More Helpful Content

Effective goods receipt operations are necessary for your business regardless of whether the receipt of the goods in the warehouse is used for production, sent directly to online customers, or even for consumption while offering services to customers.

Warehouses can receive commodities using goods receipt in SAP, including finished goods, components, finished assemblies, and raw materials. SAP goods receipt can now further streamline these procedures.

A goods receipt SAP is described as the actual transfer of products or materials through the warehouse, as well as the taking of supplies from the vendor or manufacturer and the taking of inventory from the retailer. Every positive receipt leads to more inventory being kept in the warehouse. Effective goods receipt quality is key to warehouse management for a number of reasons. It offers real-time insight into what is in your warehouse, which helps with purchasing and manufacturing planning.

- Read More: Order Management System: Definition, Process And Value

Additionally, it offers a way to make sure that incoming products are in great condition and that the business isn't spending money on useless supplies, raw materials, or components. To effectively manage inventories, proper goods receipt SAP records are also essential.

They keep a database of what should be placed in your warehouse in comparison to what is currently there, which could also immediately raise the alarm if products are missing or stolen. In the end, effective and precise goods receipt procedures help warehouses keep costs for personnel, holding costs in the warehouse, loss and shrink, as well as manufacturing delays brought on by stockouts under control.

- Read More: Order management system for Ecommerce: Definition, Key Effect, Benefit

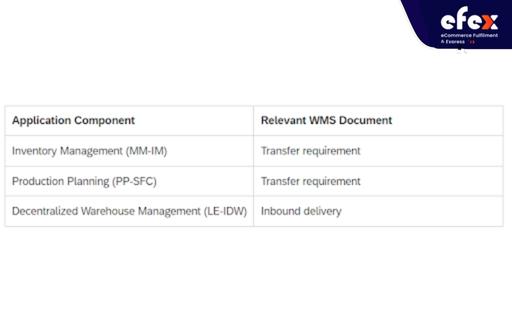

As we mentioned above, a goods receipt SAP in the WMS or Warehouse Management System involves the actual transfer of items or resources through the warehouse. It is a flow of goods with the purpose of posting items manufactured on-site or by outside suppliers. Every time a shipment is received, the amount of inventory in the warehouse grows. Many companies' transactions in various SAP parts of the system can result in a goods receipt in the WMS. The goods receipt is initiated by the matching reference document in the WMS:

The following options are available for posting a goods receipt:

The information required for generating the transferring orders is sent from the inbound delivery whether you utilize the decentralized WMS or Handling Unit Management. Whether you choose to post the product's receipt before or after the picking and packing is entirely up to you.

In order for the Warehouse Management system to create a transfer need, the receipt of the goods must first be posted in WMS for unpackaged commodities. Examples of common procedures for this include:

In this situation, you create a transfer request in the WMS and store the products first, delaying sending the receipt of the goods until after.

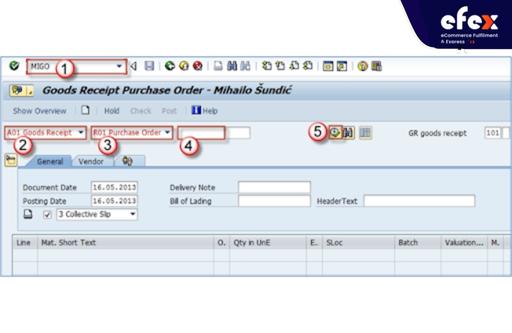

MB1C or MIGO transactions can be used to establish a goods receipt. Since MIGO is made to include all the options for all mobility scenarios, most people utilize it.

Select the posting and paper dates (it is advised to leave them both set to today as the default).

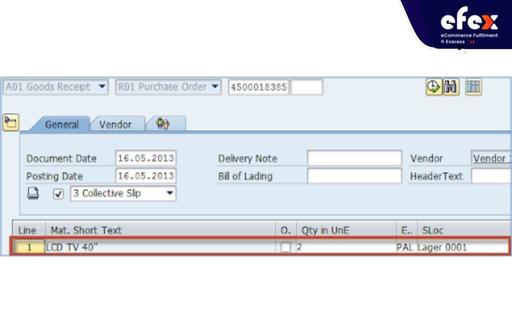

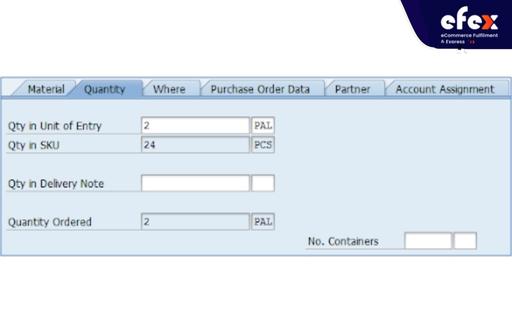

Look at the Quantity details on this tab. If you alter it, you can complete a goods receipt for much less money than the original value. The ordered quantity will still be visible at the bottom of the screen.

Information about the items' final destination can be found on the following tab.

