More Helpful Content

About 70% of an order picker's time is spent on travel and searching for items. One of the highly effective ways to cut down on this time is by dividing a warehouse into different zones.

As a warehouse manager, understanding all aspects of zone picking is crucial to maximize its benefits. Look no further! This guide will offer a comprehensive overview of zone picking, covering what it is, how it works and its pros and cons.

Zone picking is an order-picking method in which pickers are assigned to choose and sort products from a dedicated zone within the warehouse.

In this process, the warehouse is divided into different zones or areas specified by product category, size, weight, SKU velocity, racking type, environmental factors, picking requirements, and other similiar characteristics.

No matter how these zones are established, each picker is responsible for picking items only from their assigned zone. Therefore, if an item is placed in a different zone, it will be assigned to another picker for selection.

Zone picking is frequently utilized in sizable warehouses or distribution centers with a wide range of products and a significant amount of SKUs to improve efficiency and reduce order fulfillment times.

👉 Read More: What Is Order Picking In Warehouse: Importance And Method

When an order comes in, instead of one person picking all the items, multiple pickers are assigned to different zones, each responsible for picking items only within their designated zone.

There are two primary types of zone picking: sequential and simultaneous, each works somewhat differently.

To illustrate the operational difference between sequential and simultaneous zone picking, let's give an example: a warehouse that stores various electronic products, such as smartphones, laptops, and accessories.

The warehouse is divided into three zones:

A customer's order includes a smartphone, a laptop, and an accessory. Let's see how these two zone-picking methods work!

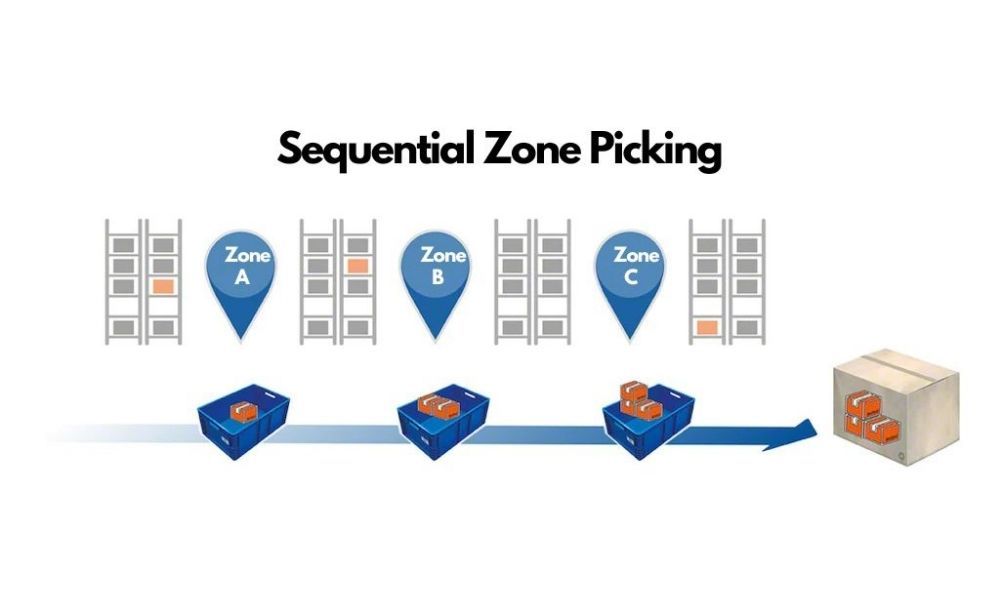

In this method, each order is processed sequentially through the zones of the warehouse. The order moves from one zone to the next, and each picker in each zone fulfills their part of the order before passing it along to the next zone.

In the above scenario, a picker in Zone A picks the smartphone first, then it moves to Zone B for the laptop, and finally to Zone C for the accessory.

Sequential zone picking is typically used for smaller orders or when there are strict deadlines.

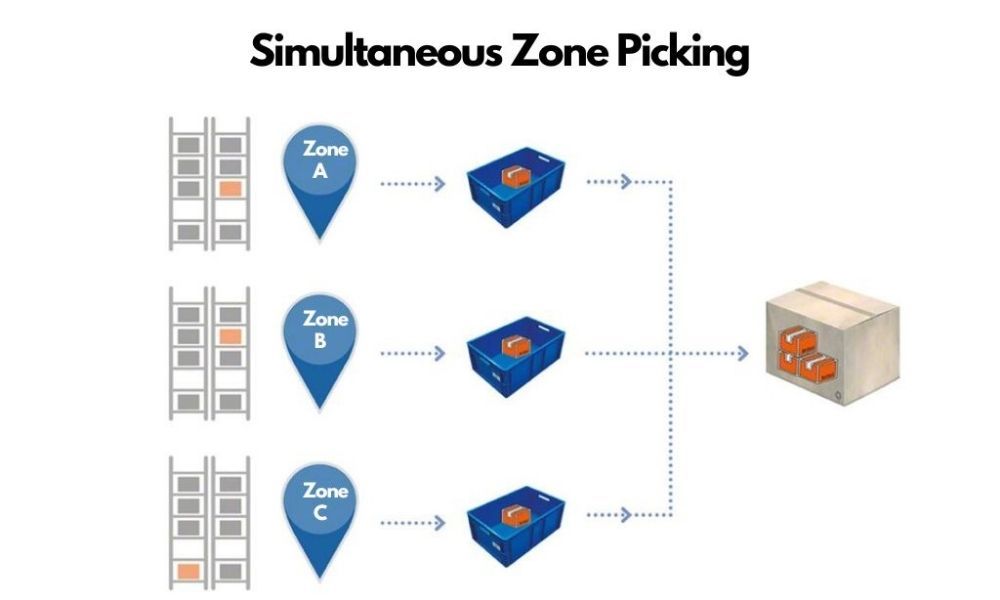

In this method, multiple zones are picked simultaneously in the same order. Each picker works on their assigned zone independently, picking items concurrently with pickers in other zones. Once item picking in the zones is done, all the items are consolidated and repacked downstream.

