More Helpful Content

When your goods are jumping off the shelves and there is enough stock on hand to precisely fill any order, running a business has never been more fun. What happens, though, when your SKUs begin to gather dust? Inventory that is stagnant or excessive can result in significant problems, such as rising storage costs and dwindling profit margins.

Don't worry! Inventory Aging is a practical way to avoid the pitfalls of unsold inventory and maintain your cash flow. Continue reading to discover the significance of calculating aging inventory and how this approach can improve your overall business.

Goods that haven't sold quickly or for their full retail value are referred to as aging inventory. Retailers monitor their aging inventory since, when an item reaches a certain point and is still on the shelves (6 months or more), it probably needs to be labeled down in order to make room for new stuff. In general, a brand's potential for profitability increases with the rate at which its inventory is sold through.

👉 Read More: What Is Capable-To-Promise? Specific Example

The length of time an item will be stored is determined by the inventory aging analysis. Specifically, how long a specific item quantity has been in storage. The major goal is to determine which products remain in stock for a long period or may soon become obsolete.

The session called Perform Inventory Aging Analysis allows you to carry out the inventory aging analysis. The analysis relies on the user-specified reference date, the dates of the purchases, and the dates that the item was consumed. The analysis subtraction of the item's receipt date from the specified date and time yields the storage duration for a given amount of goods.

The aggregated consumption amounts are deducted from the amount existing on the receipt date to get the product amount existing on the reference date.

The consumptions from the receipt date until the last consumption date prior to the reference date are included in the aggregated consumption amounts. After-reference date consumption is not included in the inventory aging analysis.

In order to identify inventory inefficiencies and/or lost earnings, determining the average inventory age is a crucial component of inventory management. You must be aware of your average cost of inventory, cost of goods sold (COGS), and inventory turnover ratio in order to calculate the inventory age for each of your product listings (ITR).

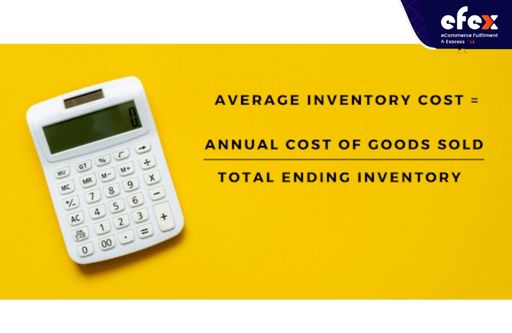

The amount (or worth) of a company's inventory during a certain time period is estimated by average inventory. An average cost estimate evens out these unexpected jumps in either way and provides as a reliable indicator of inventory valuation, smooth though inventory levels can vary dramatically based on seasonality, once delivery is received, and other factors. Use this formula to get your average inventory cost:

For online companies of all sizes, having a firm grasp on these figures may be empowering since they show if the volume of goods you're carrying is actually hurting your bottom line.

The cost of creating the commodities that a company or brand sells is referred to as the cost of goods sold. The COGS number includes costs directly associated with production (such as the cost of labor and raw materials), but it excludes a number of secondary costs (such as overhead and marketing). The following is the COGS formula:

The quantity of inventory left over from the prior period is considered the beginning inventory in this case (month, quarter, etc). Purchases throughout the Period, as the name implies, indicate the cost of the items you bought during the specified accounting period. Everything that didn't sell within that same time period makes up ending inventory.

This figure measures how frequently a business sold and replaced its inventory over a predetermined period of time (like over the course of a year, for example). Making better-educated judgments about pricing, marketing, production, and the acquisition of new inventory items can benefit ecommerce enterprises. The formula for inventory turnover is:

A slower ratio most usually denotes high sales or insufficient inventory levels, whereas a slower ratio may indicate weak sales or a significant amount of excess inventory. In either case, ITR is a crucial tool for identifying potential regions for inventory growth.

The average number of days it requires to sell off particular SKUs is reflected in your inventory's age. Because of this, analysts frequently use this metric to assess the effectiveness of a company's sales. The day's sales in inventory (DSI) term is occasionally used to refer to the average age of inventory. Use the following formula to determine the inventory age of your own products:

Generally, it’s advised that merchants corroborate this number with extra inventory measures (such as gross profit margin) (like gross profit margin).

The health and prosperity of your company depend on you utilizing the inventory aging calculation and/or an inventory aging report.

This is due to the fact that an inventory aging assessment is a potent tool created to increase the effectiveness of your storage costs, improve your inventory control method, reduce surplus inventory, and optimize cash flow all at once.

Admittedly, the expenses associated with keeping and essential for keeping don't appear to be going down anytime soon. The good news is that aging analysis can save your business money by preventing the need for long-term storage, thus enhancing cost-effectiveness. Aged inventory data gives you information on how long a product has been on hand so you may make a strategy to move it out the door.

This is especially advantageous for any brands using FBA or 3PL warehouses because both of these alternatives impose a hefty keep updating if your goods are stored on hand for an excessively extended period of time.

