More Helpful Content

Businesses can provide a pleasant customer experience in a variety of ways, one of which is through streamlining the order management process. In which, order fulfillment cycle time is one of the most critical elements boosting order fulfillment and accuracy rates. Indeed, it's not enough to ship the goods on time in the eCommerce process. Enough is no longer enough for online shoppers. Therefore, optimizing your order fulfillment cycle time can help your brand get more trust, then become a preferred brand.

Keep reading our post to learn more about the order fulfillment cycle time to help improve your business operations.

The order fulfillment cycle can be known as the time it takes for a consumer to buy a product and have it delivered to their doors. Determining your OFCT provides you with crucial data about the efficiency of your order fulfillment process, tracking the customer data from online buying shows that customer satisfaction heavily depends on timely delivery.

>> Learn more:

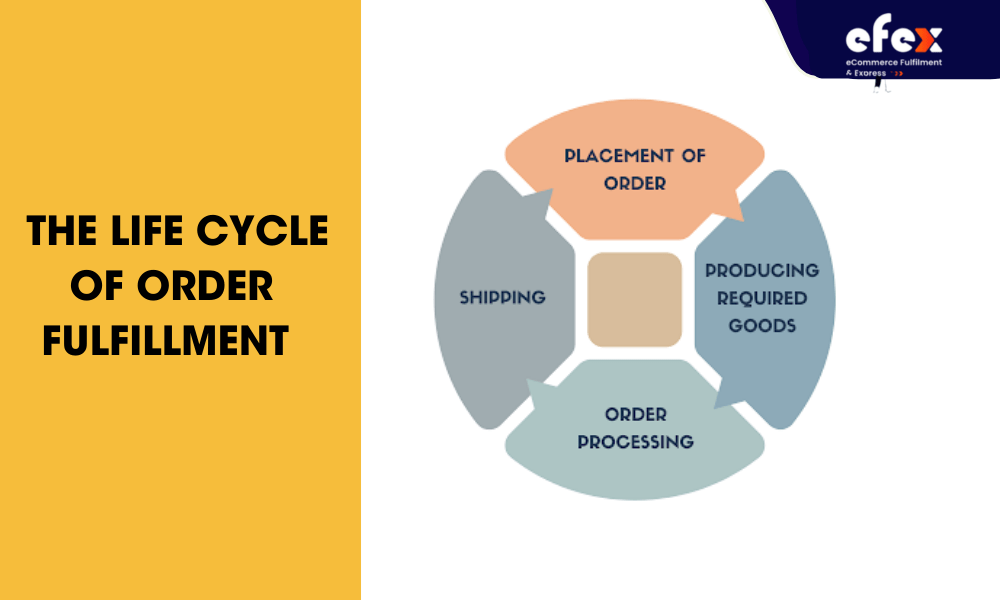

The order fulfillment life cycle involves a set of phases from the time you receive a customer order to the time it is delivered to them. Here are those phases:

Once a buyer makes a purchase on the website, social media, or an eCommerce platform, the order fulfillment process begins. Then, the customers will get an email after the shop receive the orders.

This phase will be completed depending on retailers' order fulfillment strategies. The goods are already available to be shipped, and the next phase of shipping occurs.

This phase includes taking the goods from the warehouse, inspecting them for detects, packing them, and sending them to the shipping carriers.

The ready-to-ship packages are sent to third-party carriers. The optimum delivery choice is determined by the product's weight, size, and measurements.

The order fulfillment cycle can take several days, even several weeks if something is beyond your control. No matter what will happen, you need to make sure to remain your OFCT at the low level as possible.

So, what can you do to optimize your OFCT?

As you know, managing order fulfillment time becomes increasingly difficult as your company expands when you have to depend on many entities such as warehouses, team members, workstations, and so on. To finish the order fulfillment process, these departments have to work together effectively, maintain good communication and utilize the other sections of your supply chain.

Your order fulfillment cycle may be calculated in a variety of ways, therefore your OFCT can relate to a variety of metrics:

- Read More: What Does Order Status Fulfillment Mean?

- Read More: What is Order Fulfillment? Strategies and Process (7 Steps)

- Read More: What Is Fulfillment Center And How Does It Work

As your business grows, your order fulfillment process’s also getting more complex. Having great products can no longer ensure a successful online business: more products, orders, and customers can easily translate to delays and bottlenecks.

That’s when a finely tuned order fulfillment comes into play. Here’s how shaving time off each stage in your order fulfillment process and contribute to the success of your business:

Customer loyalty is everything, especially when you are scaling your business. Twenty percent of your customers will likely return for repeat purchases, contributing significantly to your revenue over time (the 80/20 rule).

