More Helpful Content

Inventory warehousing and distribution to clients may be a difficult task. Products must not only be delivered on time but they must also be housed and packed effectively. Customers' increasing needs have prompted the development of a warehouse inventory management system. These software packages reduce the workload of labor required to execute tasks and gather information, making decision-making easier.

Yet, there are several approaches to achieve your objectives if you're just starting up with inventory control techniques. To keep track of all items and their information, for example, you may start with a warehouse management system excel.

Learn how to utilize our free warehouse management system excel by reading this post. Now let’s move to the overall warehouse management system excel template:

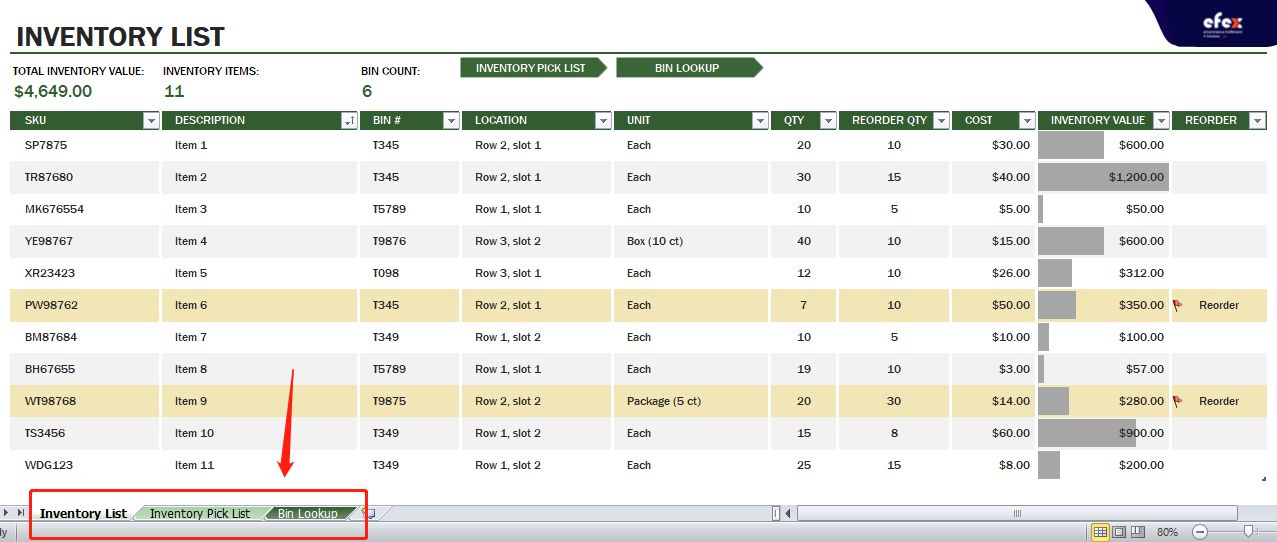

We will need 3 sheets as follows:

Then, we will explain each sheet in-depth in the next parts so that you can immediately utilize this template for your business once you download it.

Step 1: Entering data

Obviously, the forms can be tailored to your company's specific needs, such as the number of SKUs, respective weights and dimensions, and the product's expiry date.

