More Helpful Content

The Logistics network is considered to be the backbone for the process of converting materials into final products and delivering them to customers. Most people recognize that the logistics networks are vital to their operations' performance, but they don't have clear visibility of them. In order to acquire a full-field picture of your whole logistics network to achieve success, you'll need excellent inbound and outbound logistics. These procedures have an impact on productivity, earnings, and customer service, which are all important aspects of any organization.

However, there are various obstacles to overcome when it comes to logistics, and the expenses of not optimizing these operations can be extremely large. In this case, implementing the proper controls can help your company's performance. Let's look at what inbound and outbound logistics are and their purposes and differences.

This process emphasizes the demand aspect of the supply-demand relationship. Outbound logistics operations are involved with the transfer of finished products from a distributor or fulfillment center to their final destination.

👉 Read More: 3PL Vs 4PL: What Is The Difference Between Them?

👉 Read More: 3PL In Supply Chain: Definition and Benefits

To fulfill demand, a business maintains a specific amount of units on hand. Outbound logistics operations secure and arrange these products in the proper conditions. In warehouse management, outbound and inbound logistics sometimes overlap. Outbound logistics, on the other hand, is concerned with the transportation of finished goods. Inbound logistics is related to product purchases for businesses that offer final goods received from suppliers, whereas outbound logistics handles orders given directly to customers and delivers the goods to retail outlets.

Inventory management, a procedure that identifies the optimal location to store products in the warehouse for efficient order fulfillment including order picking and packaging, is sometimes assisted by software. Stock and order accuracy, and also ensuring the quality of the product by avoiding damage, loss, expiration, or spoilage, are all purposes of inventory management.

Regardless of the types of products, several modes and techniques of shipping are used. Huge commodities including heavy machinery, for example, may be shipped in smaller lot numbers by truck. Besides, perishable products like fresh flowers may need to be carried in cooled containers by plane.

The importance of on-time delivery cannot be overstated. In addition, the orders from customers must include the right products and quantities. The package must also not be lost or damaged during transportation. This is a stage that is handled by outbound logistics.

The distribution channels through which your items reach the client have an impact on how you handle your outbound logistics. Direct distribution channels are when you sell the product directly to buyers, while indirect distribution channels are when you sell goods through a middleman such as a retailer or a wholesaler. Here are some distribution techniques available:

You should consider logistical difficulty, price, time, quality, customer satisfaction, as well as control when selecting distribution networks.

The last shipment leg and fulfillment are covered in the final phase of an order's route. The last mile seems to be the most expensive and inefficient aspect of the shipment. The term dates back to the early times of telephone service, as connecting houses to the mainline was both time-consuming and costly. Home food shipping from a local supermarket and delivering packages by a carrier are examples of last-mile logistics. Shippers can deal with a large number of orders simultaneously before the last mile. However, since every package travels to a specific address, each one requires special processing in the last mile. Last-mile deliveries account for around 41% of total supply chain expenses, with deliveries dispersed over a suburb area or crammed into a congested city center with limited parking.

Improving delivery requires not only lowering costs but also satisfying rising consumer demands for quickness and transparency. These two aspects frequently go hand in hand. The route optimization system organizes orders for distribution more effectively, arranges products by route, plans the optimum route traffic volume, fuel usage, and other factors, and assigns ways to drivers.

Outbound logistics difficulties can have a negative impact on profits as well as customer satisfaction. Stock and shipping prices can quickly escalate, and consumers will leave if orders are inaccurate or delivered late. Here are some major logistics issues for outbound logistics:

Manufacture, warehousing, and delivery must all be monitored by outbound logistics staff, and arranging the most efficient transfer of goods is no easy undertaking. If manufacturing expands, the logistics department will have to free up additional storage space. Besides, delivery will need to increase to cope with the increasing customer demand. By linking manufacturing to storage space and demands, technology and automation will help complete the data loop.

To meet these goals on a consistent basis, you'll need an integrated information system that leverages data to evaluate productivity, identify weak points, and monitor and drive continual improvement.

It takes careful planning to have adequate stock to fulfill variable customer demand without incurring extra holding expenses. It's also critical to monitor stock control metrics including sell-through percentage and inventory turnover, as well as data like safety stock and demand fluctuations.