A fast and efficient order fulfillment process will then demonstrate your commitment to customer satisfaction. When customers know that they can rely on you for quick and hassle-free delivery services, they are far more likely to choose your products again and again. This way creates repeat businesses and positive experiences, which are believed to be the foundation of long-term success.

The order fulfillment process is like a trust-building exercise for e-commerce merchants. From the moment the buyer clicks to buy your products to the day their package arrives, each action you take will show them how reliable you are.

When you improve the order fulfillment cycle time and deliver on promises (and quickly), they know that they can rely on you for future orders. This kind of trust also leads to better reviews, strong word-of-mouth, and repeat businesses.

As mentioned above, positive reviews on fast shipping services can create strong word-of-mouth and be a game-changer as you expand your business (and customer base, of course!).

When it comes to online selling, buyers are savvy and prioritize delivery times when comparing the same products from different stores. Hence, if you have a proven track record of fast shipping and positive recommendations from past customers, you can easily win over your competitors.

A good order fulfillment cycle time is just about speed. When you reduce the fulfillment cycle time, you will also optimize your entire operation, make customers happy, and translate these into repeat purchases.

During the process, you might also reduces the likelihood and minimize costly returns. You can maximize warehouse space and manage inventory more effectively. Over and above that, it’s now much easier to communicate and collaborate at the department level.

To be competitive in the eCommerce business, you must keep your order fulfillment cycle time to be optimized at a low level. However, given sourcing goods and parcel delivery are both outside the control of businesses, regulating the cycle time can be hard.

- Read More: Ecommerce Order Fulfillment Guide: Process And Strategy To Improve

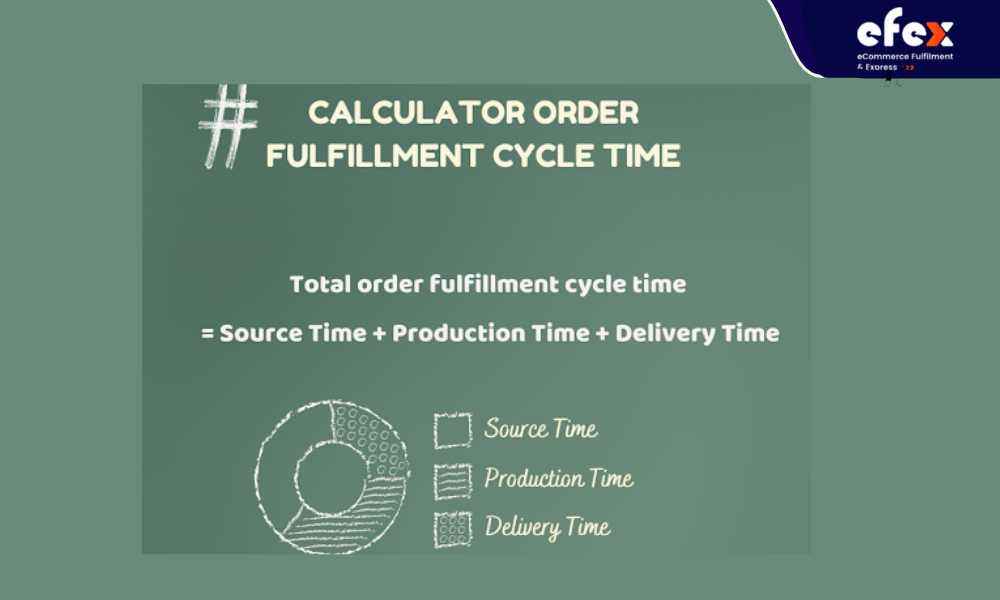

Using the order fulfillment cycle time formula will be the way to enhance the process. Here is the order fulfillment cycle time calculation:

The order cycle time can not meet your desires? Here we provide you with useful solutions to increase your operations' efficiency and minimize your total order cycle time. Though the details of your business will influence your approaches for improvement, many order fulfillment operations may increase their total order cycle time in 3 ways.

Considering the distance traveled to accomplish a task is one of the easiest ways to minimize cycle time because the longest part of the order processing cycle is travel. The amount of time it takes for raw materials to arrive at a retailer's warehouse has a big impact on the entire cycle time. With this in mind, purchasing materials from nearby wholesalers or manufacturers not only can greatly reduce travel time but also help lower shipping expenses as well.

While items from local wholesalers may be more expensive, they are worth it since they may save transit time and shipping expenses.

Warehouse congestion might contribute to lengthier order cycle times. Can pickers locate goods quickly? Are the shelf racks properly placed so that they may be moved around quickly? Is your fulfillment center located too far away from the picking area? All of these will make the picking and packaging process take longer.

