More Helpful Content

Inventory management across the supply chain is one of the most crucial responsibilities for organizations that deliver physical items, and it will primarily decide the business’s success or failure. The key is to always have enough stock on hand to fulfill demand while not using too much money or storage space with surplus inventory. This blog is written to provide you the answer of what are the 3 major inventory management techniques that can help you improve your inventory management.

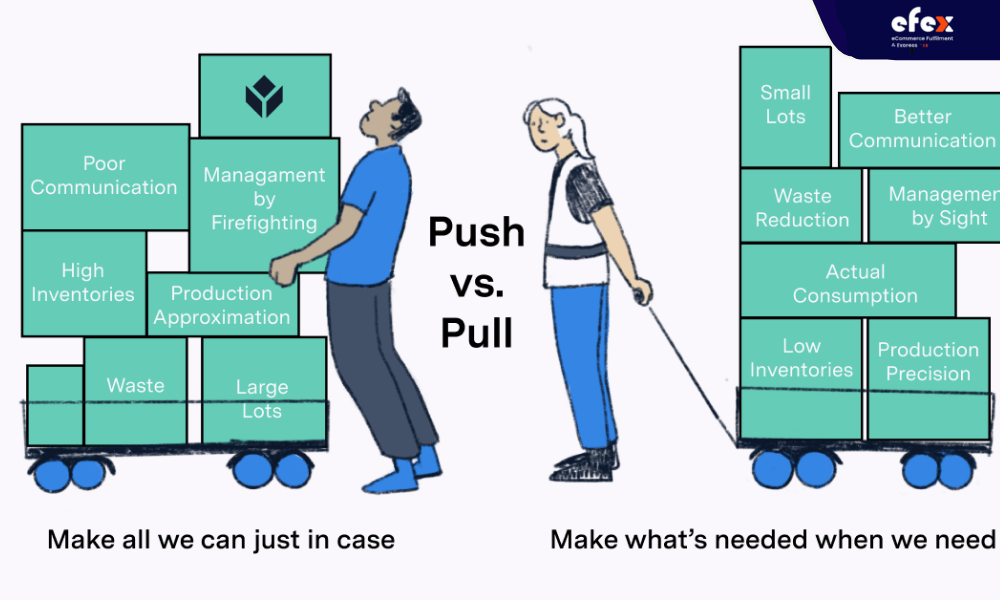

When a company uses the push technique, it releases items based on predicted or forecasted demand. Because you are developing more items at once in the push technique, it is simpler to keep operating expenses low, but there is also greater risk involved.

The push strategy is an inventory control system in which products are “pushed” down from the manufacturer to the store, company, or warehouse. A consumer or employee will then buy or utilize the product from the available inventory. A business must accurately estimate product demand to use the push strategy successfully.

Determining how much of a product is required and when it is required is critical. Using inventory software for managing supports organizations in understanding how inventory has been used over time, providing critical insights into how much inventory they may have to acquire during the fiscal year. For instance, a home renovation store may stock numerous numbers of summer clothes in the summer but only a few in the winter. These retailers will decide how many clothes to purchase depending on how many they sold in the past and when they sold them for organizations that can properly estimate client demand.

The main benefit of this strategy include long-term planning, easily available stock, economies of scale, and increased planning and control. Companies can use the push method to ensure the business has enough goods on hand to fulfill client requests and avoid the failure to fulfill consumer demand for the product. If the forecasting is accurate, the corporation may be reasonably assured that it will have enough goods to fulfill client demand. It can prevent businesses from “out of stock” situations, which could be a disaster. Moreover, it can be a component of Material Requirements Planning (MRP). This system integrates operational, financial, and logistical strategies to ensure that materials and funds are available.

However, the push system has drawbacks in the managing inventory process you should consider. Predictions are frequently inexact since sales are uncertain and fluctuate year by year. Besides, even when analytics and prior purchasing patterns are applied. Customers' demands can shift fast, and it is tough to forecast these shifts. Another trouble is that if there is too much merchandise in inventory, it raises the expense of storing these commodities for the business. Overestimation of product demand can result in difficulties such as carrying costs while underestimating can result in the requirement for urgent orders and the associated expenses. Moreover, push systems focus on order processing speeds instead of the client.

In contrast with the push technique, a company manufactures inventory depending on obvious client demand. Like other techniques, the pull method also has two sides advantages and disadvantages. Let’s learn more in the below part.

One of the three major inventory management techniques you should know is the pull practice which is in which a store, warehouse, or corporation “pulls” a product only when a buyer orders it. Customers are essentially “drawing” stuff from the brand, resulting in a two-way supply and demand street. To make it easier to understand, when a product is in high demand by customers, the brand will offer it.

The pull method is typically used for specialty products, particularly expensive commodities or items with little or unpredictable demand. For instance, many wedding dresses are “pulled” for brides-to-be only after buyers have handed over their payment cards. These ladies choose their gowns are either created or obtained for them at the time of purchase. Although it can take some weeks or months, it is an industry norm, so most consumers are fine with it.

The whole premise of the pull method in the inventory management process is to remove the possibility of excess stock and the associated carrying expenses. It is beneficial for companies who want to keep inventory expenses low. The just-in-time strategy is a common example of the pull strategy where the business has just enough inventory to meet demand. It produces a streamlined environment with more manageable inventory sizes, and it frees up room to carry a greater number of SKUs if required.

Another advantage of the pull system is that it is a more exact method based on product-level demand, which provides a more accurate view of demands.

One significant downside of the pull strategy is that a corporation is more likely to encounter ordering difficulties, such as a supplier’s inability to deliver a supply on time. As a result, the business cannot complete the order, contributing to consumer unhappiness. Another one is that unexpected surges in demand might overwhelm the supply chain’s capacity to retain inventory on hand.

