More Helpful Content

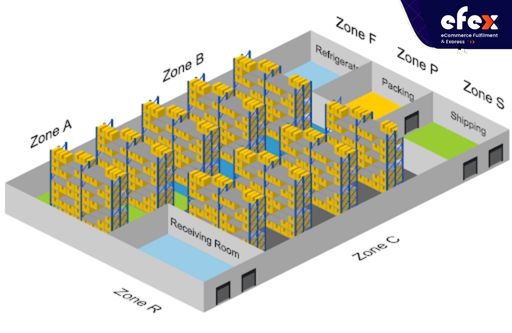

Different warehouse zones may be utilized for different reasons. If you own a big warehouse, employing zones in the warehouse allows you to differentiate between the place you want to pick your products or keep your pick, bulk, frozen, and so on. Therefore, employing zones makes it easy to get one product placed in several bins and to have default locations for picking, putting away, and refilling pick bins.

Today’s article will introduce to you the warehouse zone and types of warehouse zones that you can consult to apply to your warehouse.

A warehouse zone is a physically or intellectually separated region inside a warehouse determined by the kind of item stored or the divisions of staff and equipment employed to store, transport, and pick. This warehouse system helps to place products in precise areas so that warehouse staff knows where the products are stored. We must designate the zone in the warehouse based on the kind of product since certain items must be kept in the freezer, while others may be placed on racks or bins.

👉 Read More: What Is Contract Warehouse: Example And Benefit

👉 Read More: What Is Warehouse Slotting? Strategies And Optimization

Zone storage entails placing productions in a certain zone of a warehouse depending on the item’s attributes. There is a total of 7 types of warehouse zones, which you can see in the below part.

Products that must maintain away from water and moisture are placed in this dry zone. These locations are often kept at temperatures ranging from 50 to 70 Fahrenheit, with little to no humidity. Heating and cooling devices assist in managing the humidity levels and temperatures, preventing moisture buildup.

Products that must be kept extremely cold are placed in this zone. Foods and chemicals are examples of items. The zone typically maintains things between 38 and 50 Fahrenheit. However, some items must be kept at 0 degrees. Refrigerated zones exclusively store things that must be maintained at specific low temperatures.

Some manufacturers require chemicals as part of their production process. These chemicals should be kept in an authorized storage container.

Acids can be stored in this zone. It should be positioned separately, where corrosive things such as acids will not come into touch with other goods.

In the warehouse, gas cylinders must always be kept away. As a result, while carrying gas cylinders in the warehouse, it is required to apply safety precautions such as security chains and carts.

This zone is beneficial for certain items like goods that require more space since they will not suit standard shelves.

You can keep precious products like brand-name medications in this zone.

Below are a few tips that you can use in your warehouse as well as in developing warehouse zones.

Warehouse commodities zoning must aim to complete optimization of warehouse management. Here are major aspects to consider in its design:

The quality of each commodity will be one of the most essential factors in zoning and storing in the warehouse area. Check out the following characteristics of goods:

👉 Read More: All Cost To Rent A Warehouse In 2023

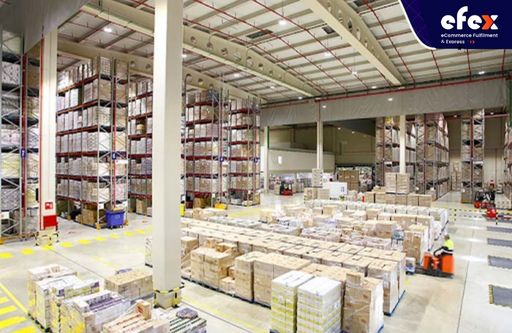

Warehouse zones aid in the organization of workflow and the assignment of relevant duties to particular locations, increasing the speed and effectiveness of operations. A warehouse’s process layout should be thoroughly examined. There are several alternatives available, but it is critical that they are appropriate for the situation.