Transportation is a significant cost in outbound logistics. Businesses can reduce expenses by evaluating the previous spending and identifying inefficiencies. Experiment with different methods such as carrier volume discounts, dynamic pricing, bidding for your product lines, and checking at freight markets.

Consumer expectations keep rising, and free, quick delivery is now the rule. In some areas and businesses, same-day or even 2-hour shipment is the norm. Customers want to see their orders' progress in real-time and follow them on a map. To keep up with this trend, logistics staff must grasp the significance of shipping as a key differentiator as well as the long-term effects of a bad customer shipping experience.

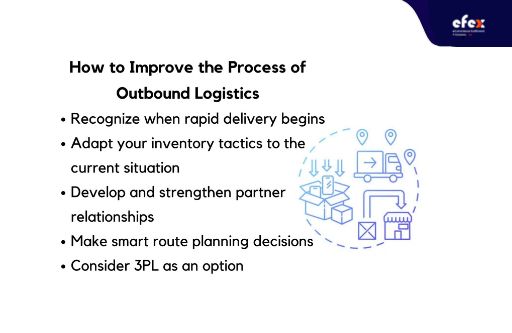

Invest time and effort in partnerships and discussions to boost the outbound logistics process. Employ technology to design distribution networks, routes, and schedules, as well as to keep prices low.

You may have to establish product staging at fulfillment centers, filter deliveries according to distribution hub guidelines, and adapt packages to satisfy carrier needs for the speedy shipping. In several industries, there is a lumper service, which utilizes third-party employees to lift and move trailers. the purpose is to shorten the turnaround time so that the truck driver may rest and go sooner.

Bulk quantities shipped to buyers at evenly spaced periods are no longer the norm, thanks to JIT (just in time) inventories as well as other quick replenishment techniques. Since most JIT customers don't have the space to retain a lot of surplus inventory, you'll need to adjust your outbound logistics to accommodate these inventory patterns.

Collaborate closely with essential outbound logistics partners, such as your clients and freight suppliers. Depending on your business, you can sell to large retailers with deep experience in their extensive supply networks. They may provide information on how the product is performing if you have the perfect partnership, allowing you to fine-tune your manufacturing, order fulfillment, and delivery. You may know if spreading your business across a few carriers provides you greater control over cost and service agreements by close collaboration with freight forwarders.

An automated journey strategy will minimize waiting and transport time for shipments. These time savings can help save money on fuel and improve the customer experience.

Outsourcing international logistics to a 3PL might be a reasonable option for many companies due to the expense and difficulty of outbound logistics. Because of their scale, 3PLs may get bulk discounts with negotiating leverage, which can save you money. 3PLs also offer knowledge, specialization, and the ability to swiftly scale up or down your operation based on business needs.

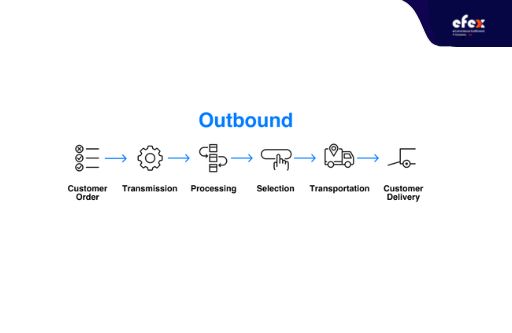

Outbound Logistics Process Flow has 6 steps:

Vintage May is a nationwide boutique business with 37 locations. On the Efex website, the firm orders a range of women's dresses in varying amounts in women's sizes 18 to 30. Vintage May decides how much each product and size to buy based on internal data regarding buyer preferences, previous sales, and trend projections. Efex must pay particular attention to the specifics of the order. Customer complaints and missed revenue for items that were not shipped in time for holiday shopping might occur from sending the incorrect product or quantity.

Vintage May's order is checked by Efex's order processing staff to ensure Efex has the correct amount, sizes, clothing styles, and colors available. Vintage May receives an order confirmation from them. Because of Efex's inventory management system, these products are no longer accessible for purchase by anybody else. To the warehouse, the system transmits an order manifest and picks tickets.

Employees transport goods from off-site storage to the distribution warehouse, where it is replaced as needed. Efex's strategists notice that a certain dress is selling better than predicted and request that more be made.

When picking apparel for various orders, warehouse workers employ a zone method. To identify the orders, they apply barcodes.