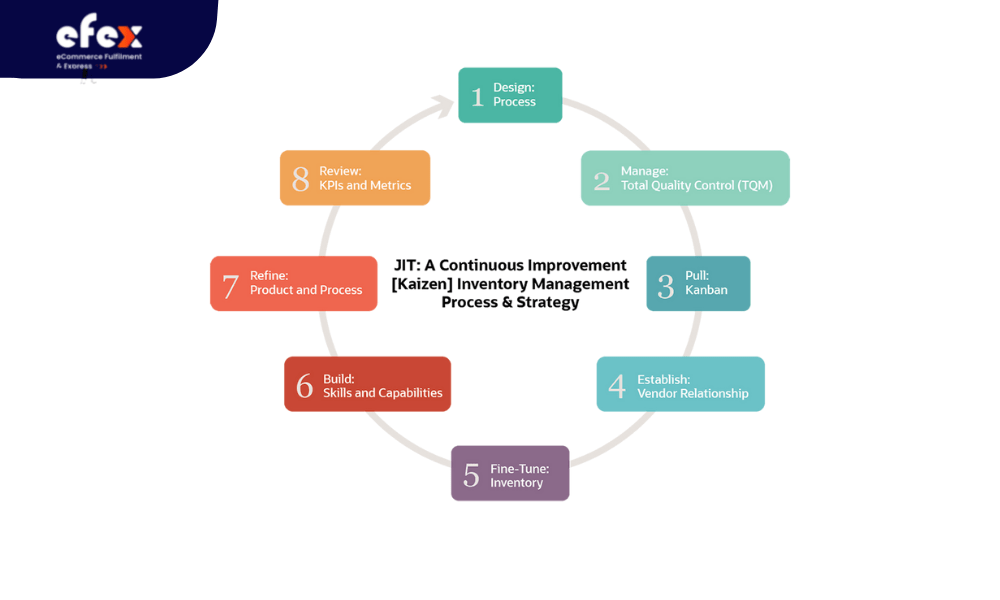

Another three major inventory management technique is JIT which demands tight collaboration with suppliers to assure that raw materials come when manufacturing is scheduled to begin but no earlier. The concept is to keep as little inventory on hand as possible to fulfill demand. Like the pull strategy, the just-in-time strategy (JIT) is that organizations purchase inventory “just in time” to meet a customer’s order or a business necessity. Adopting a just-in-time inventory management plan necessitates dependable suppliers, vendors, and third-party logistics providers. Without them, a business that may not fulfill client demands is usually a formula for disaster.

Just-in-time inventory brings many advantages to businesses: less waste, cash flow, customer service improvement, excess stock minimization, greater efficiency, and improved efficiency, which will be listed below:

It allows businesses to eliminate over-ordering and excess of all kinds of goods by reducing obsolete inventory, and deadstock and reducing defective product loss. Minimizing outdated and dead inventory reduces the danger of unsold inventory becoming obsolete in your warehouse. While reducing defective product loss helps you discover and repair defective inventory goods simpler, decreasing scrap costs.

JIT method eliminates the expenses associated with excess raw materials, excess inventory, and product storage through these ways.

The first is to raise inventory turnover ratios, leading to better inventory turnover ratios and greater efficiency.

The second one is to reduce inventory redundancy. Because of the high inventory turnover rate, things do not linger in your facility for too long and become outdated.

The third way is to reduce raw material stocks by receiving supplies in the lowest quantities possible. It can sometimes be many times per day. The last one is local sourcing. When suppliers are located close to a company’s manufacturing factory, the shorter distances help to ensure timely deliveries. Safety stock requirements are decreased when items are delivered on time and reliably.

JIT improves productivity by shortening the time and resources needed for manufacturing operations. It helps manufacturers produce products more quickly, supply new items more rapidly and easily, and implement engineering change orders to current goods easier due to having less raw material stock.

JIT practice in managing inventory can reduce bottlenecks and delays throughout the manufacturing process, which supports businesses a lot in the product flow. You can read the following benefits to understand more.

JIT strategy also helps businesses in lowering costs by receiving items on a need-to-know basis and lowering inventory expenses.

A flexible workforce can concentrate on producing high-quality goods with low fault rates, which will improve and increase customer satisfaction while decreasing manufacturing costs. With fewer things on the shop floor, employees can focus on creating high-quality products and then reduce the work-in-progress items. Because there are fewer goods on hand, accidents related to storage are reduced and less damaging. You can get quality assurance, and goods are sent directly to producing areas rather than being detained for inspection since suppliers guarantee quality in advance.

Even though the JIT technique has numerous advantages in an effective inventory management system, it still has some drawbacks in supply chain management that you should concern about. The first weakness is that the JIT inventory management strategy is strong and relies on accurate forecasting and solid connections with critical suppliers.

It is an issue when any of those fails since no backup choices are available. For example, a single supplier who cannot deliver for whatever reason might interrupt the whole supply chain and bring your operations to a standstill. Furthermore, organizations that use stringent JIT methods are unlikely to have excess stock to meet unexpected demands.

If a company’s forecasting fails to account for an increase in demand, it will not have enough stock to meet those orders. It might result in lost income and lost consumers possibly. Moreover, you should consider the potential risks when using the Just-in-time inventory management strategy. Because JIT’s philosophy shows that JIT inventory management necessitates the commitment and collaboration of everybody in a supply chain and ecosystem. If any portion of the arrangement fails, the whole system is endangered. Let’s consult the following potential risks in JIT inventory management.

After reading this blog, we hope that you've found the answer to the question of what are the 3 major inventory management techniques You should know in 2023. However, please bear in mind that choosing the most suitable inventory management strategy for your business is most likely determined by what you provide customers.