More Helpful Content

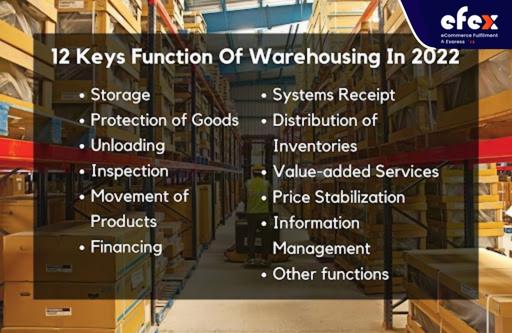

A warehouse is defined as a place specialized in efficiently storing products as well as supplies. Warehouses can be used by practically all types of businesses. Indeed, warehouses are required by a variety of companies, including transportation and customs, among others. In the most basic sense, a warehouse is a structure used to store goods.

In practice, though, it is considerably more. While this work may appear modest in comparison to other business process sections, it's important to remember that it's a dynamic activity that can yield a positive return on investment if done correctly. At the end of the day, a warehouse's role is critical. Let's look at the functions of warehousing to better grasp this statement.

They explain the functions of warehouses as stocking, managing, and regulating your work-in-progress inventory. So, what are the aims and functions of warehouses? The functions of warehouse are critical for your company's growth to have a robust warehousing method for your goods.

This is the step at which the items that have been collected and inspected are transported to their system-assigned places on warehouse racks. Block-stacking is no longer often used in warehouses. Loads are put on the warehouse floor and placed on top of each other to a safe height in block-stacking. Although it saves storage, this might be inconvenient for using. The IMS assigns places for commodities entering the warehouse based on warehouse management's put-away rules.

Bar codes are commonly used to identify goods for storage. Computers can scan bar codes. Data is converted into usable data using bar code scanners, including product and packaging information, location, and so on. Based on the concepts of FEFO (First Expiry – First Out), FIFO (First In – First Out), LIFO (Last In – First Out), and others, the IMS devises a storage pattern that allows the stored items to be conveniently retrieved for subsequent distribution.

Some warehouses employ light technology, in which a system-controlled light directs the operator to the specific location where the items should be placed. A put-away report lists the products that have been delivered into the warehouse, as well as their particular information and warehouse location.

👉 Read More: All Cost To Rent A Warehouse

The goods kept in a warehouse, as well as the warehouse infrastructure, may have a value of millions of dollars and require protection from damage, theft, pilferage, fire, and other threats. Warehouses have a responsibility to protect the items that have been committed to them by their customers.

For the security of the property and products, CCTV cameras, alarms, motion sensors, and adequate patrols in and around the warehouse perimeter are required. A security manager may be assigned to a big warehouse to oversee such concerns and to communicate with the fire station, local police force, and other local authorities.

Road transport is generally used to transport products to a warehouse. Goods Inward are the name given to such items. Whether it arrives by cargo ship, goods train, or aircraft, it must be transported to a warehouse using a truck or other proper transportation, regardless of how close it is to the quayside, railway station, or runway.

The warehouse operations manager must prepare ahead of time and assure resources and procedures for handling such products are in place. This is referred to as a Goods Inward Plan (GIP).

The warehouse operations personnel must guarantee that the packing list accurately reflects what is collected at the facility. Both the packing list and the bill must be identical.

A goods receipt inspection involves, but is not restricted to, ensuring that the amounts are accurate, that the prices listed are correct, and that the products are not damaged or of poor quality when acquired. Any inconsistencies or other concerns should be noted and brought to the notice of the operations supervisor, who will subsequently bring it to the stock control staff's attention. Such difficulties are reported to the shipper, the carrier, or the insurance agent by the stock administration team.

After the products have been unloaded and inspected, the warehouse operations personnel creates an Inventory Receipt Report (IRR) for each consignment. The IRR will include information on the products delivered, such as specifics about products received in low supply, expired or broken goods, excess receipts, as well as other related information.

It consists of the following components:

To ensure uninterrupted or timely delivery of products, the movement of goods and services throughout a warehouse must be as smooth as possible.

A warehouse's various roles also include financing. Warehouse finance is a sort of inventory financing that entails a financial institution providing a loan to a factory, business, or processor. Products or inventories are put in a warehouse and then utilized as collateral for the loan in this situation.

When products are delivered to a warehouse, the depositor is given a receipt that serves as proof of the products' arrival. A 'Warehouse-warrant' keeper is a document issued by the warehouse in favor of the products' owner. This title document can be handed on with just an endorsement and receipt. As a result, although the items are in the warehouse custody, the keeper's owner can get loans through banks or other financial organizations by using this warrant as collateral.

