More Helpful Content

It is a vital necessity in any firm to keep the inventory ledger correct and up-to-date, which may be accomplished by doing a physical inventory of all items. This is a critical component of a company’s growth. This blog will explain the physical inventory in SAP MM, as well as the many procedures and steps that may be utilized to complete the physical inventory process based on the needs of the business.

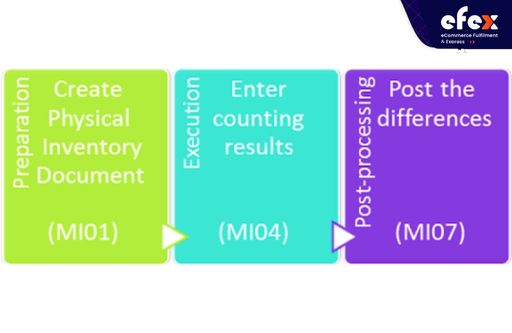

The process of determining whether or not inventory amounts are precise, or if there exist discrepancies between numbers indicated physically existing and those described in the SAP system, is known as physical inventory. Essentially, after physical inventory is completed, your system and inventory level are the same. It is mandated by law, and it is usually done once a year. You can see the below picture to see the physical inventory process. The following are the most typical procedures for performing a physical inventory.

Aside from the legal implications, having the right inventory amounts that match the actual inventory is highly beneficial. Management can obtain reliable data on the worth of stock items. ATP is proper for sales. MRP is carried out using the proper input variables (material stock quantities).

- Read More: Order Management System: Definition, Process And Value

- Read More: Order Management System For Ecommerce: Definition, Key Effect, Benefit

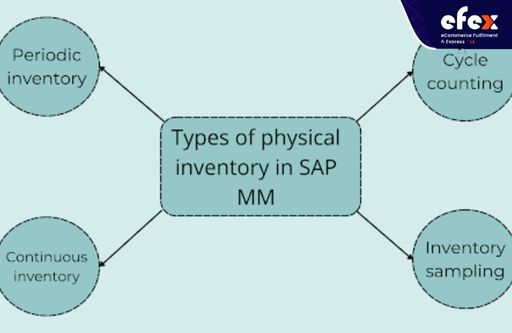

There are 4 physical inventory processes that we can use in the SAP system, including periodic inventory, continuous inventory, cycle counting, and inventory sampling.

This type of inventory is commonly used by businesses. It shows that on the balance sheet significant date, all inventories of the firm are physically tallied in a periodic inventory. Most of the time, it is done yearly and is known as the yearly physical inventory. Therefore, material inventory is tallied just once per year. It usually happens after the season has ended or when the year ends. Remember that every item must be counted in this situation and during counting, all material movements must be prohibited throughout the facility.

This indicates that all items are tallied continually throughout the fiscal year. It is critical to make sure that every substance is physically calculated at least once a year. Similar transactions can be used for “continuous inventory” as well as “periodic inventory”. The sole distinction is that a material is counted more than once every fiscal year. Besides, this inventory is mostly used in managing warehouses.

Cycle counting is a physical inventory procedure in which inventory is tallied at regular periods throughout the fiscal year. With this kind of physical inventory, we can specify a time for periodic periods for physical stock on the material level using this form of inventory. The materials’ cycle counting indication determines these intervals or cycles. Thus, a quick-moving, high-value substance can be tallied four times during the year, but a slow-moving, low-value substance can only be counted once annually.

The final one indicates that on the financial statement significant date, just a few randomly selected items are tallied, and if these substances show tiny enough discrepancies, the remaining materials can likewise be regarded to have the right inventory level. It is rarely utilized because it is simply an approximation, although it can be employed in select circumstances if the materials and warehouse system needs it.

👉 Read More: Inventory Aging Report SAP Tutorial (Step-By-Step)

After learning about the definition of the physical inventory process in SAP MM, we will continue to go through its process which is divided into stages as below.

There are two approaches to creating physical inventory records: creating single documents and creating sessions.

Consulting the following steps to understand how to create and process a physical inventory document.

Step 1:

Step 2:

Step 3, Step 4, and Step 5 are optional steps that you can do or not.

Step 3:

Step 4:

Step 5:

A physical inventory record can be modified in the following ways:

However, note that while deleting, if you enable the deleting indication for an item, it just stays in the document but will not be executed. This will free up the material. Second, if a document’s items have no stock discrepancy listings, it is physically erased. If a discrepancy has been recorded, the document serves as evidence.

