More Helpful Content

There are several questions to consider when you think about improving inventory management for your online business. For instance, how do you handle inventory management in your company? What difficulties did you face and how did you handle them? What are eCommerce inventory management strategies you can implement?

Indeed, understanding the ins and outs of eCommerce inventory management is essential for building a long-term, profitable, and sustainable e-commerce business. Poor inventory management may well be a difficult problem to overcome for any e-commerce business. But don’t worry! All of your questions above will be answered in this article!

Any business's backbone is intelligent inventory management. It works to support both the back-end and front-end of your business. It's an important aspect of the supply chain on the backend, typically functioning as a go-between for your suppliers and customers. It keeps your statistics correct on the front-end, for example, you don't miss customers because of inaccurate data. The process of tracking the place, quantity, pricing, and mixing of inventory available from your company is known as e-commerce inventory management. The e-commerce part takes into account the requirements of an online retailer that will need to track inventories across numerous online sales channels.

👉 Read More: Top 15 Ecommerce Inventory Management Software In 2023

You should evaluate your company's needs to determine the most suitable e-commerce inventory management solution before searching and implementing Why? The reason is that inventory management affects almost every area of your company's operations.

Firstly, it gives insight into inventory levels and locations from the time of entering your warehouse until it hits your customer. Commodities that are out of stock, overstocked, understocked, or missing can be seen more easily. You can better estimate inventory purchases and plan for any shortages with this level of visibility.

Interrupted inventory management can be quite harmful to your company if customers don't take their items when they expect them, or if you sell things at a price you can't fulfill, you're harming the relationship you're trying to develop with your suppliers and customers. Fixing inventory management mistakes may be expensive for organizations, in terms of the lost sales revenue and dead stock. If you implement your inventory management approach in the right way, your company will benefit from increased buying intelligence as well as a better grasp of where your products are in their lifetime.

Consider how long it has taken warehouse staff to learn about a purchase, identify in which the goods in the order were held, and pack the order for delivery before the digital revolution. Labor hours in the past can now stay digitally, as long as your inventory control is good. Warehouses can face problems if their systems have errors or if stock isn't properly accounted for. You'll save time and gain more value from your staff if you use an effective inventory control system.

Some firms may be able to get by with a single warehouse and one product, but those who are bigger or expect exponential development should have a strategy in place about when they add inventory to their catalog. When firms choose numerous warehouses, the complexity multiplies tenfold, especially when cross-border transport is involved. An e-commerce inventory management system shows you where each commodity is located and notifies you when stock levels are low. Besides, an inventory management system also includes deep visibility into different warehouses, making it much easier than ever to manage facilities close by or far away.

If an item appears to be in stock on your e-commerce website but is later discovered to be unavailable, the shopper will have a disconnected user experience. The more precise your stock control is, the better you'll be able to meet client expectations for product availability. This is especially true for multi-channel e-commerce inventory management. It's essential to understand your inventory's total count, as well as how that number changes when orders are placed across networks in real-time.

While having insufficient inventory can be an issue, having an abundance of the merchandise increases the risk of selling it all ineffectively. Reporting provides users with information to help them make intelligent purchasing decisions, and minimize the occurrence of deadstock and wasteful inventory. Thus, they are more competent and ready than with a handwritten spreadsheet to make appropriate reorder options based on the data given.

A buyer frequently wishes to be back to an online store and buy the same thing. In terms of user experience, efficient inventory management combined with your e-commerce platform's invoicing and user account features allows users to quickly access their previous orders and re-order what they want. Ecommerce stores can simply establish mail and marketing campaigns that focus on product repurchasing when they work with email marketing partners.

At some period, each online business owner will face warehouse/ inventory management for e-commerce problems. The difference between good inventory management and an excellent one is understanding what some of these difficulties are ahead of time as well as how to overcome them. Below are several typical inventory challenges which can have an impact on an e-commerce business's profitability and growth, as also customer experience and loyalty:

It's possible to get into problems in e-commerce where you can't fulfill needs or overestimate how much stock you actually need available in a specific month if you don't have a strong grasp on your stock and the buyer's behavior. While having a big stock of inventory available might be beneficial, especially as you enter a busy season, it can also create certain challenges:

On the other hand, failing to keep a careful eye on your inventory will lead to unwanted overselling. That is, causing customers to purchase items that are unavailable. Once you oversell an item, you create problems with customer service and reputation that can take a long time to resolve. When mentioning dealing with e-commerce brands, consumers nowadays demand transparency. They would like to fully trust whether you make the commitment. When you oversell goods, you run a high risk of delaying the delivery and losing the trust you've earned with your customers. A straightforward answer for this is to label inventory as in stock or unavailable on the website so that customers can view the in-stock quantities for themselves.

Scalability is also another inventory management problem that many online businesses encounter. It's fairly easy tempting to manually manage and fulfill orders, even including numerous channels, when you're just starting out with your e-commerce operation. Nevertheless, as you strive to scale your company to satisfy the increasing demands of your client base, it will be much more challenging. Scaling involves operating on one more channel like Amazon, eBay, Etsy, or Alibaba.

