More Helpful Content

What is the definition of excess inventory and why is having surplus inventory harmful for your business? Excess inventory is a problem that all business owners face. One of them is the high inventory holding cost. We'll go through why having too many goods on hand is harmful to your business in this article. We'll also reveal to you how to deal with overstock inventory in the most effective way possible.

Excess inventory meaning refers to a product that has not been sold yet because it exceeds the demand projected by consumers. Over-buying, wrong estimates, canceled orders, a poor economy, unexpected weather changes, uncertain customer demand, or late or early delivery of products are all common excess inventory examples of stock demand mismanagement.

An excess inventory does not occur by chance. There must be particular reasons for holding an excessive amount of inventory on hand. The top 5 reasons for having too much inventory are listed below.

The first obvious reason is that demand was not accurately predicted. Businesses estimate customer demand in a variety of techniques and strategies. However, many people use outdated and untrustworthy ways, which leads to inaccurate predictions. The market is complicated, and demand fluctuation can be high.

All elements that can impact demand must be considered in the prediction models. Without good forecasting, maintaining adequate inventory levels is difficult. You'll wind up with a lot of overstock goods, which will be quite costly.

- Read More: Order Management System: Definition, Process And Value

- Read More: Order management system for Ecommerce: Definition, Key Effect, Benefit

A variety of duties must be handled by the inventory management team. Handling transactions, purchasing, ordering, and any other sales-related operations are included. Once the management system is chaotic, inventory tracking and ordering errors will occur. Inventory management will suffer as a result of a lack of coordination between sales, buying, and customer service divisions. As a result, if the business fails to manage its processes, it may end up with inventory excess.

Although you have a well-developed inventory management system, things might still go wrong. If you wind up with too much stock, you must be prepared to deal with it in some way. It's not a good idea to assume that your obsolete inventory will sell out at some time in the future. You can't afford to overlook your slow inventory. Obsolete inventory will reduce your profits and add to your costs. As a result, ensure that a team is working to improve the inventory process and reduce excess.

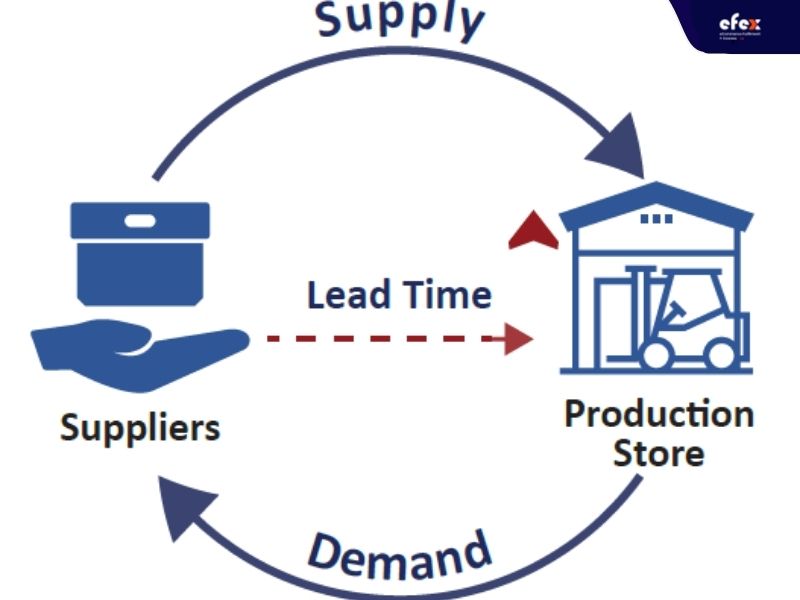

Every party involved in your supply chain, from suppliers to manufacturers, ensures that their lead times include a safety factor. They do so in order to have some additional time in case something unexpected occurs. Long lead times and an inefficient supply chain are the outcomes. It's critical that everyone involved in the supply chain process provides you with a reasonable lead-time estimate. This will help you cut lead times, improve your supply chain, and lower the amount of stock you maintain on hand permanently.

For effective inventory management, having dependable suppliers is critical. Assume you place your order early enough. Your supplier, on the other hand, retains the products for an uncertain amount of time, and your order arrives late. As a result, the next time you place an order, you'll order far more than you need to fulfill future demand. However, you run the danger of holding too much stock. That's why it's critical to engage with dependable suppliers that can fulfill requests on schedule.

Excess inventory is often thought to be harmful to the company because of the impact it has on inventory turnover and management expenses.

The following are several disadvantages to having extra inventory in your business.

The loss of revenue is one of the most serious consequences of excess inventory. Products degrade and lose their initial price over time. As a result, the longer you keep a thing, the less it costs. We're talking about mass-market items here. So you not only pay a lot of money to keep the overstock inventory, but you also sell it for a low price. Therefore, the cost of inventory isn't the only concern. Typically, businesses sell their items for less than they purchased for them. They end up losing revenue and decreasing the profit margin.

👉 Read More: LIFO – FIFO Inventory Cost Method: How To Calculate And Example

Even if you don't have to pay for storage space and lose money, keeping extra goods is difficult. Excess merchandise takes up valuable land. Because your shelves are full of outdated goods, you can't offer current products to customers. The more overburdened your storage is, the more difficult it is to keep track of stock levels. More labor hours and tougher work would be required to manage the inventory.

Specific metrics may be used to assess how efficient the product turnover is. These may be used to ensure that your inventory does not become obsolete.

As previously stated, the cost of keeping extra inventory is quite expensive. To begin with, you will require room, and having more space implies spending more money. Even if you have sufficient space and don't need to rent it, there are still costs to consider. Consider the storage's utility costs as well as any other charges that may occur.