At the packing station, all of Vintage May's apparel pieces are gathered. To ensure that the order is right, a staff member scans the barcodes on the hangers. They stack boxes on pallets, shrink cover the pallets, and apply destination and manifest labels on the pallets. Vintage May's order was divided into two lots, one for its East Coast distribution location and the other for its West Coast distribution center. Because they aren't rush shipments, Vintage May's order will be shipped by ground. Pallets are loaded into departing trucks by workers.

The order has been completed. Vintage May's buying department receives tracking information from Efex's system, which registers the shipment. Efex 's network also notifies the chain's distribution centers of new arrivals.

Outbound logistics assists businesses in satisfying their consumers. Nothing is missing, damaged, or faulty, according to the procedure. The following are some of the unique advantages of well-run outbound logistics:

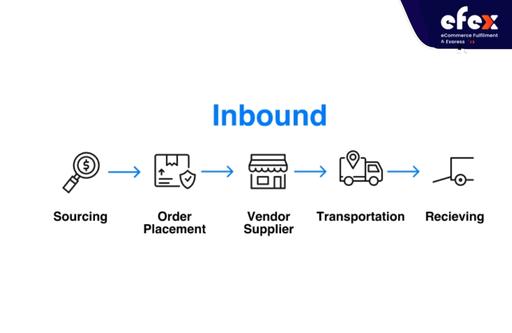

Based on company structure, inbound logistics procedures involve moving raw materials, final products, and supplies from a factory or other distribution route to fulfillment facilities, warehouses, or retail outlets.

Identifying and analyzing prospective suppliers, getting price quotations, dealing with, and managing suppliers.

Purchasing the supplies and products needed in the correct quantity and at the appropriate time.

Choosing between a truck, a plane, a railway, or another mode of transportation to transport products. This operation also includes deciding on incoming supply delivery pace, engaging with third-party shippers, and negotiating pricing and route with vendors.

Taking care of new items when they arrive, unloading trucks, and double-checking that they match the order.

This activity includes transporting received materials within the facility over short trips and storing them for future use.

This refers to the process of transferring items from the delivery point to storage. Everything is put away in its proper place by the staff.

Preparing supplies for manufacture or order fulfillment by storing and warehousing them. This department ensures that things are stored in the most logical areas for fulfillment and that the proper storage conditions are followed.

Inventory management includes determining the quantity and type of raw materials or products to keep, as well as their location.

Keeping track of the status and delivery schedule for items as they arrive at your plant.

This is the process of getting supplies to where they need to go inside a company.

Monitoring details about new orders, including their location and papers such as receipts.

Returning items to buyers for reasons like refunds, errors, delivery issues, maintenance, or refurbishing is referred to as reverse logistics. This is also utilized by recycling and salvaging companies that operate with old materials. A company's approach to inbound logistics differs depending on the entering products, the sector, and the buyer-seller relationship. Inbound logistics might be handled in-house or outsourced.

Here are several inbound logistical challenges you may face:

Some businesses spend an excessive amount of money on shipping. You may save money by negotiating discounted rates with several carriers and combining inbound shipments into full truckloads. You may also specify pricing and service vendor inbound compliance standards (VICS). Metrics may help recognize any inefficiencies in terms of time or money.

One common problem is not realizing where cargo is, when it will come, or the price. Some organizations hold overstock, make orders too early, and have delays in manufacturing and client delivery as a result of their lack of understanding. Real-time systems enable a business to identify and track shipments as well as connect with suppliers in order to ensure that appropriate data is obtained when inputting products.

Businesses might find up handling too many deliveries at once if they don't prepare beforehand. As a result, their facilities get packed with trucks, making it difficult for drivers to choose the dock. Lulls and peaks in delivery make it difficult to employ receiving staff properly. Mistakes and material backups result from a faulty receiving procedure. Arrival timing, delivery routing to certain ports, and keeping a regular tempo during the day are some of the solutions. Logistics can be aided by warehouse management software (WMS) or cross-docking. Workers unload commodities and immediately transport them to the next dock to load them onto an outbound vehicle, never storing them.

Returns management is an issue for some businesses, resulting in lost sales when inventory is not swiftly replenished. Additional issues include poor inventory counts and low client satisfaction. To fight this issue, set clear, fast returns processes and explain the significance of returns management to employees.

