage of it. Schedule a portion of a workday to measure your SKUs as you schedule days for inventory cycle counts and ABC analyses. You can possibly find that you possess less or more than you initially thought. Your employees will not only already be thinking about inventory optimization, but they will also be able to apply the information immediately.

Offering new products is thrilling, but it doesn't make much sense if your marketing strategies don't integrate them. Selling things effectively without experiencing stockouts should be a major corporate priority. As a result, your sales and marketing departments should communicate with your warehousing and forecasting employees. In this way, teams who are closer to the source of the product progressively support teams that serve more customers.

Promoting more efficiently than your rivals is a necessary component of corporate success. You can identify buyer gaps throughout your digital catalog by analyzing which items you sell and which ones you don't. If your company has a chance to surpass a direct rival but lacks a certain item, start including it in your short-term objectives. Your bottom line will increase in direct proportion to the added value you can provide to buyers that other firms cannot.

It's tempting to put everything into action immediately away once you've distinguished between profitable and loss-producing products. However, it's advisable to introduce changes gradually unless you have concrete sales statistics to support your decisions. Your forecasts' accuracy or need for revision will be shown in real-time by gradual changes to product availability.

Four objectives may be distilled into all business: sell excellent goods or services, be successful, be relevant, and enjoy yourself while doing it. Three of these involve SKU rationalization, therefore you should absolutely take advantage of it. SKU rationalization is mostly used for inventory maintenance; however, it has far more applications than that.

We've discussed how SKU rationalization can improve your inventory control and boost the profitability of your SKUs in this post. As an experienced 3PL company, Efex can help you with your SKU evaluation and make sure that your company is reducing its inventory in the appropriate places.