More Helpful Content

Effective warehouse operations management can increase operational efficiency and reduce costs while promoting customer satisfaction. The main goal of warehouse operations is the efficient use of space, labor, and equipment to meet customer expectations. Although it is a simple goal, the path to achieving requires complex planning and the ability to adapt to ongoing change. How to manage a warehouse effectively with a proper method can be a challenge but you will get a lot of benefits by taking some very simple steps in your workflow. Here are some of the best ways to achieve more efficiently managed inventory.

Depending on the needs of your business, you should invest in a qualified and experienced warehouse manager. A manager with specialized expertise in the equipment and processes can keep your warehouse running efficiently. This person knows detailed information about the space, tools, and strengths of each employee they hire in the team.

In many cases, if something goes wrong, a professional manager will know how to fix the problem with little damage as possible. To help your business to be more efficient in the future, you should find an applier who knows which technologies are expected to give your business a Swiffer ROI.

👉 Read More: All Cost To Rent A Warehouse In 2023

Another way to improve overall inventory control is to help warehouse employees do their jobs more easily and efficiently. For example. you can set safety standards to protect your employees from potential hazards on the warehouse floor or adjust your cleaning schedules to a more optimal point, and build a detailed organizational plan so that employees easily locate products with large volumes. Use automation to maintain an accurate record of all warehouse operations that employees can briefly refer to on the announcement.

Whenever you deploy new technology, take time to hold required training sessions and familiarize all warehouse staff with the new software and systems. In this way, you give them additional opportunities to optimize daily inventory control. Employees who understand a warehouse inventory system will adhere to it better and operate the site more efficiently. If you have a knowledgeable staff, you can make sure that your workforce maintains a properly organized warehouse.

Warehouses must be designed, built, and arranged to meet the requirements of travel routes and emergency routes. There is a system equipped with fire prevention and fighting. Warehouse ceilings, walls, and roofs must be designed and built to ensure the ventilation and circulation of the air. Withstands weather impacts such as sunshine, rain, storm, flood…

The warehouse floor must be high enough, flat, smooth, strong enough, hard, and handled appropriately. Ensuring the operations of the staff in the warehouse and the movement of the vehicles. The warehouse floor must not have cracks or fractures ... is a place to accumulate dust, the shelter of pests and insects.

Example of drug storage: Storage area must be large enough, with separation between areas. Suitable for individual storage purposes of each drug.

Warehouses should be equipped with appropriate facilities and equipment to ensure storage conditions. For example ventilation fan, air conditioner, cargo truck, forklift, thermometer, hygrometer ... There are enough equipment, shelves, and shelves for storage, to avoid items that are easily damp on the warehouse floor. The distance between shelves, shelves, and the warehouse floor must be large enough to ensure warehouse cleaning, check, comparison, loading, and unloading of goods.

Having all necessary equipment and instructions for fire and explosion prevention and fighting. Required: automatic fire protection systems, fire extinguishers, sandboxes, water systems, and fire hydrants… Strict regulations on entry and exit of the warehouse. Allow only those with functions and duties to access and manage the warehouse. Product storage and preservation should be designed in accordance with the requirements of each commodity. Avoid the infestation of pests and pests.

It is essential to align your products so that your inventory managers can ensure efficient operation and manage your inventory. This rule not only applies to the general layout of your warehouse but also applies to your SKUs. Apply lean inventory methods to reduce inventory levels and assist employees to perform work effectively. High volume and fast transport SKUs should be located in easy-to-reach locations.

By prioritizing fast-moving warehouses, you can reduce the loading and unloading times of those products to manage a warehouse more efficiently. Do not place the best-selling items in the far area, instead of that, you should keep these items in an easy-to-see position.

It is obvious that there are different seasonal needs so you should have a careful plan that is suitable for you during these certain times of the year. Warehouse operating conditions rarely have static dynamics. The evolving nature of the supply chain management means that warehouse operations must be highly resilient to change.

Having a strategy carefully planned for each warehouse function, performing well on those strategies, and maintaining the flexibility needed to adapt to constant change are the hallmarks of operational management efficient warehouses.

The business needs to change over time. Check how it works annually, what updates are available and what might have been missing. Evaluates whether changes are needed to make it work more efficiently.

The bin location serves as a kind of geographic map of where all the warehouses are sorted. This is one way to divide up the segments in your inventory. Use them to manage everything most efficiently so employees quickly know where the product should be.

