More Helpful Content

You can determine how fast a business can transfer its inventory into money by measuring the days in inventory. Knowing how to compute days in inventory will provide you with the necessary abilities to thrive in the finance and accounting sectors, including formula knowledge and the ability to interpret data. This article examines inventory days of supply calculation and explains to you the days of supply calculation.

Inventory Days of Supply indicate the average amount of time needed for your business to buy goods and sell them to consumers.

If you are a manufacturer, this indicator calculates the average period of time between the procurement of raw materials and the selling of the final goods to a distributor. Some businesses refer to it as inventory days of supply or days inventory outstanding. Knowing a business's days in inventory will help you determine how effective it is financially and operationally since it demonstrates how quickly a business can sell its goods.

A low number of days in inventory might be a sign that a business is efficiently running and promptly swapping its products for money. When a business experiences slow sales conversion, this might highlight the areas that may require more support, such as brand image development or revision or industry change adaptation.

In addition to this indicator, a business's management team must evaluate many aspects of its inventory strategy, including lead times, bulk discounts, alternative usage for warehouses, seasonal variations in order volume, and the chance that the inventory will become outdated.

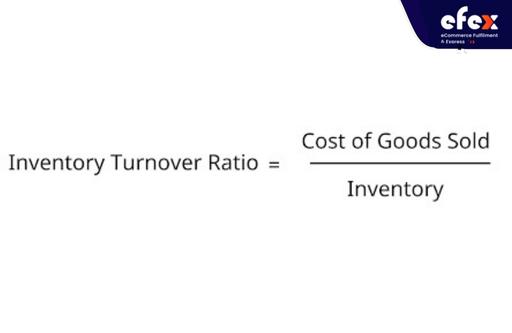

Any goods that a business sells and afterward replaces are referred to as inventory turnover. The turnover ratio assesses the effectiveness of a company's inventory sales. A business selling its products quickly and a market need for its goods are both indicated by a rapid inventory turnover. Using the following formula, you can get the inventory ratio value:

Inventory Turnover Ratio = Cost of Goods Sold / Inventory

The following formula can be used to determine days in inventory:

You need the following information to compute days in inventory:

You can determine the average inventory by calculating the average between the levels of inventory at the start and end of an accounting period. The entire cost of products sold in a given year may then be divided by 365 days to determine the COGS. On the other hand, the inventory turnover ratio is divided by 365 to produce the average times to transfer the inventory indicator.

Inventory Days of Supply = (The average inventory/ COGS)*365

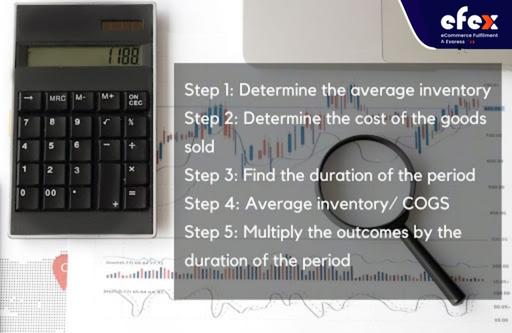

Here are the procedures to estimate days in inventory:

Find the company's average inventory if you want to determine days in inventory. Add the quantity of units that a company possesses at the time of its launch to the quantity of units at the conclusion of the period to determine the average inventory.

Next, divide that result by two to determine the average. Pet Stuff's average inventory, for instance, is $8,000 if they start the year with $10,000 in inventory and conclude it with $6,000 in inventory.

Add the cost of inventory held at the start of the period to the value of products to get the cost of goods sold. This can cover the price of supplies, labor, and any other expenses incurred by the business while producing its products. The value of inventory kept at the conclusion of the measurement period should then be subtracted.

In the Pet Stuff example, if the business has a $3,000 cost of goods, the computation may be written as ($10,000 + $3,000) - $6,000. So, $7,000 is the cost of the products sold.

Select the time frame for which you want to determine the number of days in inventory. Any period you choose to assess should have a length expressed as a number of days.

For instance, the duration of your period would be 61 if you were to think about the two months of February and March. Since the time in the example of Pet Stuff is one year, you should express this number as 365.

The first element of the two-step calculation for days in inventory is to divide the average inventory value by the cost of goods sold. This portion of the computation should divide $8,000, the average inventory, by $7,000, the COGS (Pet Stuff example). This produces a number that is rounded to the closest hundredth: 1.14.

By calculating the outcome of dividing the average inventory by the COGS by the number of days in the timeframe you're looking at, you can get the days in inventory. Given that the time frame for the Pet Stuff example is one year, you may multiply 365 by the 1.14 obtained in the previous step. As a result, the number of days in inventory for Pet Stuff is 416.1. Due to the high outcome, Pet Stuff may utilize the data to enhance its operations.

Here are 3 examples of days in inventory calculations:

Dental offices in the area can purchase supplies from Smiley Dental Suppliers. The company's cost of goods sold for the year is $50,000, and its average inventory is $1,000. What is the outcome of its days in inventory over a year? You can calculate the days in inventory using the given formula: ($1,000 / $50,000) x 365. The outcome is that there are 7.3 days in inventory. This low outcome demonstrates Smiley Dental Suppliers' effective market operation and positive financial management.

Frank's Repairs distributes replacement parts to mechanics and provides repair services. Its annual cost of goods sold is $65,000, and its average inventory is $4,000. What is the outcome of its days in inventory over a year? You can calculate the days in inventory by multiplying ($4,000 / $65,000) by 365. According to this calculation, Frank's Repairs has 22.5 days of inventory. The firm might interpret this as a low result, indicating that Frank's Repairs is managing and operating its money well.

For its small community, Green Grocery is a grocery shop that sells organic food items. The cost of products sold is $40,000 on average, while the average annual inventory is $6,000. How many days does the store's inventory spend on average over the course of a year? You can calculate the days in inventory by multiplying ($6,000 / $40,000) by 365.

The findings show that Green Grocery's days in inventory are 54.8. Managers at Green Grocery are aware that this duration in inventory could be high for a grocery shop and that they may modify their processes to be more productive financially and operationally.

Businesses can optimize inventory management, enhance cash flow, lower the risk of spoilage, and prepare for the future by calculating inventory days of supply. This calculation becomes routine practice as more companies use inventory management software to monitor inventory sales and turnover rates. You can track and control inventory levels and order handling with the aid of technology.

Besides, you can also quickly produce sales reports to determine how well you're operating your whole order fulfillment cycle. Businesses nowadays are well-equipped to maintain ideal inventory levels at all times thanks to solutions like these. Hope you have a good time with Efex.