More Helpful Content

According to a Pitney Bowes study, global parcel shipping volumes surged by 150%, from 64 billion parcels in 2016 to 161 billion in 2022. With the projected global parcel volume expected to reach 225 billion by 2028, the demand for faster and more efficient picking processes is at an all-time high.

As a vital aspect of warehouse operations, picking now has become a significant challenge to fulfillment efficiency, especially with the rise of online shopping.

However, fulfilling individual orders can significantly slow down the picking process. To overcome this, many companies are adopting a method called fulfillment batching to accelerate the dispatch of orders to customers promptly

But what exactly is batching? Let's delve deeper, exploring how it operates, and its pros and cons.

A batch means a set of the same items that will be put into similar orders to different buyers.

Fulfillment batching, also known as batch picking, is the process of gathering multiple packaged orders that will be dispatched at the same time. That means a picker can collect items for multiple orders at once instead of picking items one by one.

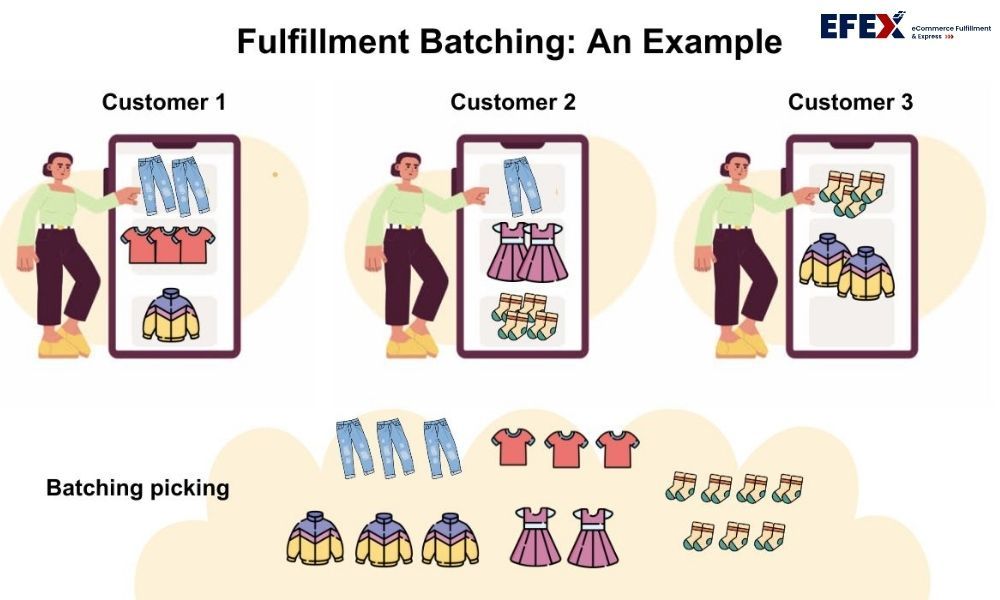

For easier understanding, let’s imagine you run an online fashion store, and you receive three customer orders as follows:

Instead of grabbing each customer's order one by one, a batch picker gathers all simultaneously including:

and place them in a designated container on a pushcart. Afterward, the pushcart is taken to the sorting area, where the items are efficiently sorted, arranged into individual orders, and readied for shipping.

Batching methods can speed up the picking and packing process, boost accuracy, and allow for cost-effective shipment. This eventually streamlines the whole fulfillment workflow and raises the customer experience.

Batching is especially advantageous when acquiring wholesale items and utilizing bulk shipping, both of which need a high order volume. It's also employed when the products that need picking are spread out in different sections of the warehouse or storage space.

>> Learn more:

