More Helpful Content

A seamless supply chain and effective inventory management are critical. Retailers must guarantee that are correct items are available in the right quantities and at the right time. Poor inventory management may lead to a series of calamities, including unfilled or missing client orders and missed delivery dates. That is why using the right measurement is extremely important for merchants to guarantee that consumer orders do not take an abnormally long time to arrive. One of these metrics is the lead time in inventory management, which is critical in reordering planning and inventory management.

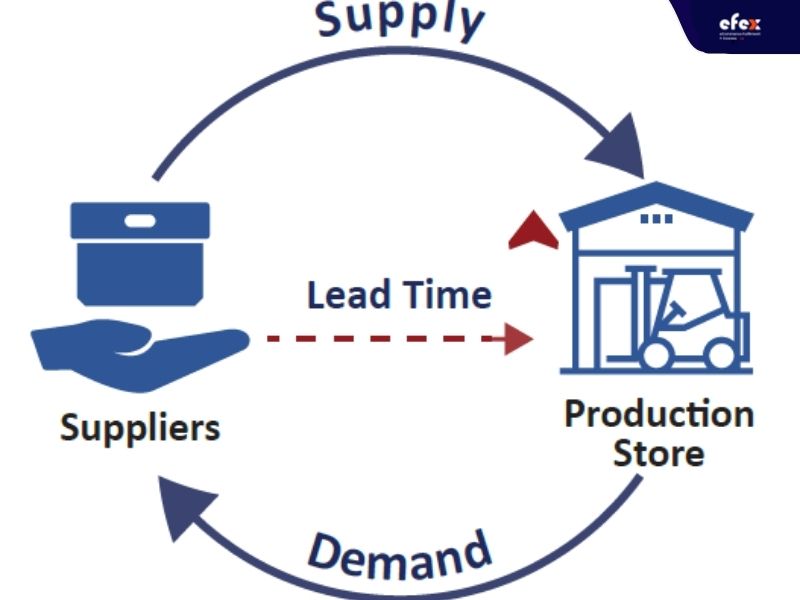

The phrase “lead time” can have several distinct connotations. It generally refers to the time between the start of a procedure and its finish. The lead time in inventory management is the time between placing an order to refill inventory and receiving the order. It comprises the acquisition and preparation of raw materials, the manufacturing from raw materials to the final products, and shipping.

When it comes to increasing production, revenue, and customer pleasure, any organization must examine an almost infinite number of elements. Everything from supply chain fluctuation to minor inventory loss issues can have an effect on your bottom line. To reach those objectives, you must constantly enhance your company’s efficiency.

One of the most significant methods to do is through calculating, measuring, and minimizing lead time. The lead time is the total of the supply and reordering delays. Order lead time might vary depending on the supplier. The more suppliers in the chain, the longer the lead time is. You must determine your reordering and supply delays. A supply delay refers to how long it takes for shipping to arrive at your warehouse, whereas a reordering delay means how long it takes for a supplier to accept and refill your order.

Lead Time = Supply Delay + Reordering Delay

Assume a supplier takes three days to physically deliver your purchase to you. But the day when you place your purchase might determine how long it takes to arrive. For example, if you make an order on a Tuesday, and your supplier only handles orders on Mondays, your reordering will be delayed by six days.

By using the lead time formula, it indicates your total lead time will be 9 days of lead time, which includes 3 days of supply delay plus 6 days of reordering delay. Lead time is commonly described in days, however, according to your suppliers’ timetables and how long it takes to get your purchases, weeks or months may be more suitable.

Lead time is essential in managing inventory and satisfying customers. If you have extended lead times, you must keep extra stock on hand to rapidly and thoroughly fulfill your clients’ orders. You must obviously pay for this storage, which results in increasing inventory costs and severe revenue losses. It can even impact your inventory at many points throughout the supply chain, not only what you physically keep in your warehouse or at your firm.

Furthermore, your lead times influence how adaptive and agile your company is. Once you have to expend resources in order to achieve and keep large quantities of things, you will not have as much space, time, or money to study new different products. You do not even have enough resources to upgrade your current goods and procedures.

Besides, people want online items to be delivered fast. 39% of surveyed customers say timely delivery is extremely important, while another 39% believe it is rather important. If it takes too long to deliver the product your clients purchased, they may not order from you again. Instead, they may order from one of your competitors. You must do all possible to retain clients and consistently enhance their experience with your company, which includes searching for new ways to reduce lead times.

Suppliers' inability to deliver a purchase order on schedule and in the exact amount might impair a company's production. It leaves companies with their existing on-hand stock which to fulfill orders. Buyers will face delays or fulfilled orders if these stockpiles are unable to react to customer demand until fresh supply arrives. The length of the lead time can affect the customer experience significantly.

Customers have a lot of opinions at their disposal now, and it is simple for them to take their custom elsewhere if they have a terrible experience with a merchant. When their orders are postponed or consumers cannot find what they are seeking, they prefer to look elsewhere.

While shipping and freight services have improved in recent years, there are additional elements that impact lead times. According to the Covid-19 pandemic, 68% of worldwide merchants suffered severe or medium supply chain interruption as a result of the disease's impacts.

