More Helpful Content

Out-of-stock is nearly always on the list of a store owner's "worst nightmares," and for understandable reasons. It not only loses orders but being out of stock reduces consumer pleasure and loyalty. Customers are frequently upset when they receive a response that is out-of-stock, and as a business owner, the last thing you want to do is upset the consumer.

It is a serious issue for business, especially in these uncertain times, and it not only results in a loss of income due to unfilled orders, but it also has a bad influence on the company's reputation and client loyalty.

Hence, this article will provide the primary reasons for what is a stockout, why a stockout happens in a warehouse, the risk, and the best methods to be applied to minimize or reduce the likelihood of it occurring.

When buyer orders for an item exceed the amount of inventory maintained on hand, a stockout happens. This occurs when demand exceeds expectations and typical inventory and safety stock are insufficient to meet all requests. Stockouts can also occur as a result of supply chain delays or interruptions in a company’s manufacturing process.

Customers are more inclined to go elsewhere for the essential supplies when there is a stockout, increasing the risk of missed revenue. Long-term consumer relationships may suffer as a result of this.

In a physical store, this typically indicates that there are noticeable gaps in the shelves. Stockouts are even more aggravating for online customers since there is sometimes no way to tell if the out-of-stock is due to a brief technical issue or a severe interruption in the retailer’s supply chain.

👉 Read More: What Is Buffer Stock: Example And Advantages

👉 Read More: What is return merchandise authorization (RMA) And Process

For various reasons, a stock-out scenario is troublesome for both suppliers and retailers. The data below is based on thorough research on a retail out-of-stock decrease in the FMCG business done by experts at the University of Colorado and IE Business School Madrid.

For suppliers:

For retailers:

Since these findings are upsetting enough on their own, the figures on stock-out expenses show how catastrophic OOS incidents can be for a company. According to ECR Europe and Roland Berger Strategy Consultant showed that there were 30% of consumers feel that stockouts cause bad impacts on their shopping experience.

👉 Read More: What Is Backflush Costing: Example, Journal Entries

It also indicated that when consumers know that the brand they were going to buy the product was out-of-stock, 37% of them changed to a different brand, while there were 21% of buyers changed to other locations of the brand to look for the product. 17% of buyers returned the purchased item later and 16% of them would buy another item from the same brand.

Finally, only 9% of customers decided to don’t buy anything when the product was out-of-stock.

Even though there are just a few potential effects of stockouts, such as consumer displeasure and lost sales, there are several events that might lead to stockouts in the first place.

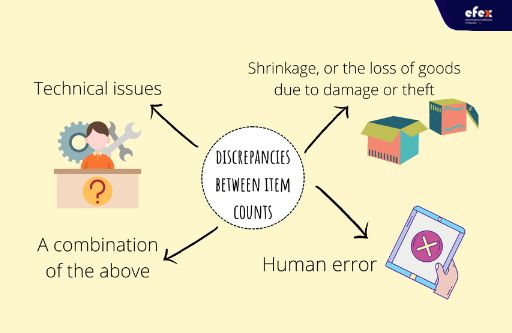

A discrepancy between item counts and the records of how many quantities of a given item a store has in store is a typical cause of stockouts (also known as phantom inventory). Though it's hard to measure, human error is frequently to blame for inventory management errors. During hectic shopping seasons, especially in retail outlets, it is all too simple to miscount products.

Differences in item counts can also be influenced by technical issues. Computerized inventory management systems are used in the majority of warehouses and distribution hubs. However, when those programs have technical challenges, like data center outages, or when synchronization between two computerized systems is delayed, disparities in item counts might develop.

Unexpected increases in customer demand frequently generate stockouts and inventory bottlenecks in general. Inadequate demand forecasting or erroneous reporting, on the other hand, might result in out-of-stocks.

Most merchants could pretty much tell you their most popular SKUs off the top of their heads. Yet many unintentionally allow their most popular goods to sell out due to insufficient forecasting. If a store is unable to adequately predict demand for a given item, it is practically certain that some consumers will be dissatisfied when that item becomes unavailable.

