More Helpful Content

Inventory management is complicated, including several parties, suppliers, SKUs, and manufacturers, and is sometimes influenced by variables outside the buying or planning departments’ control. Choosing how much inventory to store is not an easy issue. However, it is important to save up cash and reduce potential customer service concerns.

Inventory levels might contain both cycle stock and safety stock. Both components should be computed per SKU and changed over time to minimize the cost of carrying versus other risk variables.

Today’s article will just focus on one component which is cycle stock. To learn more about cycle stock, let’s spend some time reading through this article to understand what is cycle stock, its importance, also its formula.

Cycle stock, also known as working inventory, is the quantity of inventory available to fulfill average demand for a particular period. Depending on estimates and historical data, it is the quantity of inventory you would anticipate to go forward. Cycle stock is a component of a corporation’s total on-hand inventory that must be replenished when the company sells its products, in another word, it is inventory turnover.

👉 Read More: What is Buffer Stock?

👉 Read More: What is Cycle service level: Formula and Example

Cycle stock is critical to a company’s daily operations since it is utilized to satisfy the majority of sales orders. Without it, a firm could not have enough stock to fulfill client demand and could go out of business. The stock is also essential for organizations that generate cash flow. The organization gathers money and creates cash flow when products are sold.

As those commodities depart the warehouse, the company must make replenishment orders with multiple vendors, which it funds with money from cycle stock sales.

Furthermore, it is included on the balance sheet as a component of the company’s total assets. The cycle stock can be valued by using FIFO or LIFO approach. The identical amount is subsequently entered into the income statement.

👉 Read More: What is Goods Receipt? Process and Template

Handling cycle stock inventory gets much easier if you detect regular sales trends and have past data to refer to. When done correctly, businesses can be confident that the proper items are accessible in the right quantities and are effectively refilled. The quantity of cycle stock required by a new firm might be difficult to forecast.

It may be beneficial to speak with similar firms or industry experts to determine the proper amount to carry. When determining the optimal quantity of cycle stock, consider significant marketing campaigns, periodicity, and related trends. Businesses can produce more detailed and reliable demand estimates if they have some data to work with. They will get an understanding of how sales fluctuate over a year, which SKUs are the quickest and slowest, and other relevant information.

👉 Read More: What is Direct Store Delivery (DSD)? Example and Model

In this circumstance, inventory management software is widely employed since many systems include a demand planning engine that analyzes historical data, seasonality, trends, and other factors to estimate future sales. This application may calculate the amount of cycle stock necessary for each product sold by the company to last a given amount of time.

The goal is to keep adequately cycle stock on hand to stay until your next purchase order comes, whether in a manufacturing plant, store, or warehouse. The duration between receiving orders or between production runs is frequently used to determine cycle stock (in industrial settings). The majority of the cycle stock should have been sold by the time the next replenishment shipment arrives.

Forecasting is critical in calculating the proper quantity of cycle stock to carry. The following are a few crucial advantages of anticipating cycle stock.

Forecasts reduce the possibility of running short of specific products. For example, if a few sizes of sweaters flew off the racks last winter, the system will notice and raise the order size for those specific goods. Under-ordering can save money in the short term, but the company executives will be disappointed once they learn the demand is there but the supply is not, and they are losing income.

Forecasts save you from having insufficient items on hand, but they also keep you from owning too much inventory. It will cost money to maintain products in a store or warehouse, and retaining the correct number prevents you from incurring needlessly high inventory carrying costs.

Businesses that do not buy adequate inventory typically burn through their safety stock, negating the very purpose of having it. Safety stock should be kept on hand in case of substantial disruptions, such as suppliers shutting down caused by natural disasters or extraordinary demand for a certain item. Forecasts assist guarantee that your safety stock stays just that: safety stock, not cycle inventory.

If your company is rapidly running out of specific commodities, it will begin hustling to obtain new goods or supplies from vendors. This frequently results in rush shipments, which are more expensive and reduce profit margins. It also might attempt to discover alternative suppliers that can deliver the same or comparable items quickly, which would be a lot of work. Forecasts might assist you in avoiding confusion and problems.

Top forecasting programs use a large amount of data and utilize algorithms to provide projections. It is difficult to reproduce it by analyzing the statistics and using simple math. Forecasting software may take into account a fresh tendency that you have not yet seen or something you missed in the last year.

