More Helpful Content

In product inspecting, the industry usually uses the AQL as the sample standard. Acceptable Quality Level is a popular sampling criterion for assessing the sample size to be examined as well as the number of flaws that will assist you in determining whether to approve or disapprove an inspection batch of material.

As compared to a hundred percent examination of all items, the AQL’s random sampling technique helps to save time and money.

The Acceptable Quality Level or AQL is a term used in quality control. It was initially known as an acceptable quality level and was renamed acceptable quality limit in 2008.

This is the basic minimum of flaws permissible in a sample of a product that is produced for the full batch to be approved. If the number of defects exceeds the AQL, the whole batch is discarded.

👉 Read More: What Is Landed Cost? Meaning And How To Calculate It

In a simpler explanation, AQL is a sample approach used for product entering examination. The choice to accept or reject a large number of newly received materials is dependent on the number of things that potentially fail when sampled and examined.

AQL works by testing a random sample of products, and if the quantity of defective products is less than a set quantity, the product is deemed to satisfy the acceptable quality standard.

In contrast, manufacturers will examine the numerous factors in the manufacturing process to identify the sections producing the defects.

Assume a 1% AQL on a manufacturing run as an example. This figure indicates that no more than 1% of the batch may be faulty, which means only 10 goods can be faulty in a 1,000-product production line.

If 11 goods are found to be faulty, the whole batch is discarded. The rejectable quality (RQL) is defined as 11 or more faulty items.

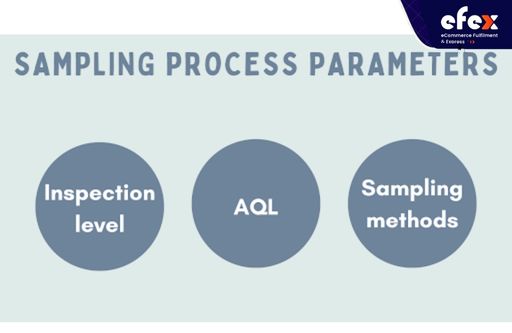

The sampling procedure necessitates the establishment of several preliminary metrics, including the AQL, which will be used to make the ultimate decision on whether to approve or disapprove a batch of goods. The parameters are as follows:

It includes three levels which are standard, tightened, and decreased to inspect. The standard level is typically used to inspect samples for flaws. The level is determined by the supplier’s performance.

Consistently bad performance results in tighter inspection, requiring a more stringent procedure. In contrast, a solid track record results in a lower degree of examination.

The amount of permitted flaws in a batch determines the acceptable quality level. The AQL is determined by the customer and supplier depending on the significance of the goods.

For instance, the AQL for a batch of hats can be 1/1000, although it is significantly lower for a batch of smartphone batteries, such as 0.001/1,000 or 1/1,000,000 defects.

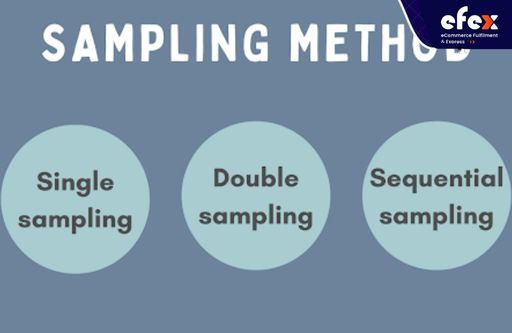

Depending on the amount of complexity and rigor necessary, a number of sampling techniques can be utilized to provide quality control. The following are the primary methods:

Besides, we also have other techniques such as skip lot sampling and multiple sampling.

There is a couple of additional ideas that must be learned before connecting all of the dots, including:

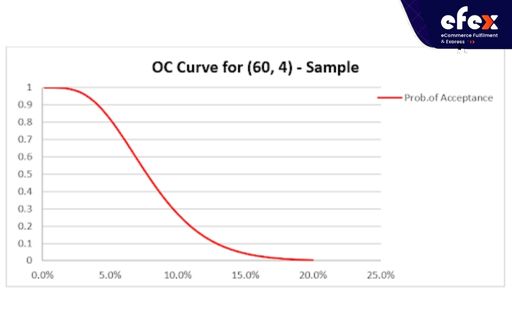

As the graph indicates, as the quantity of flaws increases so does the chance of approval. For those who are acquainted with statistics, this curve resembles a vital function.

As a result, the points on the curve represent the chance of a batch accepting given the proportion of defaults for a specific sampling procedure. A manufacturer aims to decrease the chance of refusal when creating a sampling procedure.

Therefore, they want to reduce as indicated above. Maximizing (1-) or the percentage of approval for a particular sampling procedure is the same thing.

The manufacturer selects the AQL based on the OC Curve and their understanding of other elements such as the quality of machinery and personnel engaged in the manufacturing process, the quality of the raw material, the quality desired by consumers, as well as any factors that impact quality.

The OC Curve may also be utilized to determine the best sampling strategy. The manufacturer can select the sampling strategy that increases the percentage of approval for a certain AQL.

Defects are known as circumstances of failing to fulfill customer quality criteria. In practice, defects are classified into 3 types, critical, major, and minor defects.