Likewise, erroneous reporting might result in stockouts. Retailers can only make business judgments depending on the information at their disposal. Making educated judgments regarding inventory purchases becomes exceptionally challenging if sales figures are wrong.

Retailers have recently faced several supply chain challenges, including hundreds of thousands of emptied containers with products on ships waiting to arrive at ports across the world. Besides shipping, the Covid-19 epidemic has wreaked havoc on the global supply chain, affecting everything from production to transportation and logistics.

Furthermore, a logistics supplier's shipping manifest may imply that a package is on its way for delivery while, in reality, it is still being processed in a distribution center. When you multiply these issues by the millions of goods that must be sent to hundreds of shops, it becomes evident how vital precise logistics data is.

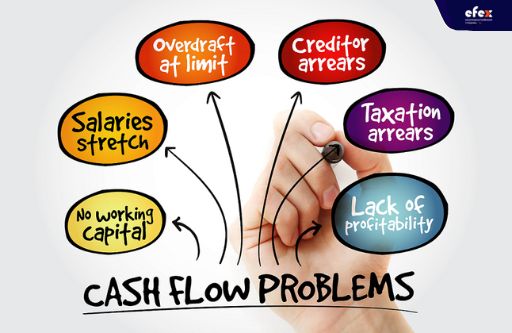

Stockouts can also be caused by cash flow issues. You can know how much inventory is required, but without sufficient funds, you cannot acquire it. If a lack of cash flow is generating stockouts, greater planning and finance might assist.

Stock replenishment entails ensuring that you still have enough items to sell at the appropriate moment. According to research, inadequate shelf replenishment methods account for 70% to 90% of stockouts, with supplier shortages accounting for just 10% to 30%. Stock replenishment is becoming increasingly critical in the omnichannel retail world, in which you must give the finest product offerings available, both online and in-store.

Stockouts may have a big influence on the consumer experience as well as your business.

The worst consequence is losing a client due to a stockout, and it comes at the biggest expense to the seller. Consider how much time and effort you put into attracting your consumers to visit your online store. Because a client no longer places orders with vendors, each order represents a cost that must be assessed.

If you run out of product, you will not only experience a decrease in conversions, but you may also lose clients to existing competition. That consumer is unlikely to come back to your online store in the future. 91 percent of clients are unwilling to deal with a bad-experienced online shop.

This occurs when a consumer pays for a product that is out of stock before they attempt to purchase it. This occurs only when the business owner's inventory is mismanaged and the inventory amount is wrong. If this occurs, contact the client to cancel the order and request a refund.

Not only does canceling purchases raise the cost, but it also gives an unsatisfactory experience. There is also the expense of attempting to alleviate customer displeasure, either by offering benefits for them to shop from the seller again or by promoting to eliminate any unfavorable social media posts.

Consumer reviews are probably to generate a significant amount of income for you. However, negative reviews might have a negative impact on your business. Customers who frequently discover your goods out of stock may provide bad feedback on your shop or other parties. When potential consumers see these evaluations, they may get skeptical and conclude that you are an untrustworthy supplier.

Fortunately, many of the deeper causes of stockouts may be avoided by using effective processes. Suppliers should work on improving their retail performance and supply chain procedures to reduce stockout risk.

As a general guideline, organizations should strive to eradicate out-of-stock for the 20% of goods that represent 80% of overall sales in order to have the largest impact on the bottom line.

As previously stated, stockouts frequently occur when product counts vary from one inventory management system to the next. While completely reducing human error is nearly impossible, making sure that inventory information is up-to-date is rather simple.

Synchronizing inventory data among online platforms and physical locations makes it a lot easier for merchants to successfully manage their supply. It also assists retailers in providing a far better shopping experience to clients who utilize more than one channel.