👉 Read More: All Cost To Rent A Warehouse In 2023

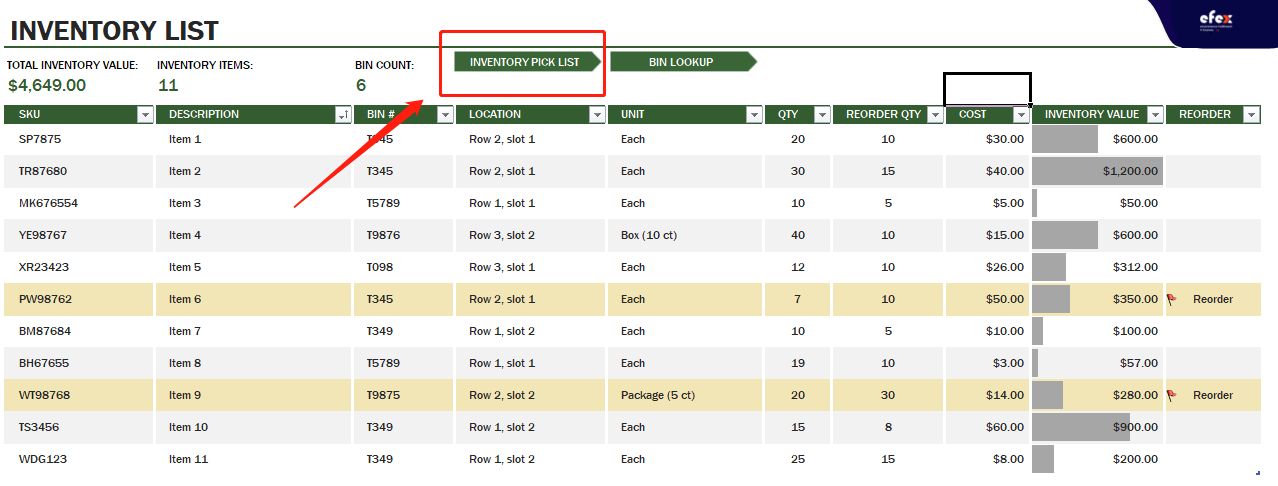

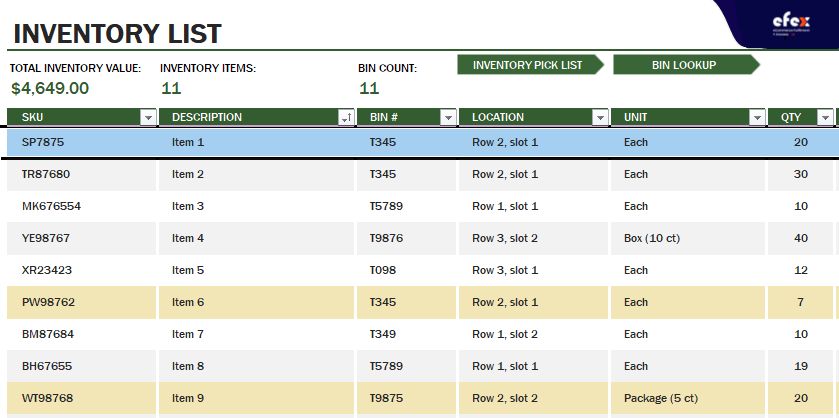

In your warehouse inventory list, you should include the following columns:

In which, there will be some things you need to note: All SKUs must be different from each one Inventory = Cost * Quantity Reorder column will be marked when Quantity equals to or less than Reorder Quantity. The formula for Reorder is shown below: =IFERROR(IF([@QTY]<=[@[REORDER QTY]],1,0),0)