Pandemics are not the only thing that may drastically disrupt the supply networks. Freight and shipment may be delayed which can cause supplies to be held up and can increase lead time. Border and customs authorities can intensify port checks, which leads to delays in the arrival of goods.

Besides, orders may take some time to review and authorize inside your company. Your suppliers will then need to place their orders for the materials needed to make your items. All of these elements add to the length of your lead time. However, after your supplier is acquainted with your orders and products, and you are more knowledgeable of the restrictions, the procedure should speed up.

When attempting to shorten lead time, the first step is to understand clearly your supply chain procedures from beginning to end. Track your supply chain trip and mark all locations along the road where you may anticipate waiting. Prepare for worst-case situations and seasonality. What would you do if your supplier is late right before a holiday sale? Once you have determined how long the probable lead time is, you may work backward to lessen it.

You can consult the following ways to shorten your lead times.

Rather than ordering a huge quantity of goods, order smaller quantities that will take less time to make and transport. Thus, your inventory is supplied more frequently and consistently.

Include a lead time clause in your supplier contracts. It may be in the bonus type if they produce ahead of schedule, or it could be in a penalty type if they are late. This aids in ensuring that your suppliers adhere to the agreement lead times.

Automating your inventory management operations may reduce your time to market. You can shorten the time it takes to produce and manage purchase orders, stay in touch with suppliers, and keep track of inventory levels all while avoiding human error and manual data entry.

It should go without saying that delivering your items from overseas vendors can lengthen your lead time. Finding international suppliers may sound appealing due to potentially lower manufacturing costs, but it may cost your firm more in the long term if you are merely waiting for goods to arrive. While finding local suppliers might considerably minimize your lead time.

There are some methods you can implement to improve lead times in your company. The following tactics can help you achieve this aim, but it is especially crucial to figure out what works best for your company.

Reduced lead time is one of the many reasons why you should use an accessible inventory management software system. By automating your inventory management operations, you can maintain supplier relationships, get orders to these suppliers faster, and share important information with your suppliers. It can also help you calculate lead times and keep track of your order and inventory data.

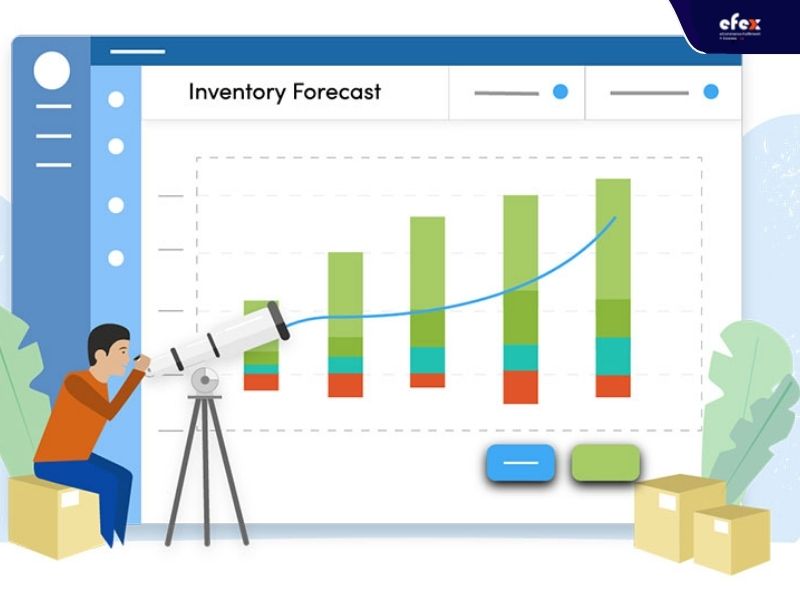

While forecasting demand accurately is essential for good inventory management, you can also share this data with your suppliers to optimize lead times. If they have insights into customer needs, they can better estimate your organization's demands and quicken the supply chain, particularly if you have a significant buy coming up.

Having a favorable connection with your suppliers is critical to reducing lead times, but if your suppliers often fail to deliver your orders on time, you can need to take further precautions. Consider offering a bonus or other incentives when they deliver your orders ahead of schedule, or a penalty when they are late. It may assist your vendors in adhering to the conditions you have previously agreed upon.

Kitting is the process of combining multiple supplies or product components that are often used together but are typically sold separately into a bundle or order. It may help you boost the efficiency of your orders. Your staff will spend less time looking for and organizing components, and you will be able to put away incoming shipments more rapidly.

Look for local suppliers or suppliers who are physically closer to your firm. It will take less time to send your orders when your suppliers are closer to you. Furthermore, if you move from foreign to domestic vendors, you will not need to worry about time differences affecting communications or customs delays delaying your transaction.

You may always change the frequency with which you place orders and the amount of stock you get with each order. Ordering in bulk may appear to be a straightforward approach to saving money on supplies, but if it affects lead times, it may cost you more in the long term. Comparing these expenses to see which option is less costly, and then experiment with order frequency and volume until you discover what is effective for your company.

Lead time is a crucial measure to evaluate since it can be used to estimate sales, increase customer happiness, and improve operational process efficiency. It can be difficult and frustrating to calculate and improve your lead times, but it is worthwhile. You can make a significant impact on your clients and your bottom line by concentrating on optimizing your lead time in inventory management.