Besides, the overall order fulfillment cycle time can be influenced by the layout of a retailer's warehouse. Workers can work more efficiently in a space that has been optimized. You can shorten the order cycle time by detecting bottlenecks. To make the most of available space and boost picking efficiency, you may need to optimize your warehouse setup and utilize warehouse slotting. A warehouse may be optimized in a variety of ways. Reduce the distance between coordinating teams, for example.

This phase reduces the time it takes for a shipment to transit from one team to the next. Shifting important resources to high-use locations is also a wise decision.

Once running out of stock, one of the most losses to production, then hence your entire order cycle time happens. The bad thing is that business operations will be entirely shut down while you wait for a new supply of the required material or product. As a result, this substantially reduces your overall efficiency and capacity to satisfy your customers' expectations for timely delivery.

You may avoid this situation by using technologies that track inventory automatically and alert you when a reorder is required before you run out of stock. In recent years, supply chain technology has dramatically advanced.

In fact, manual inventory management and storage just do not make sense when it comes to modern eCommerce. The sourcing, production, and even delivery processes may all be automated using various warehouse management systems. Using technology in the order fulfillment process helps reduce mistakes and speed up both order cycle time KPI and your business operations.

👉 Read More: What is Cycle service level - Formula and Example

Improving your order fulfillment cycle time doesn't have to be a constant uphill battle. With EFEX as your trusted fulfillment partner, you can unlock a new level of speed and efficiency.

Here's how our unique combination of technology, expertise, and strategic solutions can help you reduce your order fulfillment cycle time:

Over and above that, at EFEX, we're committed to transparency and accountability. Our professional SLA measurement and reporting system provides real-time visibility into your order status. They also handle every package with care, upholding the highest standards of quality and accuracy throughout the entire fulfillment journey.

Looking for a fast shipping option as well? We are expanding our services to include expedited shipping options, including two-day and same-day delivery.

The order fulfillment cycle encompasses every step involved in getting your product from your "digital shelf" to your customer's hands.

A smooth, optimized fulfillment cycle is essential for driving sales because it directly impacts the customer experience. Fast shipping, accurate orders, and timely updates all build trust and satisfaction, encouraging repeat business and positive reviews.

The duration of an order fulfillment cycle varies greatly depending on several factors. These include the type of products you sell, your warehouse location and efficiency, the shipping methods offered, and even external factors like carrier volume and seasonal demands.

For example, a complex order with customized items might take several days to process. Meanwhile, a standard product shipped from a well-stocked warehouse could go to the customer within 24 hours.

Accurate and complete order information is crucial for initiating a smooth fulfillment process. This includes essential details such as the customer's name and shipping address, the specific products being ordered and their quantities, chosen shipping methods, and any special instructions or delivery preferences.

Calculating your order fulfillment cycle time is essential for understanding your operations' efficiency. It helps you better understand your operation's efficiency and identify potential bottlenecks to optimize each process stage.

Here's how you can do it:

Order Fulfillment Cycle Time = Source Time + Production Time + Delivery Time

Let's say a customer orders a custom-designed phone case from your store. It takes 2 days for your supplier to print and ship the case to your warehouse, 1 day for you to package the case, and 3 more days for the shipping carrier to deliver the package to the customer. In total, your order fulfillment cycle time is 6 days.

Order delivery cycle time refers specifically to the time it takes for a package to travel from your warehouse or fulfillment center to the customer's doorstep.

Optimizing delivery time can significantly impact your overall efficiency since faster delivery times equate to happier customers who are more likely to return for repeat business.

The average order cycle time is the typical timeframe for completing all the steps in your order fulfillment process. It gives you a big-picture view of your order fulfillment efficiency.

Order cycle time varies greatly depending on factors unique to your business, such as your product types, warehouse locations, shipping methods, and even the complexity of your orders. Hence, there isn't a magic "average" order cycle time for any industry.

One of the most important KPIs for any order fulfillment, e-commerce, or supply-chain management operation is order fulfillment cycle time. Investing time and effort into optimizing this process, as well as trying to improve your cycle time, may help your business scale and develop. COVID-19 wreaked havoc on most businesses, particularly retailers who relied on only one or two suppliers.

For advanced order fulfillment and a seamless customer experience, consider integrating an efficient Fulfillment Platform into your operations. Experience the benefits of a comprehensive order fulfillment service with EFEX. Start optimizing your order fulfillment cycle time today to drive business growth and enhance customer satisfaction with EFEX's order fulfillment service.