You have previously learned that cycle stock is significant in accounting since it generates cash, and acquiring more of this inventory to fulfill demand has an impact on cash flow. Any inventory that a corporation has appears as an asset on its accounting records. Companies can use various methodologies to calculate the costs of goods sold for inventories.

Because prices change, the inventory costing technique adopted might impact the costs of goods sold and lead to gross profit. The following are the most widely used and GAAP-compliant costing methods:

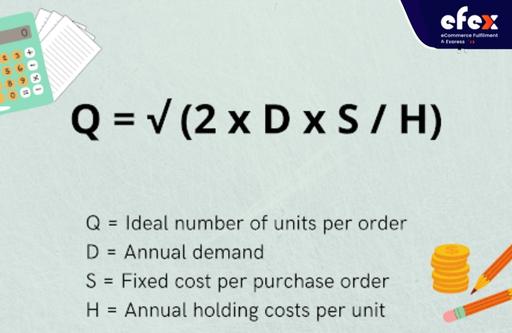

The formula of economic order quantity which is known as EOQ is widely used. This method enables a company to purchase enough inventory to fulfill demand while reducing expenditures for each order. When determining EOQ, you must account for your ordering expenses, holding costs, and product demand.

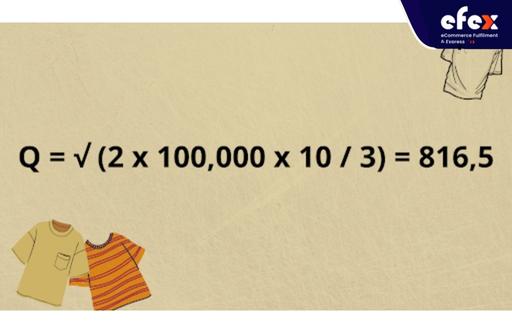

For example, you run a retail store that sells 100,000 T-shirts every year. Your fixed order cost is $10, and storing a T-shirt in your inventory costs you $3 per year. Applying the above calculation, you will have:

This indicates that (result) T-shirts are your recommended order size. However, you should calculate the appropriate quantity of safety stock and add it to this figure to get the overall amount of inventory you should maintain on hand.

Cycle stock is an important component of your entire supply chain management strategy (SCM). Maintaining the proper quantity of inventory on hand entails placing orders to the right provider at the proper time and making modifications depending on how quickly things sell.

Determining the most cost-effective strategy to ensure that everything runs well is difficult, which explains why firms have devoted more resources to SCM in past years.

For instance, suppose cycle stock for a specific item increases from 1,000 to 2,000 as a result of a marketing campaign and hot influencers both featuring your product. Because your current supplier may only be able to deliver 1,500 units, you will need to locate an alternative partner who can supply the extra 500.

Likewise, if the prediction predicts that sales for a category of products would quadruple this year based on the constant growth over the previous year and a consistent rise in demand throughout the year, this might have an impact on downstream supply chain partners. You should consider whether your present shipping carriers can handle that amount, and if they can, can you obtain volume discounts or not.

If the rates are prohibitively expensive or they lack capacity, you may need to locate a different courier. When monitoring and adjusting cycle stock, it is critical to evaluate the complete impact on your supply chain.

Because cycle stock comprises products used to satisfy regular sales orders, you must count all of the things on hand. For instance, in a retail context, the shop should contain things in the warehouse and on its shelves at physical locations. The quantity of cycle stock is then calculated by substracting safety stock from the overall inventory number.

Assume a fashion business finds out there are 500 bags in its stores by physical counting. The inventory management system informs the manager that 100 of those bags have been designated for safety stock. That indicates the retailer’s bag cycle stock will be 400.

If the business breaks down the bags by brand, color, or both, it might provide the firm with a more detailed tally of cycle stock.

👉 Read More: What Is Electronic Product Code (EPC)?

Cycle stock is critical to a business’s survival. Without it, the business cannot exist. But a company must appropriately compute this stock. A higher quantum incurs greater expenditures, whereas a lower quantum may result in revenue loss. To aid with the computation, a firm may implement an inventory management system, which would give management all of the data required to precisely estimate demand and determine the optimal amount of cycle stock. Hope you have a good time with Efex.