👉 Read More: What Is Universal Product Code And How To Get It

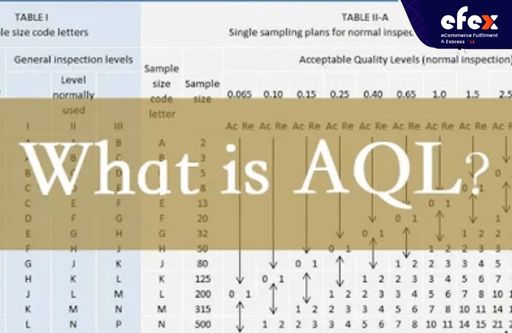

In actuality, the calculations are more complicated than those you have seen in the OC Curve part above. AQL charts are utilized to make the work of adopting the standards of quality easier.

The number of approval errors in a sample may be easily read from the graphs, based on sample size, AQL, and inspecting level. The graph shows approval and disapproval levels for a sample, which may be utilized to determine the final choice.

The arriving number of materials will not be turned down as long as the sampled flawed items are within the AQL scope. If the amount of rejected items exceeds the AQL, the whole batch is discarded.

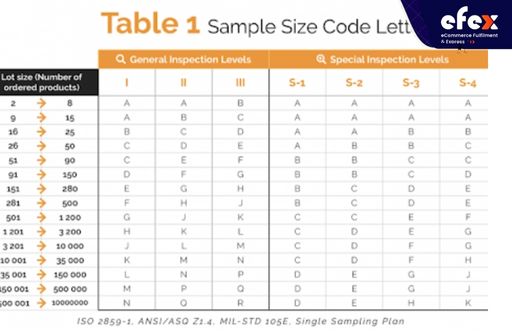

We have 2 tables that offer the information needed to decide whether to approve or disapprove the batch.

The first table, presented below, assists you in determining the proper size based on batch size and required inspection levels.

Suppose a batch of 20,000 hats has to be sewn and the inspecting level is assigned to Normal II. Based on the data, the inspection level is at the junction of the row of the batch size and the column of the inspecting level, which is the inspecting level “M” in the following table.

You can see that there are a total of 3 General Inspection levels including I, II, and III, and 4 Special Inspection levels including S-1, S-2, S-3, and S-4.

The Special Inspection levels which are S-1, S-2, S-3, and S-4 are used to inspect or check on-site on a small number of items in a batch. This is the case when an inspection necessitates harmful or time-consuming testing. The sample quantities required are less than for General Inspection levels.

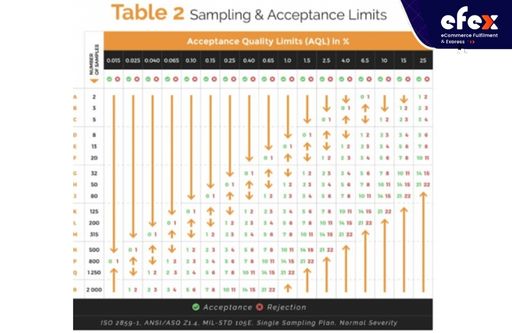

The second table which is given below will show you how many flaws or defective items you may identify in your samples before rejecting the entire batch.

All we need is to establish the proper sample size, select the AQL, and determine depending on the below table’s criteria. The criteria are calculated as the same as in the inspection levels table.

There are many online AQL calculators that you can find on the Internet. All you need is just enter the number you need into the calculator and it will then automatically calculate for you.

In this part, we will go through steps to help you use the calculator.

First, pick the ordered quantity or the batch size and the level of inspection for the goods to be verified. It will tell you how many samples to choose from for examination.

Second, provide the AQL limitations agreed upon by you and your supplier. You need to be aware of the total number of faulty components that are permitted.

Finally, it will show you the result you need.

👉 Read More: What Is Demand Variability And How To Reduce

During an inbound check, a fashion company discovered an unusually high number of flaws. They decided to begin utilizing ISO 2859 and AQL as a method to test the items arriving from their vendors more efficiently.

They put their new strategy to the test with their major supplier on a recently obtained lot size of 100,000 units. They went with General Inspection Level II (based on the above table in the Using AQL Chart part).

They are required to choose a sample size in Table 2 corresponding with the letter N because the 100,000 lot size ranged between 35,001 to 150,000 units as you can see on the left column of the table.

Table 1’s representative sample for the letter N is 500 units. They utilized a 1.5% AQL for significant problems and a 2.5% AQL for minor defects.

👉 Read More: Reorder Point (ROP): Formula and How to calculate it

According to the chart above, the batch will be discarded if 15 or more major flaws and from 22 above minor problems are discovered.

However, the inspection findings revealed 13 significant flaws but 25 minor flaws. The batch was rejected because it exceeded the permissible 21 units at the chosen 2.5% AQL percentage.

Accept Quality Level has become widely regarded as an effective way of random sampling in quality testing, taking estimated risks for consumers and suppliers into account.

It provides both consumers and suppliers with a quantifiable reference on how many faulty items are approved under a single inspection based on the AQL sample standards.