Monitoring the supply, storage, administration, and distribution of your product is the foundation of managing inventory. Techniques to avoid overselling, excess inventory or delays in your restocking schedule are frequently included in stock control as well as warehouse management.

Additionally, your inventory tracking strategy can be easily optimized when you combine the aforementioned methods with aging inventory estimations. This is due to the fact that an in-depth, intelligent aging study guarantees you always know exactly what you have on hand and provides the data you need to increase your inventory turnover (such as fewer expired products, obsolescence, spoilage, etc).

Products that have reached the end of their product life cycle but have not yet been sold constitute excess stock (and exceed the planned demand). Simply stated, keeping excess inventory hurts your company's bottom line. A product surplus not only indicates inefficient inventory control, but it will also undoubtedly have a negative influence on your income.

Luckily, by keeping an eye on outdated inventory, your business may stop ordering the same non-selling items and instead create a plan for getting rid of all of your dead stock. By doing this, you can create new products that will increase customer demand and your bottom line.

Since your income stream is what actually keeps your business afloat (and is what you use to buy additional things), improving your cash flow will always be a goal. There's a good probability that your inventory will have problems and that you won't be able to invest in new products if your business has too much money invested in SKUs that are no longer in demand.

Retailers may now identify precisely which products are racking up higher carrying costs or storage fees as they go unsold owing to aging inventory calculations. From that, company owners can more effectively get rid of outdated inventory to ensure an uninterrupted revenue flow.

You'll need to implement a number of applications and solutions, in addition to thorough reporting and analytics to make your inventory management strategy successful.

Finding the best inventory tools for your company will inevitably entail some trial and error, but combining inventory age has indeed been proven to help businesses in many industries.

Your business runs the risk of upsetting consumers, losing important sales, or keeping inventory that simply doesn't sell without a sound inventory management plan. However, inventory age can significantly improve your current management strategy and assist you in making pivotal decisions with your goods that could otherwise go unnoticed or unresolved.

>> Learn more: What Are The 3 Major Inventory Management Techniques?

By focusing on changes in consumer demand and purchasing habits among your customer base, demand trends can help you determine how effectively a product works. Maybe you had an item that did well in the initial half of the year following it was released, but it didn't sell nearly as many pieces in the second half.

The age of the inventory frequently indicates whether an item might succeed with a periodic promotion, a significant discount, or even being sold as part of a product bundle.

Supply chain management relies heavily on inventory planning to assist retailers to buy the correct amount of stock and decide how frequently to place reorders. Inventory age can significantly influence inventory planning because it recognizes which items don't actually need to be reordered. Similar to how inventory age offers your planning a stronger foundation, it provides you a roadmap to operate from and helps you eliminate a significant amount of the guesswork involved in this process.

Utilizing the knowledge and information you have at your disposal from inventory reporting is the foundation for making data-driven decisions on sales. With this knowledge at your hands, you can prevent making arbitrary reductions in prices or, even worse, ordering more inventory without knowing how much you currently have on hand.

Particularly for small enterprises that are just beginning their ecommerce journeys, these hasty inventory transfers can have significant long-term negative effects.

You can react to slower transactions before they turn into a serious issue if you have the appropriate tools to measure and manage aging inventory. One tool that allows you to quickly see your FIFO and identify what is aging is Inventory Planner.

Utilizing inventory aging to boost the health of your sales has three major advantages:

Fees for long-term storage can be avoided. This is advantageous when using FBA or 3PL warehouses, as they frequently charge you over a particular date range if things lie around and take up valuable storage space for an extended period of time. You don't want to give your warehouse a large number of items that won't be removed quickly and will wind up costing you more money.

Customers see brand-new products from you. Items can physically go bad depending on what you sell, especially food items with an expiration date. They might even be metaphorically worn out. Few buyers prefer to purchase clothes from previous seasons if you own a retail shop. Your inventory should have a good turnover rate.

That improves your cash flow, enabling you to invest in inventory for the quickest return on inventory investment (ROII). Not keeping cash on the shelf is in your best financial interest. You want to put new products in front of buyers from the standpoint of branding. Shoppers want to recognize they can go to you to get the latest things, therefore you should promote what you currently have to offer.

The overstock report is complemented by the inventory aging report. Consider your inventory of inactive items. What areas don't you achieve a decent ROII in? How long have the products remained unused? While overstock anticipates the conclusion of your planning period, the aging analysis provides a current snapshot of your inventory. When you combine them, you can be sure your products won't stay on the shelf for an extended period of time.

👉 Read More: What is part period balancing? Method and Example

👉 Read More: What Is Configure To Order? Example And Benefits

Even if considering products that aren't moving can be frustrating, you simply cannot afford to do so. You'll acquire a deeper understanding of your retail business and be able to change inventory as necessary by correctly calculating inventory aging once more. In the long term, you'll have more cash in your pocket and a better hold on your firm.