More Helpful Content

When it comes to project management and planning, keeping track of your inventory is essential. The sap inventory aging report allows users to get up-to-the-minute aging of current in-stock levels as well as transactions particular to those products. You can set the Inventory Aging Report to show information about particular products, warehouses, issue tactics, valuation techniques, and intervals to suit the needs of your company.

Based on their relation to the reported date, specific products or warehouses may be combined or removed from these reports. So, what exactly is Inventory Aging Report SAP?

An inventory aging report in SAP is an overview of the distribution of the materials' available stock over time, starting from a key date determined and reverse in time. For an instance, a specific substance might have 100 Units in stock on a specified key date. It was possible to buy this stock in two lots of 50 & 50 between 6 and 12 months earlier and before 12 months.

👉 Read More: What Is Physical Inventory In Sap Mm? Process And Tutorial

It's possible that this substance is still in stock as a non-moving item and hasn't been used. This report intends to provide information on such stock distributions plotted over several time frames, or "buckets." The financial and procurement departments will be able to manage and plan inventories effectively by sorting and analyzing such materials. The time buckets might be for less than one year, more than one year, or anywhere in between.

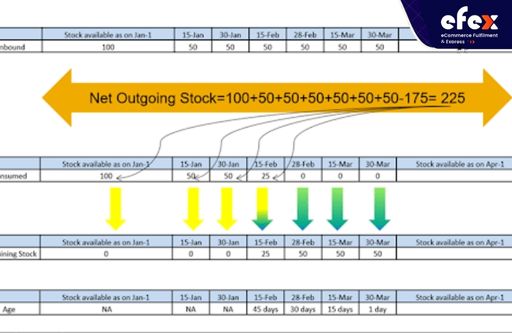

You can see how old the stock of a certain material type is by looking at the Inventory Ageing report. It is predicated on the idea that first-in, first-out (or FIFO) inventory net-off means that the materials that were received first will be used first. Details regarding the arrival and departure dates for stock items are included in the confirmation journal report.

The Confirmation Journal report is used by the Inventory Ageing report to determine how many days have passed since the materials arrived up until the present.

Once the report is run between today's date and a specific past date, such as one month, 6 months, one year, etc. Input criteria:

Once running the report between two past dates. When more information is needed for aging stock, it can be helpful. Input criteria:

An inbound confirmation is created at the receiving site whenever a stock transfer occurs. The age of moving stock at the new site is determined using new confirmations because this report is dependent on confirmations. The inventory's age of the source site isn't taken into account.

If inventory records don't correspond to the actual count during an annual or periodic inventory count, an inventory change is made. The adjustments that can be done to correct the inventory mismatch and take into account the age that ought to be given to the delta inventory are as follows:

Inventory should be modified in the inventory count since the scrapping of stock causes a decrease in stock.

The inventory aging report does not take custodial stock into account.

The report primarily engages in three activities.

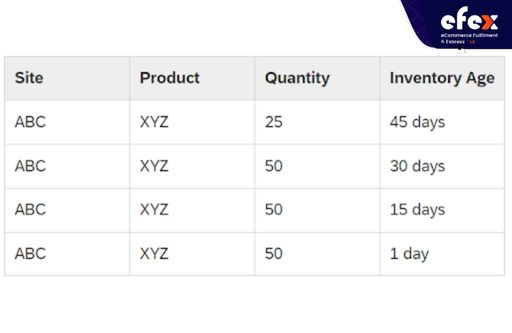

Let’s take a look at the following example to better understand the process of making an Inventory aging report in SAP!

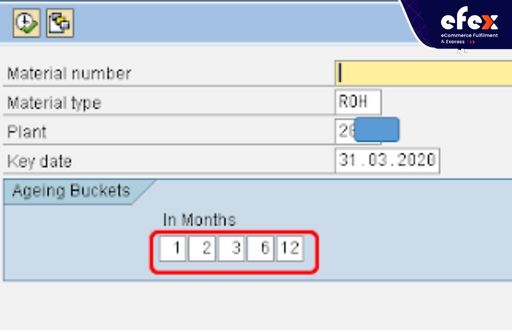

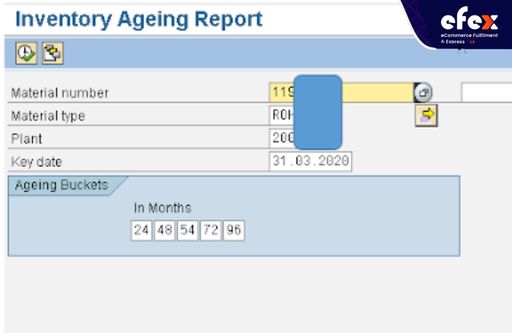

The buckets or times to be examined are represented by the fields that are enclosed in red. The buckets are adaptable and the user can alter them to suit their needs. It is advised to set the key date as the last day of the previous month and to run the report in the first week of the current month for better outcomes and practical considerations.

