More Helpful Content

It might be difficult to order the right amount of goods your business needs to meet the demand of your customers. Because either you order too much or too little inventory might cost you money and customers.

Thus, t is important to understand which inventory system corresponds to which divisions of your organization. Go through this article to gain fundamental knowledge about the P and Q inventory systems also their differences.

The fixed order quantity system or continuous review system (Q) shows that when a withdrawal is made, this system will record the remaining inventory of an item to decide if it is time to restock. These recordings are done constantly and frequently after each withdrawal. A decision about a product’s inventory position is made at each review. The system will initiate a new order if it is too low.

👉 Read More: What is Inventory Management? How Does it Work?

The overall inventory is kept between the minimum and maximum restrictions when a new shipment comes. The set order quantity approach allows for a predetermined amount of a certain item to be ordered at a specific time.

This strategy reduces ordering errors, saves space for completed product storage, and prevents wasteful expenditures, which would tie up cash that may be better used elsewhere.

The set order amount can be linked to an automated reorder point, where a certain quantity of an item is ordered when stock is on hand reaches a specific level.

Let’s take a look at the following advantages that the fixed order quantity system can bring to your business.

However, there are still disadvantages that you should consider when choosing this inventory system.

You can think about the checkbook that we use in our daily life as a simple example of a Q system. The checkbook has 300 checks. When it reaches the 200th check, and there are 100 checks left, there will be an order form for a new batch of checks.

Once this form is returned to the bank, it begins an order for a fresh batch of 300 checks. Many office inventory systems employ the reorder cards placed at the bottom of a box of pens or paper clips or among stacks of stationery so that they can know when to make a new order.

Another more advanced example of the Q system is the automated checkout system with a laser scanner used by numerous supermarkets and retail businesses. The laser scanner scans the product package’s universal product code (UPC) or bar code.

The system will quickly record and update the inventory level. Such a system is swift and precise, but it also provides management with constantly updated data on the condition of stock levels. Many suppliers and distributors of manufacturing enterprises utilize handheld laser scanners and bar code systems from managing supplies, inventory materials, equipment, finished items, and in-process parts.

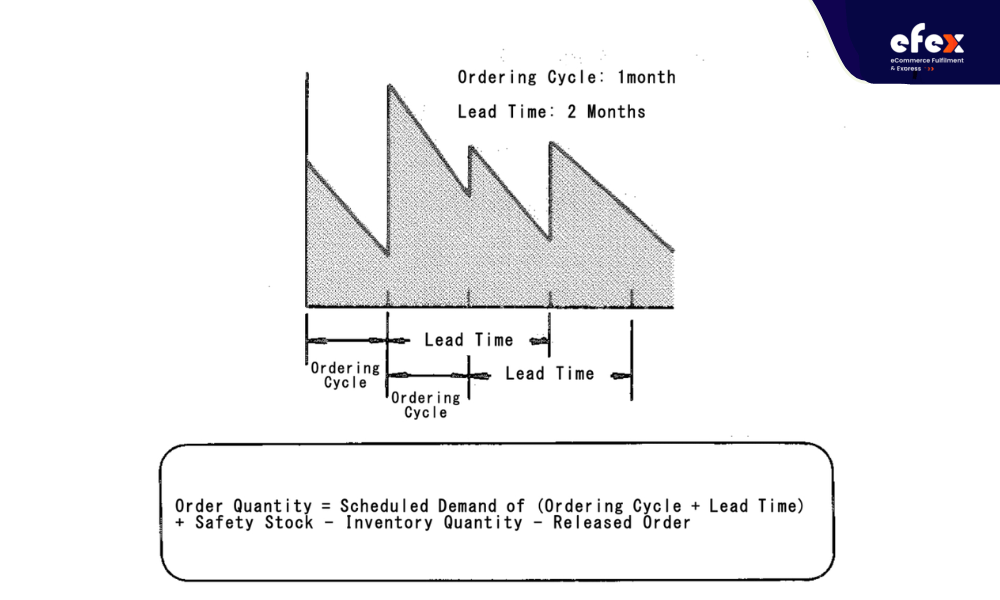

In the Fixed Order Period System (P system), the inventory position of a product is verified at regular intervals. When the quantity of a product is inadequate to maintain manufacturing until the next planned test, an order is placed to remove it.

The frequency of reviews changes depending on the company. It also changes amongst goods within the same business. The order amounts fluctuate depending on the material.

Like the Q system, the P system also has some advantages and disadvantages. Let’s consult these below benefits of the P system first.

Along with its benefits are some disadvantages but insignificant.

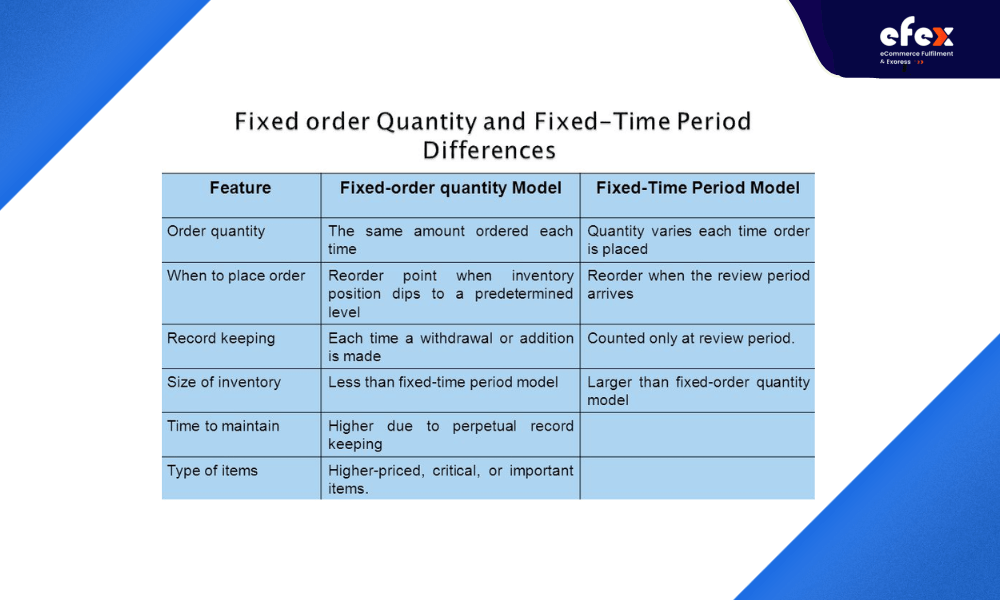

The differences between P and Q inventory systems are divided into six main features: order initiation, order period, record keeping, order quantity, inventory size, and time to maintain.

The P and Q inventory systems are used popularly by businesses in ordering inventory nowadays. Each inventory system has its benefits and drawbacks that you should consider before choosing one for your company. When your company uses the right inventory system, you will see a clear improvement in your inventory and business status.