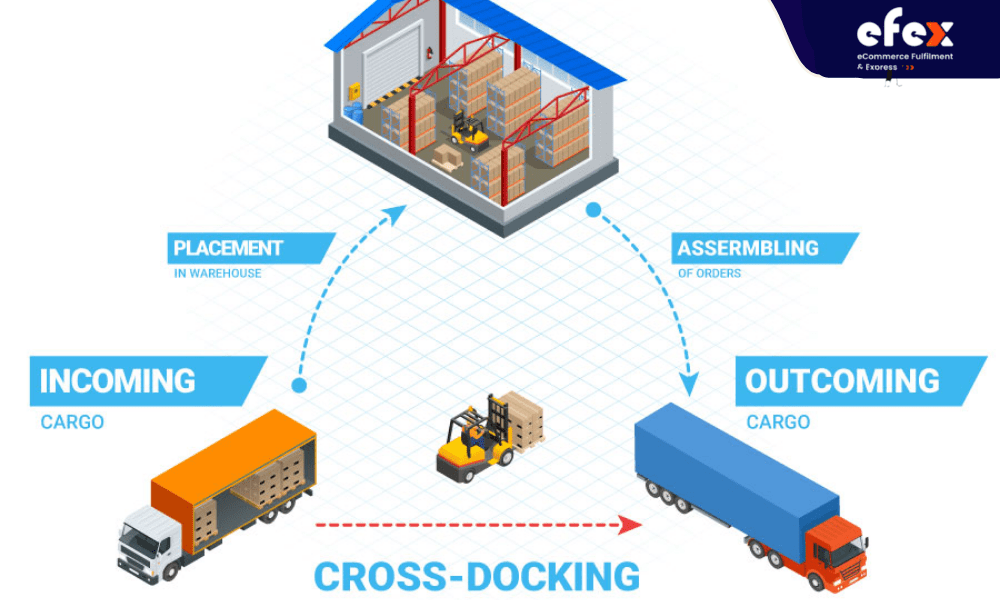

Cross-docking is considered a logistics technique. It is responsible for carrying out the functions of receiving and sending goods from the incoming trailers to the outgoing trailers without an intermediate storage area. The use of cross-docking helps reduce costs as well as increase the efficiency of exploiting or receiving stored goods and then immediately loaded onto trucks to transport them to specified places.

It can be said that a safer warehouse is also an efficient warehouse. Employees who know how to use the equipment correctly and safely often keep warehouses operating more efficiently and better managed. Likewise, make sure that hazardous areas are marked and safety protocol comes first in everyone’s mind. That is a perfect method of how to manage warehouse operations.

Using the technology in managing warehouses is a perfect choice, for example, warehouse management systems (WMS). It has advantages that include integrating systems and workflows, strategically organizing execution systems, increasing inventory visibility, minimizing risk from volatile demand, and more to secure the highest inventory management performance.

Personnel costs will be very expensive when there are a large number of items. Using warehouse management software will certainly minimize the number of employees. Facilitates human resource management easier for managers.

With the minimization of the number of employees, the budget for the maintenance and replacement of new equipment and tools to support and maintain the operation of the warehouse is also reduced significantly.

When using warehouse management technology, in addition to optimizing the inventory, and making the most of the storage space in the warehouse, these techniques also help businesses manage inventory in the most accurate way.

Always grasping the number of goods and the number of items will help businesses always provide customers with the products they want quickly and fully. Always manage your information in detail, and having a stock overview helps to minimize inventory.

For large enterprises, the task of managing goods in warehouses is always focused. Businesses often take a lot of effort into managing physical warehouses. Now just sitting in the office, the complete managers can control all the warehouses of the business through software manipulation. In addition, businesses completely analyze the flow of goods, and warehouse operations to make appropriate adjustments in the updating, and exporting of goods, and control the operations of the warehouse safely and clearly.

In smart warehouses, when used in conjunction with a handful of other key technologies, such as “asset tokens” and inventory, an automated inventory control platform is deployed to include elements such as labor, guesswork, and the timing factor away from traditional inventory control. To do that, most of these platforms are built to automatically count inventory and aggregate data for fast, real-time, and extremely accurate reporting that can be remotely accessed for tracking, control, and data extraction of a smart warehouse.

👉 Read More: 15 Most Importance Warehouse Management Best Practice

If you have a wonderful plan on how to manage a warehouse effectively, you and your employees will be endowed with security, growth, and long-term success that allow you to innovate well into the future. However, you can visit EFEX - a trusted fulfillment & express provider in Vietnam, which promisingly brings you the best solution to manage your warehouse effectively!