More Helpful Content

A stockout is among the worst things that can occur to a company. This implies that if there is no inventory of a certain product, manufacturing must halt or a client order will not be completed. For a warehouse or inventory management, this is the worst-case situation, and it comes at a high cost to the organization. A streamlined supply chain will enable you to provide your consumers with what they want, when they want it, and avoid stockouts.

We shall explore the stockout cost, its formula also the example for stockout throughout this article.

The stockout cost refers to the lost income and expenses involved with an inventory deficit. This expense can occur in two ways:

It is not always straightforward to determine a company's stockout expenses. This is because missed sales do not display on its income statement, and the expenditures connected with last-minute purchases are typically hidden in the cost of goods sold line item.

👉 Read More: What Is A Stockout: Rate, Formula, And Risk

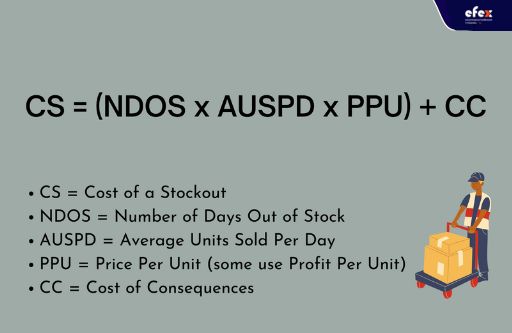

The most evident effect of stockouts is revenue loss. If a customer attempts to make an order when the product is out of stock, you forfeit the transaction. Customers may choose less expensive items. Furthermore, you may lose a buyer for good, resulting in fewer recurring purchases in the future. The following formula can be used to calculate the reason for a stockout:

Cost of Consequences normally applies only to raw material or subassembly stockouts, not completed items. Costs connected with a manufacturing line that has been idled or must be shifted over to suit another process owing to a stockout are among these repercussions. They may also include fines owed to consumers for late delivery.

Carrying costs - the disadvantage of holding additional inventory – are often estimated to be 18 – 35% of an item's worth over a year. This is equivalent to 0.05 to 0.1% every day. Though profit margins are obviously slim in this economy, making a sale is far more profitable than avoiding inventory holding expenses.

Generally, be conservative with your inventory levels. But don't get too lean. Stockouts reduce your company's income and put money in the coffers of its competitors.

👉 Read More: What is return merchandise authorization (RMA) And Process

A stockout occurs when a product that is to be utilized for a client order or a manufacturing order is not in stock once it is needed. If an item is not accessible for manufacture, it may be feasible to adjust the production schedule. However, this comes with a large expense owing to machine modifications, teardown costs, resource changes, and the time necessary in carrying out all of the changes.

If a consumer cancels their purchase owing to a stockout, they have most likely located another seller for the product. Many businesses will make sure that they have more than just one supplier for their critical commodities. Thus, ordering from the alternative may be easier than waiting for the order to be finished.

A canceled order can be costly for the vendor, not only in terms of least earnings but also in terms of the purchasing raw materials or parts that were carried in or ordered for the customer’s order. That time, obsolete, useless, or slow-moving inventory gets expensive, not just in terms of the purchase price, but also in terms of inventory carrying costs.

If a consumer does not want to wait for their purchase to be filled, they can backorder the item. As a result of the stockout, the seller will suffer certain charges. Order processing expenses rise when customer care staff adjusts the order to generate a new appropriate delivery date. Furthermore, if the transaction was part of a bigger supply and the backorder required special transportation, there may be extra shipping fees.

To increase much-needed customer satisfaction, the vendor might agree to accelerate shipment at their expense, or offer the consumer discount or free shipping on the transaction.

The worst consequence is losing a client due to a stockout, and it comes at the biggest expense to the seller. Because a client no longer places orders with vendors each order, each order represents a cost that must be assessed. If a client was a large consumer of products, the cost may be significant, putting the seller in financial jeopardy. There is also the expense of attempting to locate new consumers to fill the order that would have been made.

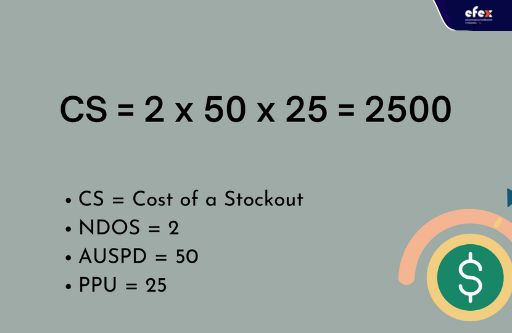

Assume you're selling a popular sweater throughout the winter holidays. You sell 50 pieces every day on average, and your profit per unit is $25. For 2 days, the sweater is out-of-stock. Based on the above formula, we have the result:

In this situation, the total cost of stock for one item is $2500. Consider the possibility of many goods running out of supply at the same time. Be aggressive when it comes to inventory levels. Don't be afraid to order more than you think you'll need, especially during peak shopping seasons. Stockouts cost you a lot and drive customers away from your competition.

👉 Read More: What Is Backflush Costing: Example, Journal Entries

👉 Read More: Probability Of Stockout - Formula And Calculation [2024]

Stockouts have a significant impact on corporate operations. Companies that encounter inventory shortages must dive into their revenues to cover extra stock and manufacturing costs, all while preparing customer satisfaction campaigns to mitigate harm. Knowing your current sales rate and target sales velocity can help you prevent stock-outs which is the first step toward making a reliable choice.

Making sure you have this information in real-time and review it frequently, preferably daily, because things move quickly in our sector and little changes in one element of the process affect everything else. In a nutshell, it is critical that businesses take safeguards to minimize stockouts cost and optimize sales the first time. Hope you have a good time with Efex.