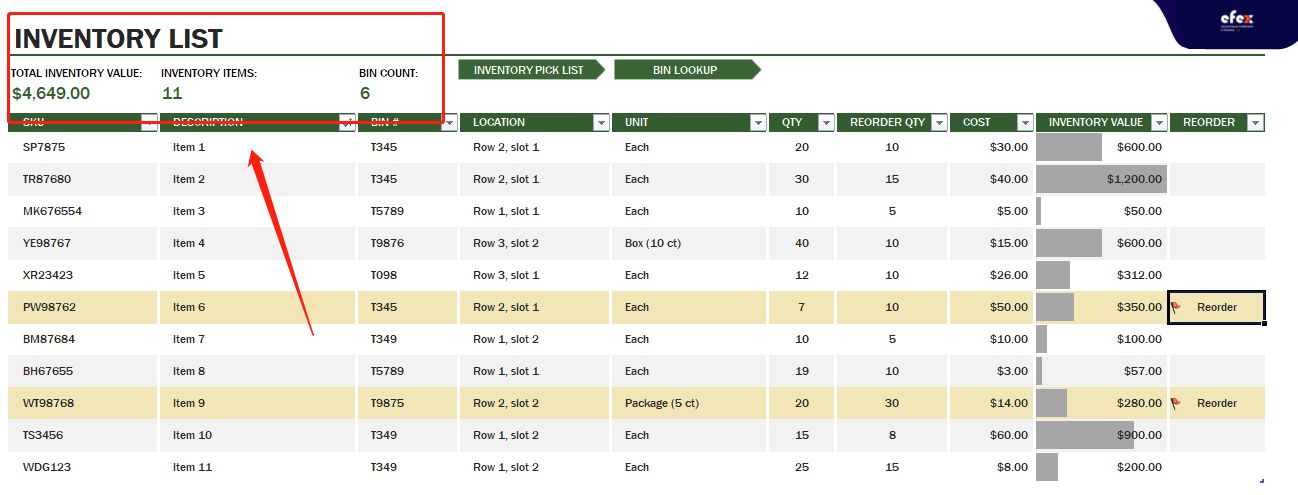

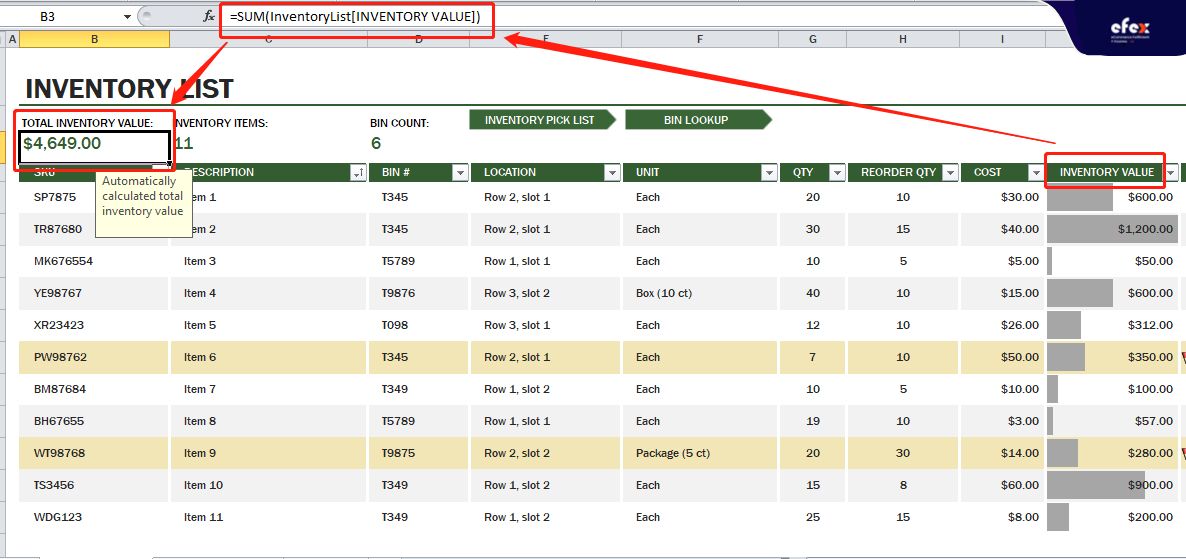

Step 2: Calculate the total When all data has entered the sheet, it’s time to calculate the total figures.

Total inventory value =SUM(InventoryList[INVENTORY VALUE]). This calculation means the inventory value in total will be equal to the sum value picked from the column of inventory value.