With the same customer's order in the example above, while one picker in Zone A gets the smartphone, another in Zone B gets the laptop, and a third in Zone C grabs the accessory, all at once, and then brings them together at the packing station.

Simultaneous zone picking is usually used for larger orders with flexible processing times and can help alleviate delays caused by hold-ups or bottlenecks.

👉 Read More: Wave Picking In Warehouse: Definition, Example

👉 Read More: What Is Batch Picking? Example And Advantage

Zone picking, like any system, has its downsides that may make it necessary to consider other or combined picking strategies. Here are some of the key challenges:

Zone picking involves multiple touchpoints or stages in the picking process. Each order passes through multiple touchpoints as it moves before reaching the sorting and packing station. Keep in mind that each touch point increases the risk of error and time delays.

Additionally, handoffs between zones can lead to miscommunication or mishandling of items, resulting in inaccuracies in order fulfillment.

In simultaneous picking, items for the same order may be gathered from multiple zones, requiring bundling before dispatch. This adds an extra step and could prolong delivery times.

Since zone picking is a decentralized process, it might be hard to identify errors in it.

Mistakes may go undetected until the order reaches the consolidation stage, making it difficult to pinpoint which zone or picker is responsible for the error. However, this error-tracing problem becomes less of an issue if you're sure about the accuracy in your order fufillment process.

Zone picking often operates within one scheduling period per shift, which may lead to in an uneven allocation of workload.

While this can help managers plan shifts well, it means all orders must meet a specific cutoff time. Orders placed after this time are delayed until the next shift, possibly delaying customer orders.

A study shows that zones can become more congested during peak periods or when there's a high volume of orders coming in. As a result, some zones might get overworked while others are left empty, causing potential blockages (even propagate throughout the network).

Workload inequality among workers can arise in zone picking, where some zones may have higher pick rates or more complex picking requirements than others.

Not to mention, picking also requires a lot of physical exertion. Compared to colleagues in slower zones, pickers in high-traffic zones could feel more exhausted. Factors such as zone layout, SKU velocity, order volume, and equipment availability can further exacerbate workload inequalities.

All of these can lead to disparities in picker productivity and efficiency, as well as uneven distribution of labor resources across zones.

Overall, zone picking brings a significant boost to warehouse operations, increase productivity, and deliver a better customer experience, especially warehouses with a wide variety of products.

Here are some main impacts of zone picking:

Zone picking allows for a more flexible approach to order fulfillment. By dividing the warehouse into zones based on product type, demand, or other criteria, businesses can customize their operations to meet specific needs.

This flexibility enables them to adapt quickly to changes in customer demand, seasonal fluctuations, or new product lauches. They allow for different processes to be used in different zones and products, based on what works best for your business.

For example, some zones may be better suited for picking single orders while others are more efficient for picking in batches. Additionally, specialized equipment can be allocated to specific zones, save and optimally use resources.

Limited to one zone, pickers naturally become more attentive to their area of responsibility. With a focused scope of work, they have less information to remember and more time to familiar and keep track of the items in their assigned zone.

Therefore, workers can develop expertise in handling the products assigned to their zone. They will enhance their awareness and problem-solving skills when dealing with any issues or uncertainties specific to that zone.

When pickers stick to smaller, designated zones in the warehouse, they don't have to spend as much time moving around, which really cuts down on travel time. Not to mention, since they know their zones inside and out, they can grab items faster.

Less travel time means workers will be more productive and get more done. And when multiple pickers can pick different items for one order at the same time; consequently, orders get fulfilled faster and more effectively.

Besides improve picking speed, zone picking method may also boosts the accuracy of order pickers.

By focusing on a single zone, the process becomes more straightforward with fewer criteria to consider within that area. This eliminates the need to gather complex combination orders from multiple zones scattered across the warehouse.

Furthermore, as metioned above, working within a smaller zone allows pickers to become intimately familiar with the SKUs and their locations. This familiarity reduces the chances of mistakes and ensures that orders are picked accurately, leading to higher customer satisfaction and fewer returns.

Undoubtedly, zone picking is one of the great way for enhancing warehouse efficiency. It helps boost productivity, minimize errors, and refine inventory accuracy, ultimately adding up to happier customers, smoother operations, and saving money.

But, it's not a one-size-fits-all solution. Zone picking works best when it matches your business goals and is done right.

If you're having troubles with zone picking or any other order fulfillment issues, don't hesitate to get in touch with EFEX!

We offer the most optimal solution for e-commerce order fulfillment, and warehouse service with unexpected benefits at the most cost-effective. Your focus can now be on driving sales, while EFEX takes care of the rest for you.