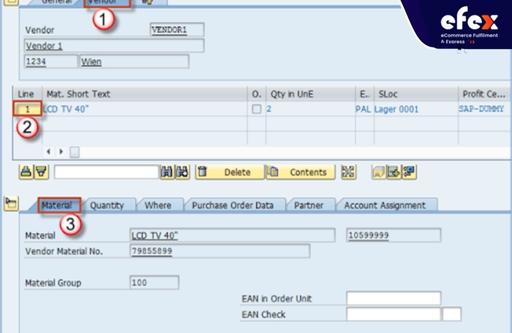

Additionally, there is information on the products' receiver and unloading location. Here, you can modify the stock post mode or alter the storage location as needed.

👉 Read More: What Is Physical Inventory In Sap Mm? Process And Tutorial

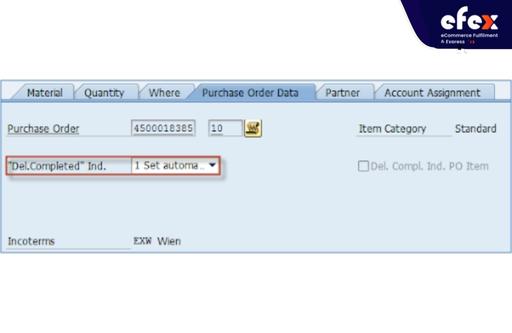

Data pertaining to purchase orders can be found on this tab.

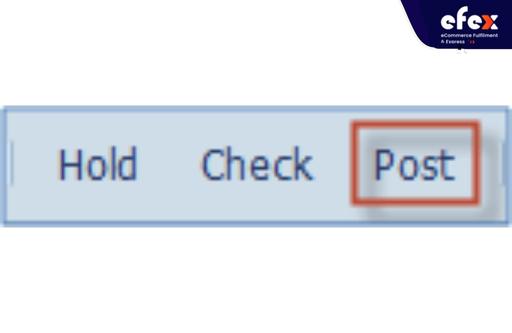

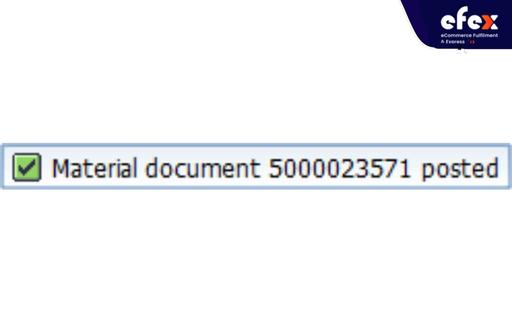

You can see that a resource document has been created once you post.

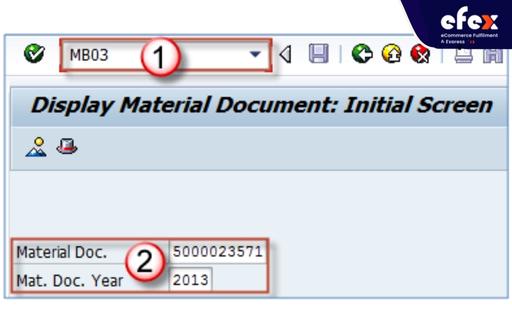

Then, you can use transaction code MB03 to verify the material document.

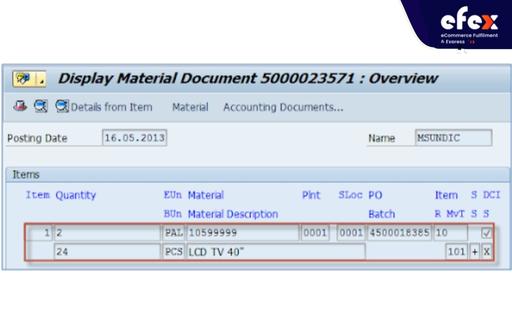

You can view some of the items and document's fundamental information. Click the item twice.

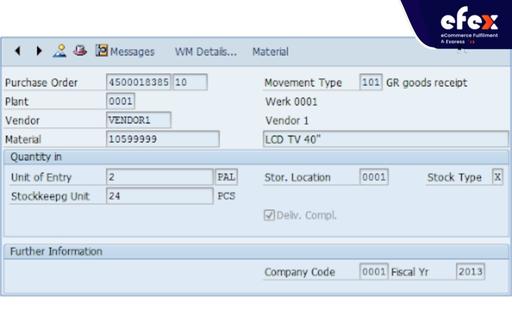

You can view some further product details in the item information.

Submitting the receipt of the goods is done. Both the production order and the inbound delivery follow the same procedure.

👉 Read More: Inventory Aging Report SAP Tutorial (Step-By-Step)

👉 Read More: What Is Backflush In Sap: How To Deal With That

Effective goods receipt in SAP procedures are essential for quality of product, loss and waste reduction, inventory visibility, and production planning. Understand more about improving your goods receipt procedures using apps created for your business. Hope you have a good time with Efex.