More Helpful Content

One of the most difficult components of running a manufacturing facility is deciding the production quantity, the time to make it, and what supplies must be needed and when. Buyer confidence is eroded when a product is not available to fulfill requests, yet having too much inventory on hand is problematic for various reasons.

In such scenarios, businesses have numerous alternatives for satisfying demand. These choices are often divided into two main strategies which are the chase strategy and the level production strategy.

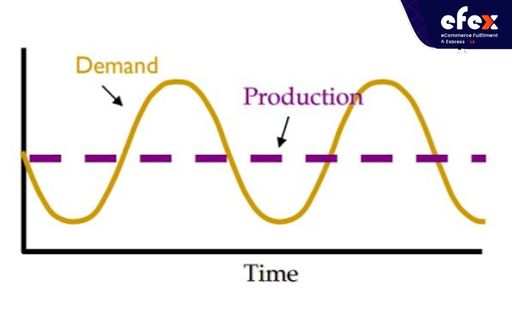

While the level production approach remains consistent regardless of demand fluctuations, the other one involves varying production in response to changes in demand.

In this article, we will go deeper into the level production strategy and learn everything about it.

Level production is a manufacturing technique in which a corporation produces a set quantity of items at a set rate. When a corporation manufactures things to suit consumer demand, it must ensure that the appropriate number of each product is available for selling at all times.

When a corporation uses a level production strategy, the Work Availability procedure is performed, but only for each particular item. This indicates that if a product is in high demand, the corporation will produce a huge number of it.

Conversely, if a product is not in great demand, just a modest number will be produced. This method is frequently employed by firms that manufacture a large number of items. As a result, we may employ this method in both the manufacturing and service areas.

👉 Read More: What is Acceptable Quality Level? Formula And Example

The level manufacturing approach focuses on producing a consistent product. Companies must first determine how much they need to generate every day and then develop a workable plan.

This plan should be adaptable enough to handle fluctuations in demand while yet allowing the company to provide a consistent output.

Like any strategy out there, the level production approach also has its benefits and drawbacks.

First, we will talk about the benefits of this strategy to see what benefits it can bring to your business.

Along with the advantages, it also has certain disadvantages that you should know if you want to use it.

👉 Read More: What Is Landed Cost: Meaning And How To Calculate It

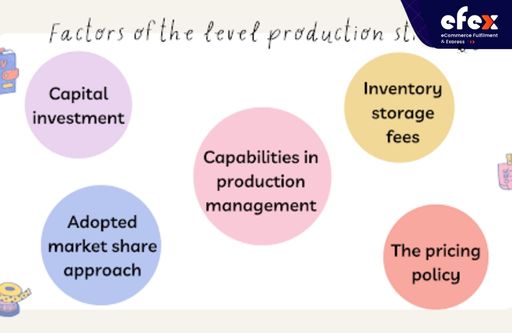

Many aspects must be considered when a manufacturing business decides whether to manufacture to stock or use a level production plan. For instance, the company must think about the following factors:

A corporation may be cautious to manufacture to stock or implement a level production approach since the extra capital necessary for the manufacturing of products in preparation may be greater than the extra capital needed if the business just manufactured if there was an actual order.

Therefore, the corporation must believe that the stock keeping expenses are lower than the extra costs of producing things ahead of time.

In some circumstances, the inventory in storage spaces and the expense of repairing damaged things might be a significant cost to the organization. The cost of replacing completed product inventory due to causes like damage or theft can be fairly substantial and must be factored in.

The company must ensure that it can create things in quality and cost-effective method. If the firm’s production warehouse is poorly managed, there is a considerable probability that it will not be possible to manufacture on time.

If management is ineffective, they may wind up manufacturing things that are destroyed during storage and are unable to recreate the item for shop shelves. It will not only lead to missed sales but will also cost the organization money in the long term due to replacement expenses and client refunds.

The business’s pricing policy will also influence their decision to manufacture to inventory or on a level manufacturing basis. A corporation that sells on price, for instance, will only want to offer a product when a consumer demands it.

In comparison, a firm that uses a flexible pricing approach would have significantly more demand since they will lower the price of their items in order to generate demand.

If a corporation is attempting to increase profits in the market by employing a low-cost approach of undercutting all rivals on price, they may want to consider implementing a flat production approach. It will ensure that the buyer’s orders are always completed at the market pricing.

Conversely, a corporation pursuing market share through distinctiveness is more likely to employ a production-to-stock approach.

Along with the above factors, the business should also be aware of the situations in which its suppliers find themselves.

For instance, if the supplier is manufacturing at full capacity and orders an extra 50% of a product that the firm has ordered. If the firm does not follow suit, the supplier will most likely bar them from future orders.

In the worst-case scenario, the supplier may refuse to take any more orders from the business.

Since capital investment is held to a minimum and fixed expenses are spread across bigger Gross Margin dollars, utilizing a level production plan allows a corporation to have reduced production costs and higher stock levels.

This method, which is similar to a sales forecast, decreases the danger of holding outmoded product inventory all year long. Profits can be expected to rise if a corporation accurately estimates the market’s demand for its goods and builds adequate inventory.

👉 Read More: What Is Universal Product Code And How To Get It

The fast food sector is a good example of adopting a level production approach. A fast food firm has a level production timeline since the demand for their products is typically strong and their gross margins are typically low. The level production method works effectively in situations of strong demand but low margins.