As a result, it is merely marked for deleting. This indicates it can be seen but not be processed. When the following restructuring program is executed, the document is physically erased.

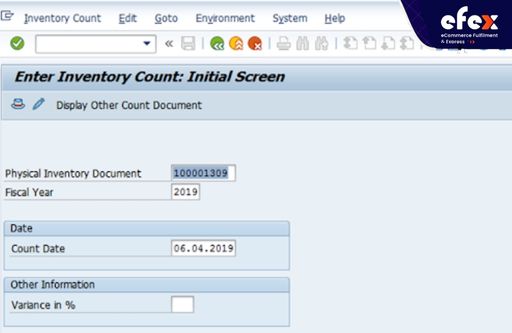

We should be able to count now that we are certain of the ingredients used in the procedure. MI04 is the T-code used for counting. The initial display looks like this, we must input the inventory number and press enter.

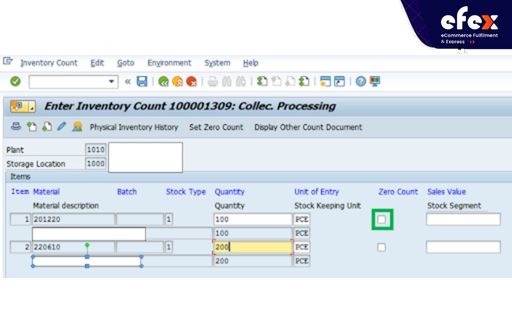

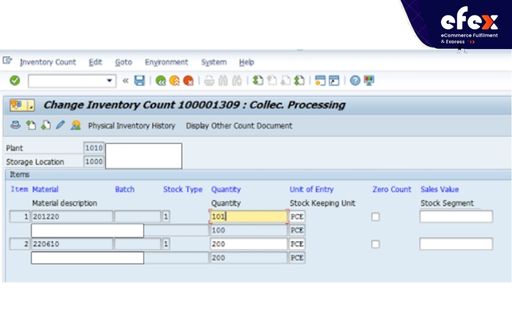

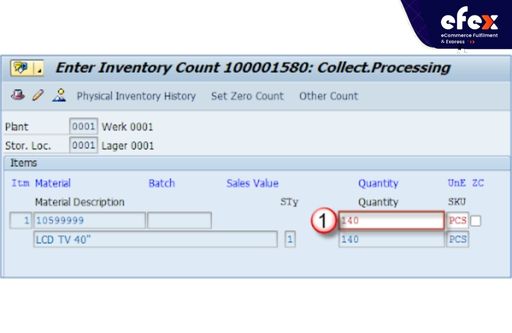

When you proceed to the following screen, you will be able to input the amount for all the materials listed in the inventory document number, as seen below.

One thing to keep in mind is that we must check the zero count indication which is highlighted in green above if we do not have any quantities to input or the quantity is zero. We will receive confirmation for the count submitted at the bottom after saving.

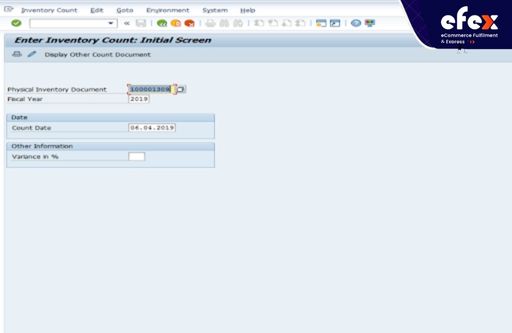

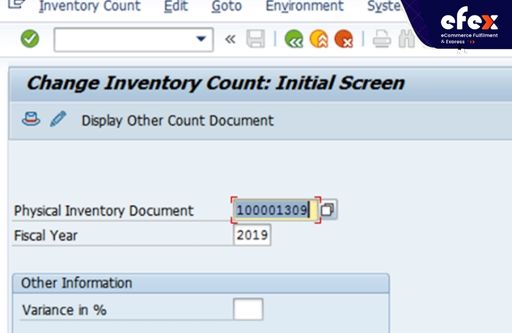

This step entails going over your already tallied inventory document number again. The T-code is MI05, and after entering the data in the opening screen, you may immediately enter the inventory document number. You will be given the inventory document number’s data and the amount field will be editable, allowing us to put our new quantity here.