According to current statistics, the great majority of customers begin their product research online and determine whether items are available for in-store pickup before going to the store. To properly service these customers, retailers must have correct inventory data shown on both their online store and their point-of-sale (POS) system.

Conducting an ABC analysis makes it simpler for certain businesses than others to estimate how much inventory will be necessary and when. Companies that rely heavily on seasonal commodities, like winter sports equipment or beachwear, may discover it considerably simpler to forecast demand for certain products.

However, there are strategies for all sorts of shops to forecast demand and prevent stockouts. When developing inventory projections, merchants should include lead time—the period between placing an order for new items and getting them from a supplier.

Examining prior purchase orders from certain suppliers is one technique to estimate lead time. This is unlikely to be sufficient on its own, but it may be used as a starting point for determining the lead time from particular vendors. The demand for certain items during the time it takes for a replenishment order to arrive is referred to as lead time demand.

While measuring lead time can help merchants plan for busy shopping seasons, companies face stockouts if they fail to account for lead time demand.

Thankfully, determining the lead time needed is a straightforward process. Retailers can assess lead time demand by dividing the average lead time in days for a certain product by the average number of units sold each day. The resultant number represents the lead time demand.

Another issue merchants should consider when forecasting projected demand for certain items is "safety stock," or the quantity of stock a shop has on hand to create a buffer zone for unexpected increases in demand. Even though this buffer will differ from shop to store, business owners can determine their safety supply using the formula given:

Retailers who are worried about precise inventory prediction may also depend on data-driven solutions to ensure that their best-selling goods do not run out.

According to The Fragrance World, social and reality TV marketing frequently result in out-of-stock incidents. Katie Johnson, the company's founder, recalls a moment in June 2021 when a popular Love Island star recommended a specific fragrance. "That evening, we completely cleaned our shelves because everyone was racing to acquire it," she adds. "It's much more difficult to generate a large inflow of orders when it's a lesser selling item."

The Love Island episode altered The Fragrance World's strategy to inventory management. Katie also prepares The Fragrance World for these occasions by anticipating and emphasizing any potential surges in trends in order to guarantee that the product is accessible. "We now always plan ahead of time." "We order [stuff] as far in advance as possible so that we always have a spare batch on hand," Katie explains.

RT1Home, a premium home, and gardening product shop receive a lot of press exposure from websites like BuzzFeed and The Knot. It's difficult to avoid a stockout in these situations, but creator Rhiannon Taylor has discovered that an early response is critical. "Restock it as soon as you become aware of a sales surge due to a news story or influencer."

Rhiannon suggests performing inventory inspections on a regular basis in her day-to-day operations so that you are constantly aware of stock levels. This allows you to produce things (if you manufacture in-house) or order wholesale from providers.

Stockouts are common for store Surf Gear Lab during major holiday shopping weeks such as Memorial Day, Black Friday, and Cyber Monday. Marc Bromhall, the company's founder, employs inventory management software to automate duties such as managing inventory, tracking, and optimizing. Human error is common in these jobs, resulting in stockouts.

According to Marc, the program has "enhanced our demand forecasts by a country mile," allowing the retailer to study inventory records and previous sales data. "This allows us to operate at an optimal stock level." Just enough to meet demand throughout the year while lowering our inventory costs because we are never overstocked."

- Read More: Order Management System: Definition, Process And Value

- Read More: Order management system for Ecommerce: Definition, Key Effect, Benefit

Stockouts do not just result in dissatisfied customers. They sometimes represent lost chances. Once popular goods are out-of-stock, it is like businesses are throwing money away and urging their customers to spend elsewhere. It is also a waste to lose revenues due to stockouts in the twenty-first century when modern technology for forecasting demand and replenishing can be swiftly connected with your ERP or e-commerce systems.

Applying technology to your warehouse will assist you in avoiding stockout problems, maintaining a healthy turnover ratio, and keeping your stores supplied with the appropriate amount of merchandise since effective inventory management is critical for your e-commerce business's long-term profitability and growth. Hope you have a nice day with Efex.