Another industry that commonly uses this method is hospitals that offer medical items like gloves, stethoscopes, and syringes. These goods are in high demand in hospitals, and they may be manufactured in big quantities and kept in confined locations such as below beds.

This allows the organization a lot of leeways when it comes to anticipating orders. The high expense of storage is one of the key reasons why this method is not employed by many other types of businesses.

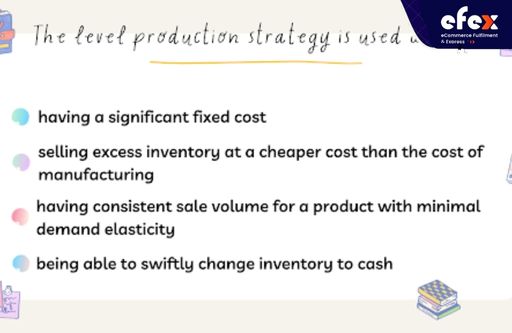

The level production method is only cost viable under certain conditions and not in many others. In the long term, the plan may harm the firm since if demand for items falls and the business has too much merchandise on hand, it may lose money. Businesses frequently use the level production approach in the following situations:

However, if the business has amassed an excessive quantity of inventory, it may discover that its estimates were incorrect and that production levels must be reduced. This drop in output must be viewed as an additional expense.

Furthermore, if the business employs higher-priced items in their product range and their inventory levels are excessively high, they may find themselves in price competition with their rivals.

If this occurs, the business’s pricing will almost certainly be reduced, as would its net income and profit levels.

On the other hand, if the business only sells goods, its expenses are almost certainly lower and it is likely to generate a profit.

Moreover, in circumstances where short manufacturing runs are used, a few extra goods in inventory can be effectively canceled out by the lower costs related to a shortened production cycle.

There are a total of 3 main inventory strategy types which are the JIT strategy, inventory strategies, and level production strategy.

The first choice that businesses must make is how they will gather, display, analyze, and share the data about their stock levels. Data on stock levels, production levels, and sales levels must be regularly examined, evaluated, and reviewed by the firm’s managers and directors.

By doing this, when supply and demand fluctuate, they may change manufacturing or sales levels to assist ease the situation.

Businesses must assess how much confidence they need to maintain in order to estimate demand and supply levels. Excessive certainty may be harmful to businesses since it wastes revenue that might otherwise be used to acquire surplus inventory. Businesses can employ standardization, modularization, JIT, and LEAN to cut inventory expenses.

While this stock reduction approaches may be utilized separately or in combination, the primary benefit of manufacturing under current Lean concepts is that they minimize the time and expense related to inventory.

This procedure entails completely removing some of the materials used in the production of the product. This is usually done whenever the real market participant is unidentified and the rival’s market share is large. Nevertheless, standardization of finished product production is carried out primarily since it is the most suited in the transference of top line income in a simultaneous given timeframe in addition to reducing costs per unit.

The key to implementing this method is the distribution department’s effectiveness in eliminating all inventory at a quicker speed and delivering items to clients who have bought and paid for them.

Buyers are willing to spend more money on standardized products since they are more reliable in terms of quality, cost less to make and distribute, are sent quickly, and seem to be better organized from the buyer’s perspective.

The materials are accessible on request in this technique, and the process includes a modulable manufacturing concept that includes the construction and installation of facilities and equipment for the manufacture of various sized modules.

The modules are produced at a cost comparable to a single unit of manufacturing, and they are then combined with the entire production line at a lower cost.

The introduction of the new product and the changes in demand are the two separate processes that are important landmarks in this technique. The use of this strategy in a company is simple, and hence, the training program is merely a question of explaining it to new employees.

When transferring work to another skilled individual, a well-trained employee may be extremely effective. This motif represents a continuous learning process that includes continual training of personnel while they complete the activity.

When the producer preserves limited inventory and the buyer offers a money option rather than holding the product when completing the purchase, the strategy by which any portion should be made accessible at the place of its utilization.

A small purchase is placed in an enormous market, and manufacturing begins only until the buyer raises the demand.

This strategy generates a lot better reaction from clients, decreases working capital needs, minimizes inventory concentrations in a single factory, and assists the organization in decreasing inventory costs by 50%.

LEAN production is essentially a collection of tactics for reducing waste in the manufacturing process. One of the reasons that explain the popularity of this manufacturing style in the industry is that it is recognized to achieve more financial and business goals all at once.

The convergence of the manufacturing process has contributed to a significant shift in the manufacturing conditions.

The world’s largest manufacturing system even may employ the LEAN production system. It has been operating for over 30 years and has assisted many different firms in the manufacturing of around 25 distinct product lines.

The LEAN production method has indeed demonstrated its notion of bringing improvements in the manufacturing process and resource management. Over the previous 10 years, LEAN has been adopted in around 1,200 different firms throughout the world, saving a whopping 1.7 million people from repetitive chores.

As a result, the LEAN production method is extremely advantageous to business operations and aids in the production of high-quality products in less time and lower cost.

👉 Read More: What Is Demand Variability And How To Reduce

The level production strategy is one in which the quantity of products generated in every period remains constant. This indicates that completed products' stock level will increase during low-demand periods and fall during strong-demand periods in businesses that manufacture to stock. This method is frequently used in combination with the chase production strategy.