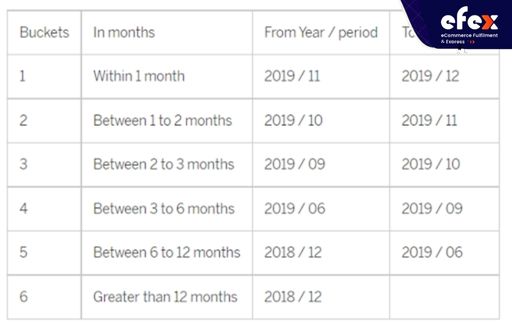

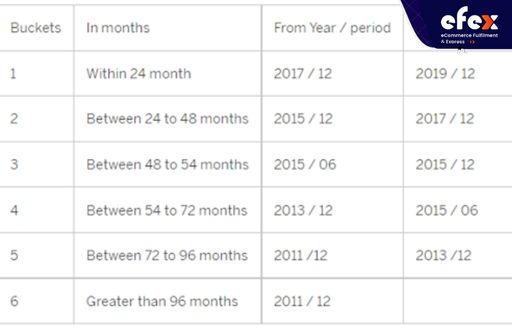

This is done in order to improve the MBEWH table's working logic, which only updates stock at the end of each month. The aging buckets that the system will automatically determine for the previously entered buckets and key date combination will look like this:

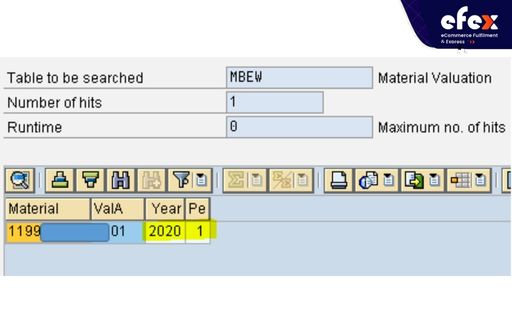

The example business code employs a fiscal year that runs from April to March. Add the fiscal year and period to the MBEW table using the material/plant (bwkey) column.

According to the MBEW, the period for the material is January 2020, while the period for the key date stated (31.03.20) is December 2019. We must take the inventory on the key date by providing the appropriate key date year/period to the MBEWH table and getting the stock from the LBKUM field if the year/period acquired in MBEW is higher than the key date year/period.

Get the inventory of the material from the LBKUM section of the MBEW table if the year or period acquired in MBEW is less than or equivalent to the year or timeframe of the key date. In this scenario, this date stock is crucial.

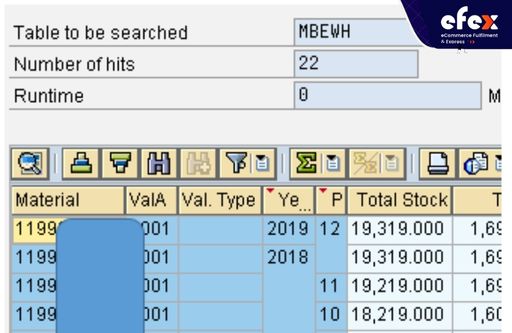

Please take note of the screenshot below.

Period 12 includes one entry for the 2019 fiscal year. There are no entries for any other times in 2019. Similar to the previous fiscal year, only the quarters of 12, 11, 10, 6, and 5 are listed for stocks.

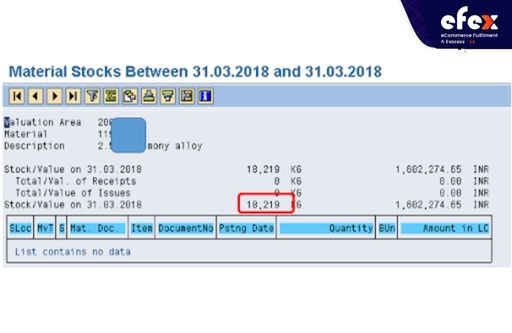

The following reasoning is used to build the stock data in the missing year or period: The stocks in the years and periods that are not listed have the same quantity as the immediately preceding, listed year or period. In the years 2017 and 2018, there are stocks for periods 10 and 12. But there aren't any details about year 11. According to the reasoning above, the inventory in period 11 is just the stock in the immediately preceding period, or period 12, which is 18,219.00.

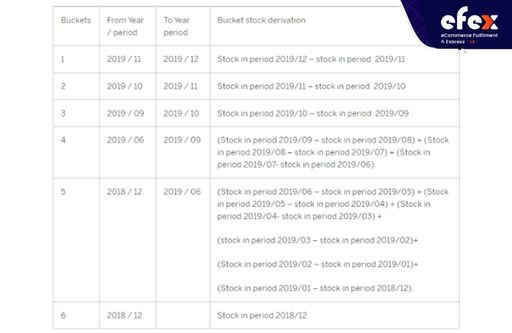

Using the reasoning below, the bucket stocks are filled.

For instance, "stock in period 2018/12" here refers to the stock at the conclusion of 2018/12. Use the common MB5B to verify the logic above. Assume that the material input bucket months are 24, 48, 54, 72, and 96.

The bucket information is as follows.

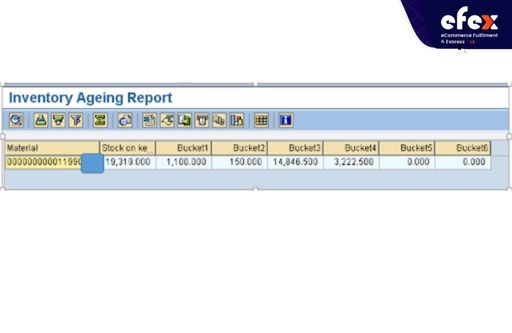

The outcome of the aging report is:

👉 Read More: What Is Goods Receipt In SAP And How To Create

👉 Read More: What Is Backflush In Sap: How To Deal With That

There may be numerous known or unknown inventory issues. The problem is exacerbated by excess, outmoded goods, just-in-case safety stockpiles, material placed in the wrong warehouse, material that is neither excellent enough to use nor good enough to be thrown away, and products that are close to expiring. These inventory issues amount to waste. They tie up money for the company, necessitate material handling, and take up valuable space.

Most crucially, inventory issues increase the size and complexity of the warehousing operation, which drives up the cost. If an appropriate aging inventory management strategy is not adopted, business organizations suffer numerous issues. Therefore, an inventory aging report SAP will be undeniably a great report for any warehousing management.