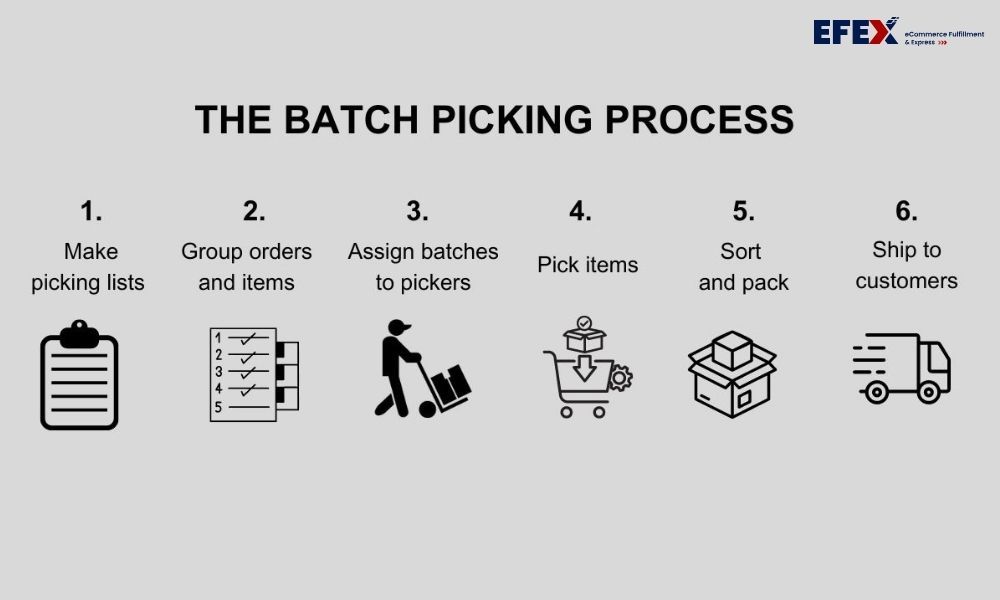

In a nutshell, the batching process involves picking items from a warehouse and placing them in boxes or bags, which then get sent to a shipping facility for dispatch.

Here are the details for each phase of batch fulfillment order management system:

A picking list is a document that guides the warehouse or fulfillment center team on the items to be picked to ship, including details like stock-keeping units (SKUs), quantities, and storage locations.

Batch picking works best when orders share identical lists, allowing pickers to efficiently complete multiple orders at once.

While picking lists can be manually created and checked for errors, the process is now mostly streamlined with a warehouse management system (WMS) and order management system (OMS) that can automatically batch similar orders. This simplifies picking, minimizes travel time, and enhances efficiency.

In modern practices, pickers often utilize wearable devices and speech technology to digitally organize, allocate, and fulfill each order.

Batching and picking are the processes of combining orders that include identical goods into a single picking batch. An OMS or WMS can accelerate the workflow by automatically collecting batchable orders that include the same products and quantities.

Pickers obtain their picking list and get the supplies required for fulfilling each order. As previously stated, a WMS can create new batch pick lists for every single picker, allowing them to gather goods timely and effectively.

When this process occurs manually, you must design an appropriate path for them so pickers can efficiently gather all of the SKUs required.

Each picker must carefully follow the provided picking list to ensure they pick the right items. This not only ensures accuracy but also helps them take the best route, saving time and avoiding unnecessary steps

The way of picking varies by the business needs. Some use carts with separate containers for each order, while others let workers collect directly into shipping boxes. Alternatively, similar items may be put together in a single bin, which goes to the packing team for sorting before shipping.

No matter the method is applied, the pickers go through their lists, focusing on one thing at a time. They often use handheld scanners to keep track of each item and their quantities.

Once all the items for a group of orders are collected (a batch), they go to the packing team.

If the initial picking process does not involve sorting and packing items into containers, the chosen items are directly sent to the staff responsible for sorting. These sorters then categorize the items into their designated orders, ensuring each order is correctly packed and ready for shipping.

Once the packing process is finished, the orders are ready for shipment. The shipping team takes over at this point, handling the logistics of getting the packages to their destinations, coordinating with carriers, and ensuring timely and accurate delivery to customers.

Fulfillment batching is a game changer for the picking process in e-commerce businesses. It has shown to be advantageous by increasing picking speed while simultaneously making warehouse operations more efficient.

Let's take a deeper look at the benefits!

Batch picking is one of the most highly efficient among picking methods that allows pickers to handle various orders at once. As pickers only collect the same items in each trip, it is easier for packers to sort and pack them for individual orders.

Moreover, with batch order fulfillment, pickers can get items for different customers without going back and forth in the warehouse multiple times. This not only speeds up packing but also simplifies it, as the packer can use the same box and packaging for a set of orders.

According to Amware Fulfillment, travel time is a big obstacle to efficient order picking, making up to 50% of the entire process and potentially half of the labor costs in a warehouse.

Without an optimized system-assisted picking process, the cost goes toward paying order pickers for walking rather than picking. Not to mention, large warehouses can take a long time for employees to move from one end to another

Luckily, the batch fulfillment approach helps by centralizing tasks, allowing employees to handle many similar tasks together and covering shorter distances each time.