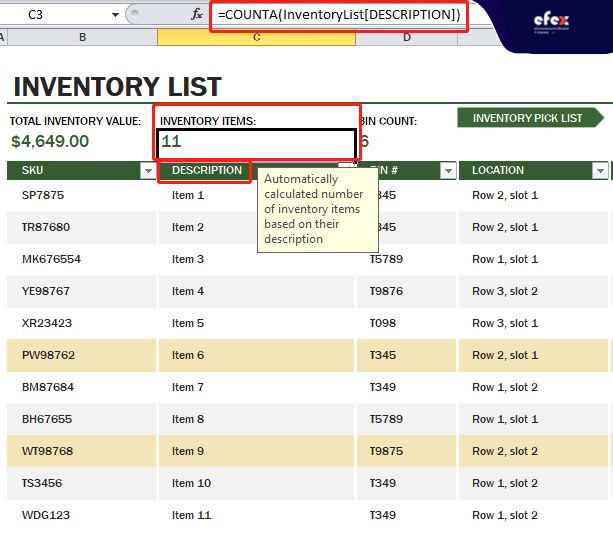

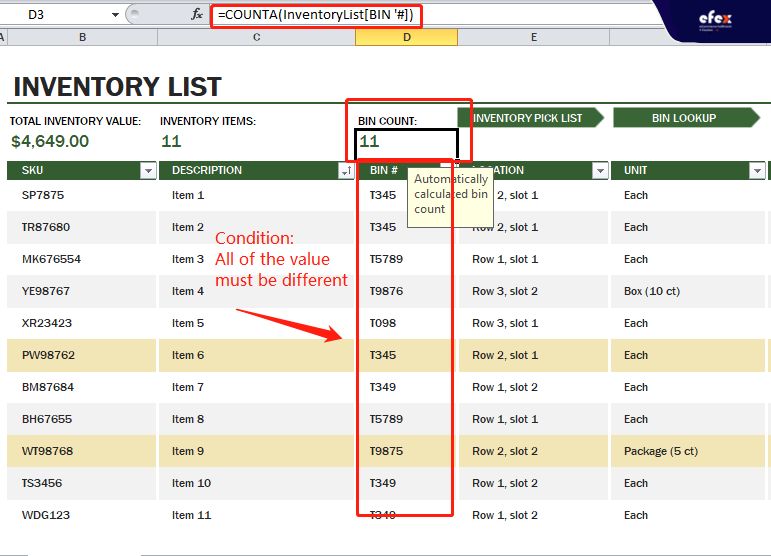

Likewise, to count inventory items, we use the COUNTA function with the formulas as follows: =COUNTA(InventoryList[DESCRIPTION])

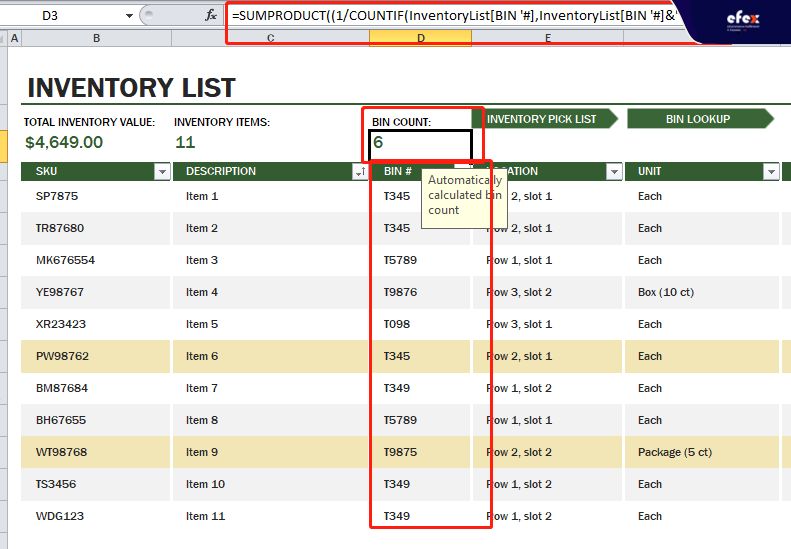

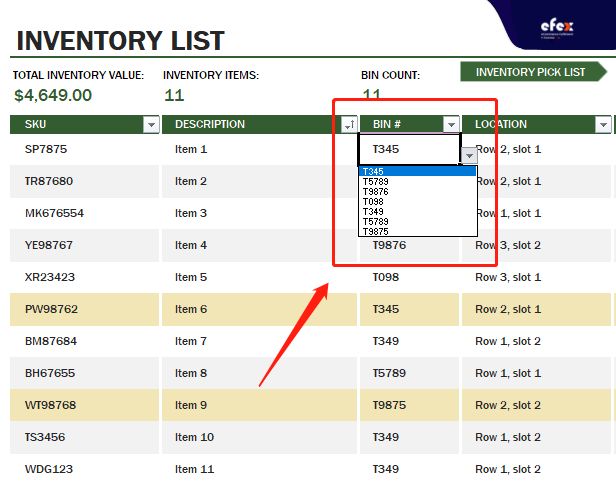

Finally, with Bin Count, the calculation will be: =SUMPRODUCT((1/COUNTIF(InventoryList[BIN '#],InventoryList[BIN '#]&"")))