A business need trusted suppliers that can provide both reasonable price and high quality. However, finding and keeping dependable suppliers may be tough.

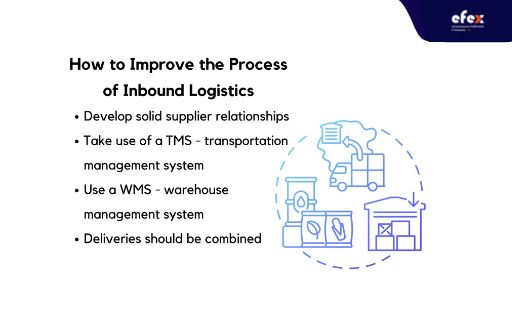

The following are among the most commonly recommended steps for enhancing incoming logistics:

Better terms, shorter lead times, cost reductions, and a feeling of security throughout market moves can all be gained through strong supplier agreements. Furthermore, emphasizing this partnership allows your supplier to have a deeper understanding of your company.

Freight operations are automated, controlled, and improved with this software. A TMS evaluates shipping rates and service levels across carriers, organizes the item, and follows it until it arrives. These insights aid a company's cost-cutting, efficiency-boosting, and supply-chain visibility efforts.

Receipt, putaway, inventory control, picking, and other warehouse processes are all streamlined by WMS software.

LTL shipments (less-than-truckload) are more expensive to send and take longer to receive. Consolidating shipments might be difficult at times due to differences in handling requirements. If a company is having trouble filling full truckloads, it might use a third-party logistics provider (3PL) to merge its half loads with other clients.

The incoming and outward logistics of a firm are determined by what it sells and its business strategy. An instance may be used to demonstrate how these procedures function. Here's how Efex, a clothing manufacturer, handles logistics.

Efex determines how much fabric, buttons, thread, zippers, as well as other materials it will require to produce its forthcoming autumn fashion collection in order to reach its projected sales volume. The procurement department collaborates with the designers to identify vendors for each component that fulfills Efex's pricing, color, style, volume, and delivery schedule requirements. Each vendor's contract is negotiated by the buying manager.

A procurement secretary creates purchase orders, transmits them to vendors, logs them, and compares them to invoices.

Vendors give electronic order confirmations, as well as delivery and tracking information.

The goods arrive on trucks at Efex's facility.

Efex's receiving personnel unloads the arriving items, counting and identifying the products using barcodes or RFID tags. The amount and quality are compared to the purchase order. The supplies are transported to the warehouse, then they will be processed into garments.

The receiving department also handles store returns of unwanted clothing. Their contracts require merchants to return unsold goods in exchange for a partial reimbursement toward the order of new season products. The staff that handles orders from bargain retailers and liquidators keeps last-season clothes in a staging area.

Businesses may profit from inbound logistics in a variety of ways, including more trustworthy supply sources and cheaper raw material prices. More advantages of effective inbound logistics include:

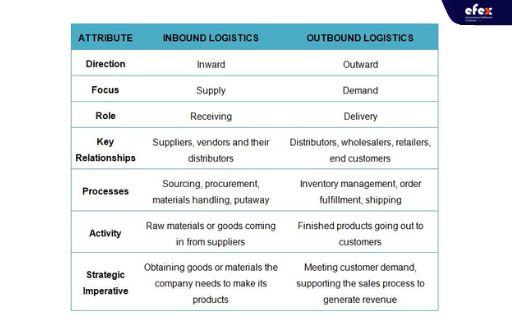

The key distinction between inbound vs. outbound logistics is who receives the items and materials. Inbound logistics entails receiving items from the manufacturing facility or product developer in the setting of a warehouse that fulfills directly-to-buyer orders, while the outbound logistics process focuses on delivering things to end customers. Here is the table below comparing inbound and outbound logistics processes.

👉 Read More: 3PL Cost: All Fees And Why You Need To Pay (Update 2023)

An effective incoming and outbound logistics network is needed for supply chain efficiency. Final items must go through various stages of the supply chain before reaching your final customers. If you'd like to learn more about how a professional fulfillment and logistics service provider can help you manage inbound and outbound logistics more effectively, don't hesitate to contact Efex - the most reliable fulfillment and express in Vietnam, they will resolve all of your problems you have.