It moreover includes collaborating with a variety of vendors, distributors, and manufacturers, and even involve keeping inventory in a variety of different warehouses across the country. When you depend exclusively on manual management approaches, making such attempts to develop your e-commerce business in this method is nearly impossible. When using manual control, you run the risk of making data errors that have an impact on inventory management. For instance, it might lead to an overestimation or underestimation of client inventories.

The following are some instances of poor manual inventory management processes:

It's appealing to monitor and manage inventory manually when you're just beginning operating in e-commerce to save costs. However, to prevent and adapt to some of the issues outlined above, you should investigate and develop plans to implement more scalable inventory management procedures, methods, and technologies that will support long-term growth.

As product demand grows leading to inventory control becoming more complicated, online businesses encounter another typical issue: lack of visibility. There are two major visibility issues that can wreak havoc on your ability to fulfill demand and expand your company:

Since your e-commerce business expands, you'll most probably determine to market your goods through several channels such as Amazon, eBay, Etsy, etc. The challenge is that, if you do not utilize an inventory control software (even free or paid software) keeping track of the orders from each channel, as well as how those orders affect the inventory, may be difficult.

Once your company grows, it will be possible to work with new suppliers and warehouses to satisfy your customers' increasing demands. When demand spikes unexpectedly, you want to have the product on hand and ready to go. Trying to keep track of sales, inventory, and contacts across all warehouses, partners, and manufacturers without inventory control software in place may be a bewildering task for anyone.

It's hard to know which choices need to be given and when they need to be addressed to keep increasing sales and satisfying consumer demand without total visibility over your entire inventory management system. Furthermore bear in mind that, although certain customers prefer one platform to another, they must have the same experience as customers who purchase on other platforms. This necessitates contact and engagement across several channels to ensure consistency in your brand experience, such as product and price availability.

The absence of data insights is the ultimate business inventory management difficulty when it comes to inventory management. You must get concerned with data in order to build your company and make decisions that help demand. In order to increase profits, expand capacity, and meet the needs of your customers, You should indeed comprehend:

To capitalize on or completely grasp a new chance, you often have to be able to obtain and operate inventory data in a day or even a few hours. It's nearly hard to use data to make these kinds of informed business decisions without a centralized system that gathers product details from every source in real-time, 24 hours a day, seven days a week.

There isn't a unique approach for online inventory management. Each organization has its own set of requirements, necessitating the use of diverse inventory management systems. Consider the following choices to see which one best fits your business strategy.

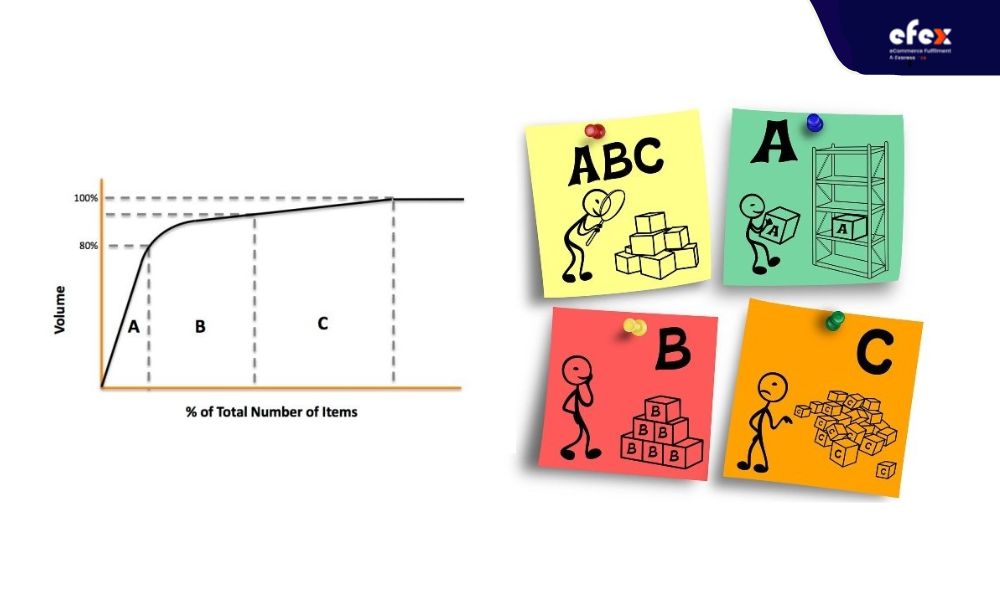

Utilizing the ABC Analysis approach, inventory is divided into three categories. The profitability of each SKU determines the category.

Let's have a look at this in more detail!

When you divide the inventory into categories like the ABC Analysis method, your company can sell a variety of products. What is the significance of this? Because different product lines allow for different refilling techniques for different categories. If you're a bag store selling $1,500 bags and $30 key ring accessories in the same store, you're not going to employ similar fulfillment tactics for both. The value of one product exceeds the value of the other. As a result, employing the ABC analysis technique gives you better control over the replenishment of each product, especially when combined with an inventory control system.