Bin Because there will be the same Bins, this function will help remove the duplicate Bins and count the actual Bins in the whole inventory. Or if all Bins in your warehouse are totally different, just put them into the formulas: =COUNTA(InventoryList[BIN '#])

All bins are Now, let’s move to the next sheet: The Inventory Picking list just by clicking this button:

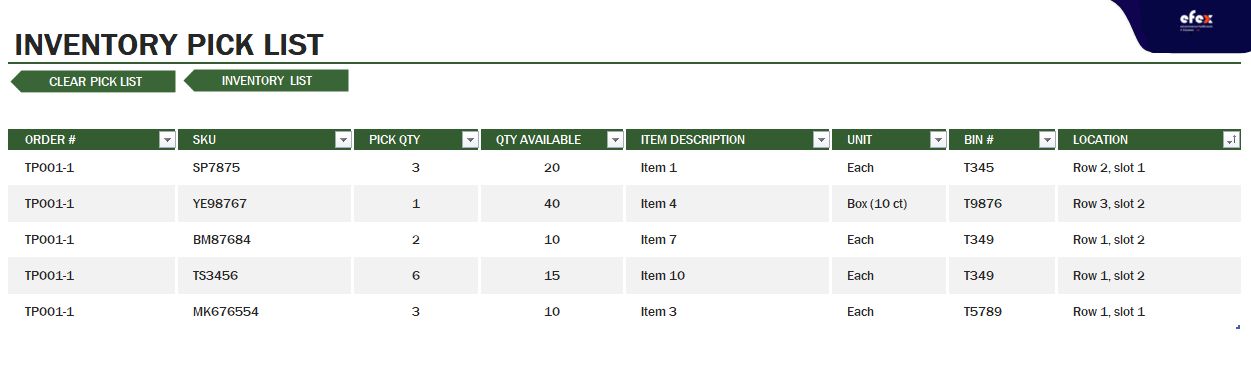

Here you can see the template of this sheet Inventory Picking List[/caption] The elements required for this phase include:

Inventory Picking List[/caption] The elements required for this phase include:

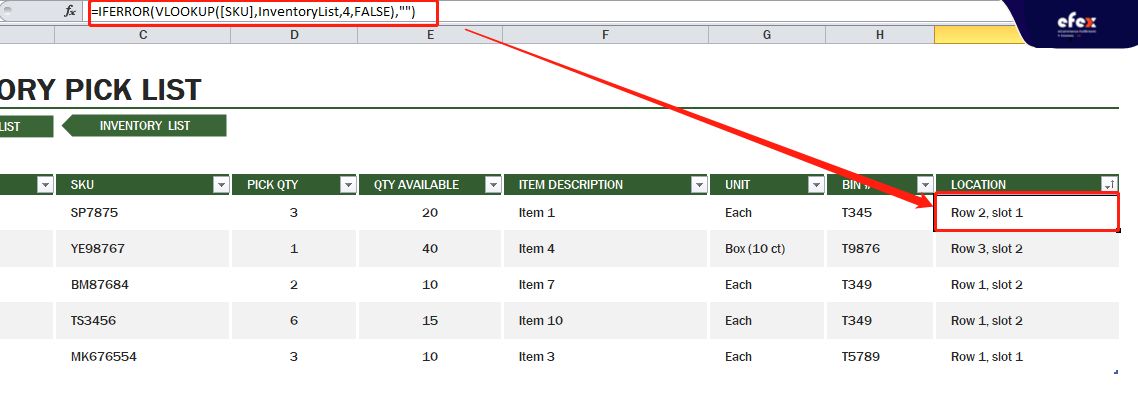

We need to enter the information of Order#, SKU, and Pick Quantity. For other elements, we will look for their value from the sheet Inventory List. In detail, we have:

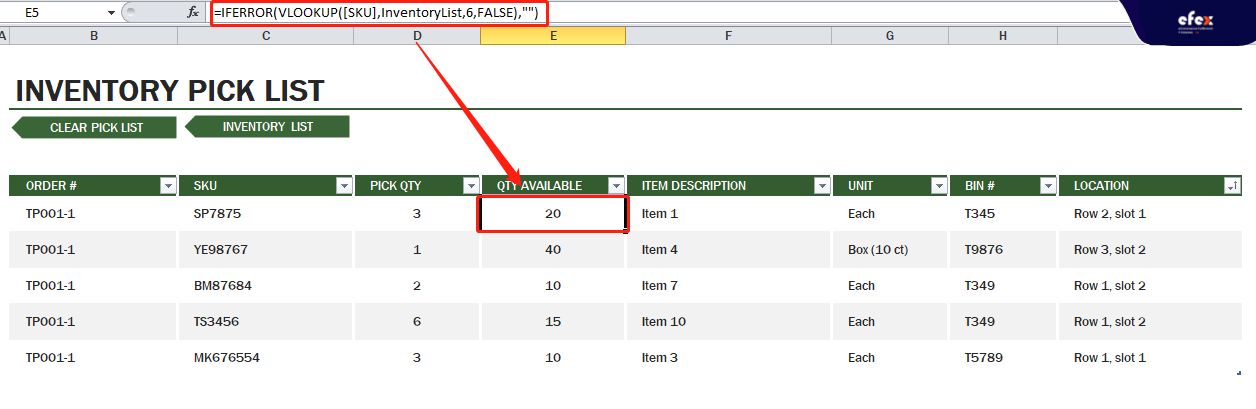

=IFERROR(VLOOKUP([SKU],InventoryList,6,FALSE),"") As you can see, we will base on the SKU value to look up the quantity available from the Inventory List. For the SKU of SP7875, the quantity available in the inventory is 20 each

- Read More: Objectives of warehouse: Definition and how to optimize

- Read More: Top 10 3PL Warehouse Management Software

- Read More: 3PL Warehouse Management System: Meaning and Benefits

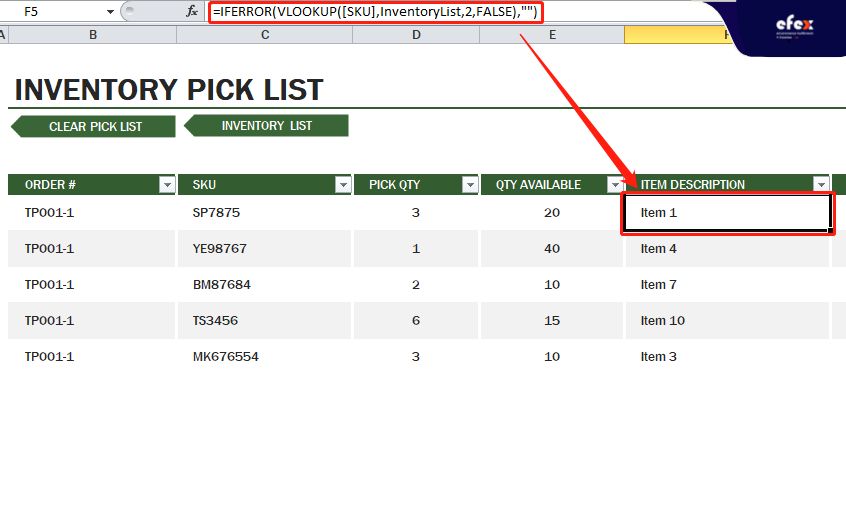

Similarly to Quality Available, we can look up Item description based on SKU entered with the formulas: =IFERROR(VLOOKUP([SKU],InventoryList,2,FALSE),"")

