More Helpful Content

"Quantity On Hand" is a term that is very important to a retail location or eCommerce website. This numerical value normally includes finished commodities but may also include work-in-progress (WIP) items, which are raw materials used in the manufacturing of final goods. Quantity on hand is frequently one of the primary criteria for optimizing costs in the warehouse.

The health of an eCommerce site's capacity to satisfy customer demand and, eventually, financial expectations, is reflected in how well it performs with regard to quantity on hand.

In this post, we will go through the quantity on hand and how to calculate it. Besides, we also help you to distinguish between quantity available vs. quantity on hand. Let’s dig in!

"Quantity on hand" is defined as the bare minimum of an inventory product that needs to be kept on hand in order to avoid running out before the forthcoming order.

Many techniques manage inventory based on what seems suitable rather than establishing actual figures for the quantity to maintain on hand. Inefficiency and expensive inventory costs may come from this. Determine how many goods you require so that you will not run out of resources but also don't store too many goods on the shelf when establishing minimal quantity on-hand levels for every inventory item.

👉 Read More: What Are Gross Requirements? Plan And Calculation

In order to establish the right dosages for your profession, consider the amounts consumed during a 30 to 60-day timeframe. You have the chance to cut inventory and costs if you observe that some products remain on the shelf for several months. Quick inventory turnover helps reduce overstocking and supports cost control. Reports detailing monthly medicine and supply utilization should be produced by the practice management system.

For certain products, like flea or tick preventives, change the quantities to have on hand according to the season. Setting up re-order points for each inventory item takes time, but the effort will pay off in the long run with increased productivity and cost savings. When the stock level falls to the point where the hospital would run out of the item if an order is not made, the re-order point has been reached.

For instance, you might have four cases of IV fluids on hand. If you set the reorder point at three cases, you will order another case of fluids when you are out of three cases.

👉 Read More: What Is Net Requirement? Formula And Plan

Surely, there are a lot of people who are still confused with the two different terms quantity available and quantity on hand. And here is a brief explanation for you.

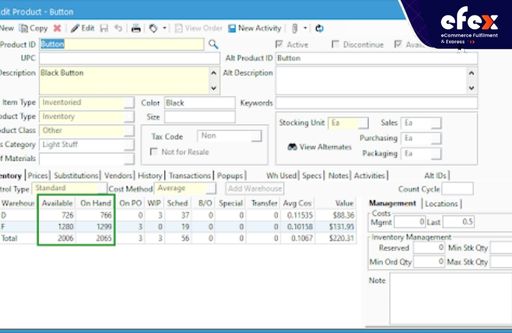

The number that is currently stocked is “On Hand”. “Available” is such On Hand minus the quantities that have been reversed throughout Acctivate for different open transactions like sales orders, transfers, and assemblies.

Quantity On Hand: This figure represents the total amount of stock you currently have, less any products that have previously been "selected" in a sales order. It also includes the quantity reserved.

Quantity Reserved is the total customer's order (the total of all open sales orders and work orders). You must achieve this number in order to finish production and sales!

👉 Read More: What Is SKU Rationalization? Process And Benefit

The reserved quantity will be subtracted from the entire quantity on hand when an order is fulfilled. The reserved amount will be added back to the sum of items on hand when an order is canceled.

Quantity Available is equal to Qty on Hand minus Qty Reserved and represents the quantity of the product that would remain after fulfilling all open sales orders.

You can view the Quantity totals for each warehouse that has been added to a product in Acctivate on the Inventory tab of the Product window. Both the Available Quantity and the On Hand Quantity are shown in this section. The totals for these values are computed differently by Acctivate.

The following calculation is the Available Quantity formula:

Available Quantity = Quantity On Hand - Quantity Reserved - Quantity Scheduled - Quantity Backordered - Quantity Assembly WIP - Quantity Transfer (+Quantity On PO*) Where,

👉 Read More: What Are Scheduled Receipts In MRP?

There are no more errors in any calculation of quantity on hand. That’s time you can figure out the minimum quantity on-hand levels for every inventory item in your warehouse to ensure that you won't run out of resources but also don't stock too many on the shelf. With our guide on how to calculate available quantities, your warehouse operation will come the right way!