Besides, warehouses can also provide cash advances to depositors for a limited time while holding their products as collateral under certain circumstances. Borrowers can profit from warehouse finance in a variety of ways. The flexibility of borrowers to utilize their raw materials, products, and other assets as security for the loan is a key advantage of warehouse finance.

Unlike unsecured debt or short-term capital, warehouse finance frequently allows borrowers to get financing on better terms. Furthermore, warehouse financing conditions are quite flexible and often beneficial to the debtor, small firms, and factories that employ this sort of credit. Because it is a secured loan, it is frequently less expensive than other kinds of borrowing.

The received amounts are approved in the IMS (warehouse Inventory Management System) when the products have been stored away. The warehouse's Stock Administrators are normally in charge of this. They'll account for the precise amounts obtained at the accepted pricing, accounting for damaged goods, short receipts, and so on. A GRN, standing for Goods Receipt Note, is generally the result of this process. When a GRN is issued, the individual products are often available in software systems for re-distribution or selling.

Stocks are distributed across the warehouse in response to items ordered from internal or external customers. Goods Outward are stocks that have been issued. The majority of IMS is set up to instantly transfer orders into processing systems. Following the upload of orders, the system identifies out-of-stock products and provides a Pick List (PL) for the rest of the items, indicating the places from where the operator should pick them up.

Besides, light-based technology, similar to that used for put-away, might be utilized to lead the operator to the correct spot where the products are to be picked. An invoice or Goods Issue Report (GIR) is issued based on the final Pick List. The supplies are then transported to the loading area as shown in a loading plan.

The operations supervisor creates a Daily Loading Plan (DLP) that takes into consideration the full amount of orders to be shipped for the day as well as the urgency of every order. For the transportation of these products, the necessary vehicles or truck trailers must be prepared, as well as personnel to conduct the loading activities.

Customers are frequently given value-added services by warehouses in order to keep them as well as attract potential customers.

Other services include stamping, labeling, gift packaging, order fulfillment, barcode and invoice printing, insurance, quality control, and product disposal are some the other value-added services supplied by a warehouse. The integration of such useful services with the warehouse relieves the entity using the warehouse of a significant amount of strain and allows it to focus on its core business. As a result, expenses are cheaper and standards are greater.

Warehouses are vital in the price stabilization process. They assist in the management of price movements through:

Once there is a surplus of market demands, the increased entry of goods may lower their price even further, causing losses for company owners. As a result, the warehouses in this situation keep the stock till the market demand for such items increases again. This is how warehouses assure a steady supply of products in the market by balancing supply with demand, resulting in price stabilization.

Warehouses maintain track of data regarding items and materials that are collected, stored, and delivered out of the facility. Aside from that, any extra data about the warehouse is kept track of. It enables warehouse managers as well as other relevant staff to obtain precise data on stock availability, stock handling, and stock replenishment needs. The information kept by the warehouse's data system must be accurate, fast, and error-free. It may even be provided to upper management in order for them to make better and more informed judgments.

Aside from the duties listed above, warehouses can additionally implement the following tasks:

When products are transferred for storage, the warehouse keeper assumes responsibility for them. As a result, the warehouse keeper bears the risk of product loss or damage. Because it is now the warehouse's responsibility to return the products in perfect condition, it is now liable for any mishaps. As a result, it takes all necessary safeguards to avoid a situation like this. In addition, the kept assets may be insured for reimbursement in the event of a loss.

Some warehouses may also generate additional income for their owners by renting them out to individuals or businesses who need storage or other services.

To facilitate the transfer of products, warehouses are generally built-in handy locations, such as near an airport, train, road, or river.

Warehouse management often obtains insurance coverage for the stored products and the warehouse infrastructure among other types of equipment. Warehouse insurance comes in a variety of forms. These policies contain both partial and total coverage for events such as floods, fires, and other kinds of damages. However, it must be proven that the loss occurred despite the warehouse taking all reasonable precautions to prevent it.

👉 Read More: The Role Of Warehouse Management In Supply Chain Management

👉 Read More: Top 12 Warehouse Management System Features

Now that you have a good grasp of warehousing, it's much easier to move forward with your business. By evaluating these functions of warehousing, it is possible to infer that a warehouse is far more vital to a company's success than most people know. To ensure that all warehouse processes run well, proper supervision of these functions is essential.