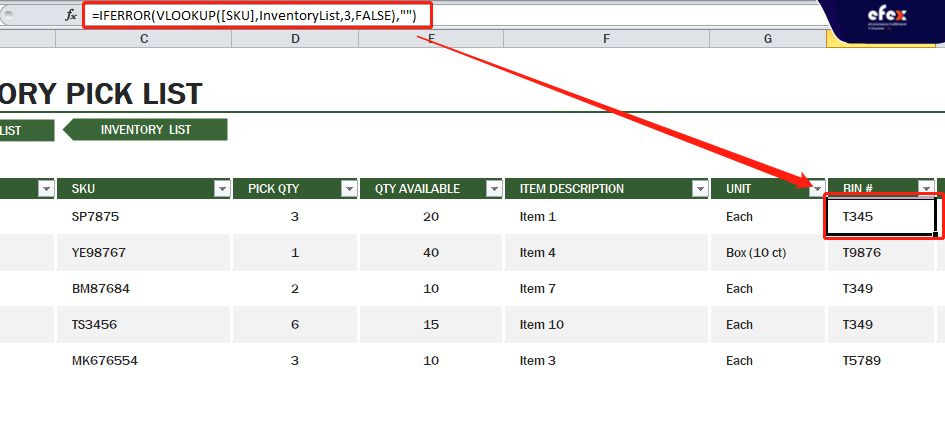

=IFERROR(VLOOKUP([SKU],InventoryList,3,FALSE),"")

=IFERROR(VLOOKUP([SKU],InventoryList,4,FALSE),"")

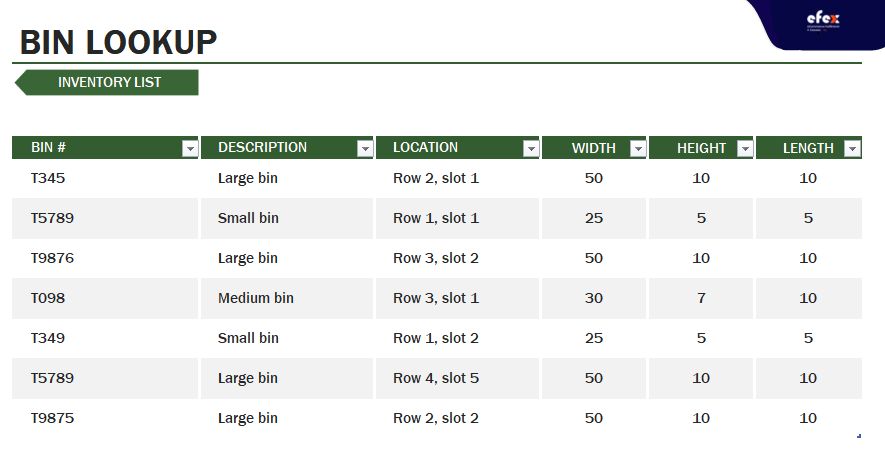

We’ve arrived at the final phase: Bin Lookup Any company will have some specific Bins which are fixed with the quantity given at the beginning. In our template, there are 6 bins with fixed specifications:

All information in this sheet is fixed! With the information from Bin Lookup, we now can create a drop-box in the Bin# column of the Inventory list.

👉 Read More: How To Arrange Stock In A Warehouse More Efficiently

👉 Read More: How Long Does It Take To Build A Warehouse In 2023?

Handling inventory with the warehouse management system excel has the benefit of being simple since many employees have become familiar with its layout from previous uses outside of logistics. Nonetheless, it's critical not to overlook some significant disadvantages. Warehouse inventory management system excel requires the manual control of a significant portion of the operation where people have to enter the data into the sheet or change them in another one.

There's a risk that you'll make a mistake.

Furthermore, Excel does not allow you to automate shipping as well as receiving or sync data with customers and suppliers. Order preparation will be also poor, and product traceability will be almost non-existent. Overall, maintaining inventory in Excel will become hard as the warehouse expands.

In this case, deploying a warehouse inventory management solution that is tailored to your large business will be a great choice. You can outsource daily tasks with the confidence that computers will handle the numbers. Using modern methods like these also minimizes overwhelm, which is a typical risk in high-traffic areas. Use the correct software to improve your company's performance.