You'll also have to hire the staff who will be in charge of inventory management. Maintaining storage space, arranging goods, and transferring it from one location to another are all part of management.

Demand is the most variable factor in the market. It is influenced by a variety of external and internal elements that are hard to forecast. As a result, the inventory you have now may not be what your consumers desire to buy tomorrow. Although demand forecasting is possible, it cannot be done with 100% accuracy. With the development of globalization, everything changes so quickly that predicting what will happen tomorrow is practically impossible.

👉 Read More: Just-in-time Inventory (JIT): How It Works And Its Advantages

As a result, the ideal strategy is to maintain appropriate inventory levels and avoid overstocking with extra items. The more inventory you have on hand, the more likely you are to lose it owing to fluctuating demand.

The worst thing that could possibly happen to your stock is for it to decay or become obsolete. Only specific sorts of items are susceptible to such scenarios. Consider food and pharmaceutical items. If you have too much of this type of goods on hand, it's likely that it may spoil. You'll have to get rid of them. You won't be able to offer them at a bargain since no one would want to buy them.

And, of course, selling bad food is the last thing you want to do. For long-term profitability, you should keep inventory levels of such items low.

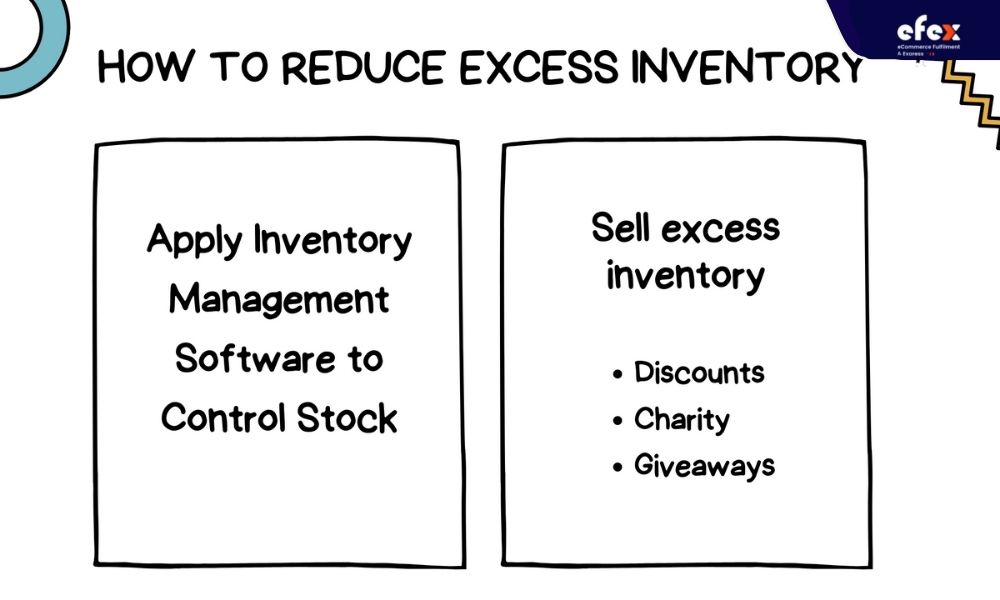

Excess inventory has so many drawbacks that may go on and on. Having too much stock causes a slew of issues that must be addressed. So, why not address the issue of surplus inventory? Business owners must make sure that everything in their company is well-organized and managed. A high inventory turnover rate is required. Here are two best ways for this case:

Adopting inventory management software to help keep inventory under control is the best method to handle the excess inventory problem. Adopting inventory management software will assist in resolving all of the issues mentioned as well as dealing with surplus inventory. You may remove all the reasons for overstocking by using the software.

👉 Read More: Real-Time Inventory Management: How It Works And Benefits

As previously stated, the failure to foresee surplus stock is the primary cause of it. You'll be able to develop more accurate predictions and track inventory levels, orders, and sales with inventory management software. It's the most effective way to avoid overstock and out-of-stock issues. Inventory management software will do the following:

In this age of technology and innovation, even small businesses should use inventory management software. It will support the organization with internal operations and the improvement of cash flow. Manual estimates are the least accurate and should be avoided.

This seems to be an obvious way that many businesses use in the case of excess inventory. Now comes the wondering part: excess inventory for sale without losing too much money. You may get rid of extra goods in your storage in a number of ways.

The most profitable option is to sell it at a discount. Original items from well-known brands are sold at low costs in an off-price store. Overstock items, seasonal items, canceled orders, and low-demand items are all purchased by off-price stores.

👉 Read More: Cost Of Lost Sales: Formula And How To Solve

When compared to the pricing of the goods in other shopping centers, they offer lower costs. You can recoup some money by selling your leftover product to off-price merchants. There is no possibility you can do excess inventory liquidation without losing money. You can, however, discover a method to sell with a small loss.

In either case, keeping the inventory would cost you more than the margin you would lose if you sold it. Here are some other strategies for attracting excess inventory buyers to deal with surplus inventory:

You can give steep discounts for excess inventory sales, depending on the goods and the reason they wound up on excess inventory shelves. It's preferable to have something than nothing.

Getting active in corporate social responsibility by donating your items to charity is a terrific approach to improve your brand image. You're not going to retain the surplus inventory anyhow, so why not donate it to raise public awareness?

This is another way that will not generate any income but will provide your brand with intangible benefits. Consider using promotions to give away things. You'll boost consumer happiness and their overall experience with your brand.

Excess inventory costs the business money and limits cash flow. Dealing with it is critical for your company's long-term success. Low turnover results to lower sales. Get rid of that excess inventory and watch your business soar!