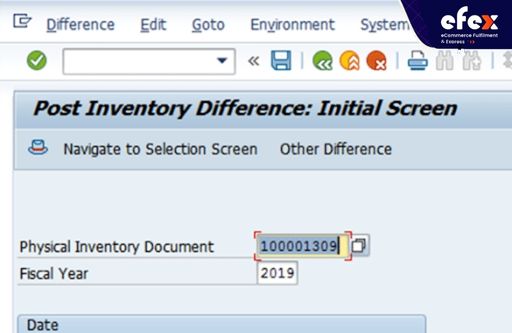

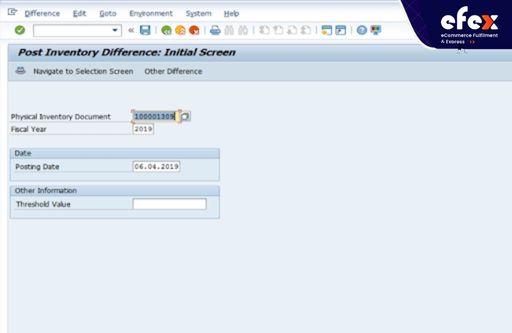

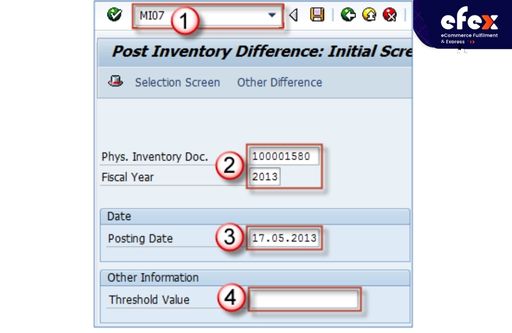

The T-code MI07 is used to clean away the disparities between the quantity tallied and the quantity existing in the system. The first screen is shown the following.

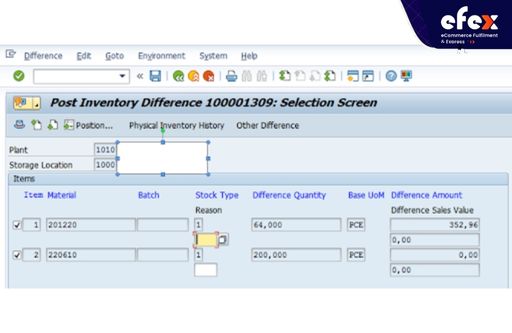

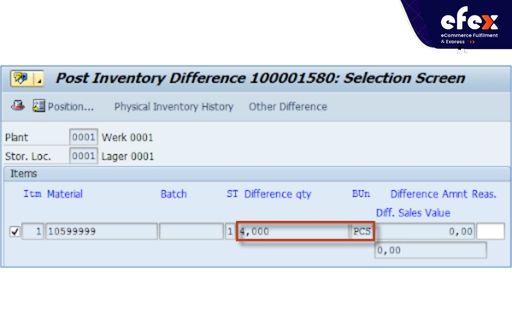

When we proceed to the following screen, we will see the discrepancy between the counted quantity and the current quantity for every material. The sales value discrepancy will also be presented in the fields to the right, as illustrated below.

This stage also allows us to see if there are any significant discrepancies or if there are any questionable materials that need to be reviewed again. So then, those materials may be rechecked. We may recheck the quantity manually. If the quantity has to be changed, we can use the T-code MI05 as previously described.

If everything checks out, we can upload the same quantity that was tallied. The tallied quantity will be posted in the back-end system at this phase. There is also a material document number associated with it.

Please keep in mind that MI07 only processes one inventory document at a time. If numerous inventory documents have to be uploaded, utilize MI37.

The method is rather simple, but it must be carried out precisely since errors in inputting the counts result in incorrect inventory balances afterward. As a result, accuracy in both the counting and entering processes is critical.

Step 1:

Step 2:

You will then be notified that there is a discrepancy in the quantity of 20 pieces. If you did not input the number incorrectly, there will be no warning when you hit the Enter key. If you input wrong the amount, you can adjust it and press Enter again. Besides, if you see the warning notice and suspect that there was an error in the process of counting, you can count the items again and fix the numbers.

Once you have correctly recounted and reentered the amount details for faulty supplies, use the transaction MI07 to submit the discrepancies.

Step 1:

Step 2:

Step 3: You can consult this step since it is optional.

👉 Read More: What Is Goods Receipt In SAP And How To Create

👉 Read More: What Is Backflush In Sap: How To Deal With That

Without reliable inventory data in SAP, a company risks losing revenue because items appear as out-of-stock when buyers need them. Through this detailed guideline, we hope you can understand clearly the physical inventory in SAP MM also its process.