More Helpful Content

Capable-to-promise (CTP) is a broad approach to capacity and demand. Many aspects play into this type of system, involving raw materials of product, inventories, shipment, manpower, and supply chain concerns. By considering all of these factors, a CTP system may provide more accurate forecasts about what is achievable inside the firm.

It is a method that helps decide when a buyer’s purchase may be shipped. It entails many production or distribution sites and makes use of a finite planning model to calculate when a product will be completed. That is the reason why this approach is dubbed capable-to-promise since it gauges a company’s capacity to truly promise achievements to customers.

So, what is capable-to-promise? We will find out in this article right now!

The process of having committed orders against available capacity and inventory is known as capable-to-promise or CTP. This procedure may show how various production or distribution facilities. It decides when a new or unexpected buyer order can be shipped. It uses a manufacturing process finite-scheduling model to decide when a product can be completed. It contains any restrictions that may limit production, like available resources, lower-level components or subassembly criteria, and lead times for raw material or purchased components.

👉 Read More: What is part period balancing? Method and Example

👉 Read More: What Is Configure To Order? Example And Benefits

Consider that capable-to-promise can cause some following limitations:

While the capable-to-promise or CTP uses a finite-scheduling model to predict when a shipment will be achievable. It considers any manufacturing process limits that may impede production. These restrictions might include the time it takes to get raw materials or bought items, the access to critical resources, as well as the capacity to get resources required for lower-level parts or sub-assemblies.

In a capability to promise situation, the delivery date offered to a client takes into account not just manufacturing capacity, but also other promises made by the organization.

Whenever a new or unforeseen customer order arrives, the competent to promise mechanism is used to assess once the order can be delivered. The entire purpose of the competent to promise concept is to ensure that manufacturing planners spend less time modifying plans and rearranging orders since delivery-date guarantees cannot be honored.

There may be a further version of CTP by contrasting it with a related phrase known as Available-to-promise or ATP which relates to the constraints that must be imposed on shipment obligations. To use terminology more prevalent in the Japanese manufacturing business, ATP relates to shipping quotations. Its information comprises mostly of plausible delivery dates and amounts that may be given.

This is just as vital for e-commerce platforms as it is for brick-and-mortar stores. Companies should emphasize the capacity to deploy goods and resources (both employees and equipment) depending on predicted and actual demand. This allows delivery dates to be precisely calculated. Failure to offer appropriate timetables may result in a misleading advertising charge. The idea of ATP is crucial in supply chain management. It enables businesses to give precise available amounts and consistent delivery dates.

👉 Read More: What is Lot-for-lot? Example and Formula

There are several methods for determining needed quantities and practical delivery schedules. The tactics employed will be determined by the individual conditions of the firm.

| Capable-to-promise (CTP) | Available-to-promise (ATP) |

| It takes into account both material availability and capacity. | It merely takes into account material availability. |

| It provides a clear picture of the ability to meet demand within a specific time frame. | It is unable to give an accurate picture of demand fulfillment capabilities within a certain time frame. |

| The calculation is more complicated and time-consuming. | The calculation is straightforward and takes little time. |

To summarize, the distinction is that, whereas CTP considers the other components, such as labor availability, the capabilities of the corporate fleet, or how materials move through a supply chain, ATP only considers materials availability.

An instance in manufacturing is when a corporation pledges to provide a product on schedule and to specifications. This implies that the firm has the resources to deliver on its promise as well as that the organization is confident in its capacity to provide a high-quality product. When a corporation makes a CTP guarantee, it risks its reputation.

As a result, firms must only promise things that they are able to keep. Buyers and suppliers will have faith in the production process and will be certain that the firm will produce high-quality products on schedule as a result. Suppose this pack of dried fruits from ABC company is the finished product, and fruits and some ingredients are the materials needed to make this can of dried berries.

👉 Read More: What Is Least Unit Cost And Example?

Assume that the on-hand inventory of the pack of dried fruits is zero. In this scenario, ATP returns 0 since it merely examines the availability of the resource.

When you use CTP, it indicates the accessibility of both resources and materials. As a result, it calculates the availability of elements fruits and ingredients for the production of the pack of dried fruits. It also examines the number of items manufactured utilizing these resources and materials.

It also restricts the number of additional components fruits and ingredients, as well as other resources, necessary to produce more packs of dried fruits.

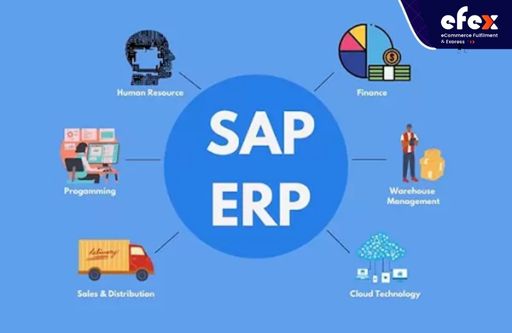

SAP’s TP method lets you set the shipping conditions for a customer order. You may use this to tell your buyer that you can ship the items within a given time limit and under particular conditions. This ensures that your consumer understands what to anticipate from you and minimizes your responsibility when something bad happens with the purchase.

It is accessible in all SAP ERP versions and may be utilized for both commodities and services. It’s simple to set up, and there are lots of internet tools to support you.

Delivery quotations are important points in managing a supply chain. According to the ATP concept, there will be times when “Make To Stock” (MTS) inventory has already been usable. This inventory must be assigned to a particular order, and a shipment time must be determined by calculating for that order.

When “Make To Order” or MTO products must be manufactured from scratch, a company must calculate how long the manufacturing process will take, considering the availability of components, resources, and materials.

👉 Read More: Order Management System: Definition, Process And Value

👉 Read More: Order Management System For Ecommerce: Definition, Key Effect, Benefit

Capable-to-promise is only one example of an enterprise solution that uses data analysis to assist organizations to address challenges. Cloud computing and other technological breakthroughs are providing organizations with advanced tools for forecasting and analyzing data, which they are employing to better serve their customers, streamline company operations, and operate at optimum efficiency.