The just-in-time inventory strategy, or JIT, is for your company if you don't need to store a huge quantity of inventory on hand. Businesses that just have to stock orders as they are bought by buyers use this method. The quantity of filled orders is usually equal to the volume of inventory. The JIT approach can be seen in companies that sell seasonal items. They order just enough to meet orders as demand for their items grows. As the season draws to a close, they can empty the shelves without concern of losing money on unsold inventory. This method is not for you if your business relies on buyer trends. Unexpected spikes in demand, such as those seen in numerous industries during Covid-19, can result in costly stock-outs.

Dropshipping has quickly become one of the most widespread and approachable inventory management methods. However, because business owners don't handle the product, it's not precisely an easy inventory technique.

When a consumer places an order, you, the business owner, fulfill it from the manufacturer and send it to them immediately. You don't even look at the inventory. This method is typically used by first-time online sellers who don't have the financial resources to invest in a storage facility or warehouse. While dropshipping may appear to be a no-brainer, the disadvantage is that you have no control over the consumer experience. Because the manufacturer performs the majority of the work after a client buys the product, they have complete control over how the product is stored and distributed. If a consumer receives defective or inaccurate products, they will turn to you for assistance.

Sellers who sell things with expiry dates prefer the first-in, first-out method. FIFO standing for first in, first out, refers to the order in which products arrive in a warehouse and are delivered to customers.

It isn't simply for businesses that offer perishable items. If you want to get rid of a product quickly, you can use this method. However, keep in mind that the price trends of your items and resources should be analyzed. If prices fluctuate often, the gap between the cost of products received and the cost of items sold might result in overstated earnings. Retailers that sell perishable inventory utilize two more inventory methods: FEFO (first expired, first out), and LIFO (last in, first out).

Another common method for managing inventory employed by businesses is to keep the additional product on hand in case demand rises unexpectedly. Safety stock, unlike the JIT method, allows you to cover unanticipated delays and demand fluctuations while maintaining consistent output. Businesses use safety stock to prepare for things like inaccurate forecasting, fluctuations in consumer demand, and differing lead times for different raw materials. Since you have additional inventory on hand when you keep safety stock inventory, you can address the challenges.

Learning how demand changes for your product category over time are the first step in improving inventory management, particularly if you're opening a brand new online website. You can do this by looking at how search volume and interest have evolved over the last 12 months or even five years using Google Trends. And here is an illustration of when people are looking for snow boots at different times of the year: Interest begins to increase as early as September and peaks in most years around December to February next year.

By gaining a better grasp of patterns in this way, you can better predict when you should order more or less of the things you offer. If you already have an eCommerce website, you can use Google Analytics to discover which pages and items your visitors spend the most time on and how long they stay there. This information will show you not only which products pique your audience's interest, but also which items are hot and need more buffer stock.

Simply analyze previous sales to understand the period when demand and interest were at their peak. Plan for increasing demand by looking ahead to locate big selling opportunities throughout the year, such as holidays and festivals. Then, to avoid any items running out of stock during peak demand periods, order and store inventories properly. Refer back to the analysis you did with Google Trends and Google Analytics if you don't have any sales history.

If your online store is already up and running, you need to determine minimum sustainable stock levels for each commodity you sell. Remember that your objective is to establish the smallest amount of inventory you can have while still meeting demand and preventing fulfillment delays. You'll need a thorough understanding of demand and the time it takes to update out-of-stock inventory to arrive at your number. Place a fresh order with your manufacturer or reseller when volumes fall below the number you specify. Consider this exercise to be a beginning point. Don't be scared to change this quantity over time when demand from customers increases or decreases.

If you're operating an online business that will benefit from a specific shopping season such as the holidays and summer, do everything you can to prepare. During slow months, keep inventory low, but don't leave it too late to scale up your supply. To stop carrying too much dead stock close to the end of a peak season, promote special offers to move off the majority of inventory. Maintain minimal operating expenses for as long as possible, and use the downtime to ensure you have all the pieces in place—partners, tools, warehouse storage, personnel resources, tools, and so on—to ensure a smooth and profitable sales period.

You definitely really have to engage in inventory management software nowadays if you want to develop and scale an online store. Inventory management tools help you keep track of stock, and make sure you're never in overstocked or understocked situations. It also assists you to sync inventory tracking throughout all of the channels you offer items on, compiling real-time inventory data into one easy-to-use system, and providing you with valuable insights you can use to capitalize on opportunities, increase sales, and expand your e-commerce business.

Your company's most valuable asset is inventory. Creating a strong inventory management system can greatly simplify your job. Using a combination of the correct software and strategies, you'll be able to keep track of your inventory and make more money. In the end, it implies a more satisfied customer who will return your website. Use the e-commerce inventory management strategies outlined above to make better purchasing decisions, improve warehouse organization, and acquire a better understanding of how much you have in your warehouse and where it is.