Moreover, with carefully planned picking paths, pickers can also avoid unnecessary backtracking or repeating the same route multiple times in a single shift. This big cut in travel time significantly improves how quickly items are picked.

Ensuring your order fulfillment is fast and efficient is key to the success of your operations. When using the batch fulfillment method, warehouse staff won't need to cover the entire warehouse extensively, making their tasks quicker.

This reduces travel and time between orders, ultimately cutting down on the overall time needed to fulfill a standard order. Consequently, orders swiftly progress through the system and are prepared for delivery without extended waiting in the fulfillment queue.

Moreover, most modern warehouses nowadays are with modern advanced technologies. According to Logistics Management, there's a rise in technologies like RF-assisted scanning, up by 9% since 2017, and voice-assisted scanning, reaching a 12% adoption rate.

These technologies effectively minimize both mental and physical fatigue on the labor; and hence enhancing the overall efficiency of warehouse operations.

Not all businesses and distribution models easily fit with batch picking. It involves much planning, and if improperly carried out, it might lead to troubles later on.

Before adopting batch picking strategies, warehouse managers and business owners should consider the following possible challenges.

Batch picking is not the best choice when dealing with various customized orders.

Customized orders often involve unique items or specifications, while the nature of batch picking relies on grouping similar items together to fulfill multiple orders simultaneously.

Besides, handling customized orders individually requires a more tailored and accurate fulfillment process. Each order can be processed separately, ensuring that the unique items or specifications are correctly picked and packed according to the customer's specific request.

A typical example is the POD (Print on demand) T-shirt industry. The company needs to print T-shirt designs with customers' names or other special printing requirements. These products are unique and need to be picked, packed and shipped separately.

Therefore, using batch picking for customized orders can lead to inefficiencies and errors.

Batch picking relies on specialized software for efficient order grouping, optimized routes, real-time inventory management, and accurate order fulfillment.

This software integration ensures seamless operations, automates tasks like generating picking lists, and provides real-time monitoring for enhanced efficiency in batch picking processes.

Even a small error in order batching or mix-ups between customer orders within the same batch can lead to significant downstream issues.

Studies show an average picking error rate of 1% to 3%, which might seem acceptable. However, when considering the full cost of picking errors, with an average cost ranging from $50 to $300 per error, it translates to an 11-13% impact on profitability.

That's why fulfillment batching requires advanced software to ensure high accuracy and smooth subsequent processes.

Even though software plays a big role in batch picking, it still depends on human involvement in most cases. Errors can increase when multiple orders are filled simultaneously if the packing process lacks organization.

Furthermore, the software works well only when the staff using it is competent and familiar. Insufficient training or lack of familiarity with the software can lead to mistakes. Additionally, mistakes can also happen if employees are overworked or unhappy.

While software helps minimize errors, it's important to take a comprehensive approach. This means keeping data accurate, training staff regularly, ensuring smooth integration, addressing exceptions, and quickly resolving technical issues.

A delayed rollout in batching fulfillment can come from the intricacies involved in introducing new technologies, processes, and training methods, as well as the need for careful planning and risk management.

The process requires time to stabilize, potentially causing initial delays.

Are you a small business in need of a rental warehouse? Or are you seeking to outsource 3PL with expertise in batch fulfillment for the upcoming sales holiday?

EFEX stands out as the top robust solution to address the challenges of efficiently managing order fulfillment in peak seasons.

In the hustle of peak seasons, EFEX ensures multiple orders are processed at once, cutting fulfillment times and boosting overall efficiency.

Check out our features:

Say goodbye to the chaos of peak seasons! Now EFEX will become your secret weapon for your success!

Batch fulfillment is much like a game-changer for e-commerce businesses, boosting productivity and efficiency.

Any company can implement batch picking in their warehouse operations if they have enough resources and time. Alternatively, they can also hire an experienced 3PL like EFEX to smoothly handle this job.

By partnering with EFEX, you can further optimize your entire order fulfillment process and serve your customers more quickly while focusing on your core growth.

5 common order picking methods include:

Batch picking means gathering similar items for multiple orders at once, making things faster and reducing travel time.

Single order picking is about picking items for one order at a time, ensuring accuracy and flexibility, which works well for smaller or customized orders.

Batch picking involves collecting goods for multiple orders simultaneously, while zone picking assigns specific zones to individual pickers. This method streamline the process by having each picker responsible for a designated area in the warehouse.

Batch picking is more holistic, handling multiple orders at once, whereas zone picking is focused on keeping products organized in different parts of the warehouse.