More Helpful Content

When it comes to small business inventory management, ensuring an efficient, precise, and dependable system of inventory management is very crucial. This will aid businesses in cost management and ensuring a sufficient supply of goods to satisfy consumer demand. Businesses can save money and boost cash flow by using effective inventory management in small businesses. In this article, we will go through inventory management in small businesses, the reasons why it is hard, and barcode inventory management for small businesses. Let's scroll down to read right now!

Most large businesses have come up with the concept of implementing advanced inventory control over time. Given the volume of goods they transport and their profitability, investing in instruments that would pay off in the long run made sense, even if the capital cost was marginally higher. Nevertheless, one of the most common misconceptions nowadays is that inventory management software is only suitable for large businesses. There is now enough evidence to indicate that smaller businesses may benefit a lot more by optimizing their processes with cutting-edge technology.

👉 Read More: 15 Inventory Software for Small Businesses In 2023 (Free + Paid)

Smaller businesses are affected the hardest by the costs of carrying extra inventory, which is one of the main reasons why inventory management for small businesses is so important. They can not afford to lose out on big orders because their warehouses aren't fully stocked. Moreover, many small firms are engaged in the sale of seasonal products. You don't want to find yourself responding too late to a shift in demand if you're running a tight inventory for such a business. You can analyze your inventory data and generate reports that help you predict future trends with inventory management software. As a small company owner, you should look for a small business inventory system that is both affordable and tailored to your specific demands.

Inventory management is a science and an art, as well. Due to a variety of factors, smaller companies frequently struggle to keep up with inventory management. The following are some of the most frequent inventory management errors made by small business owners.

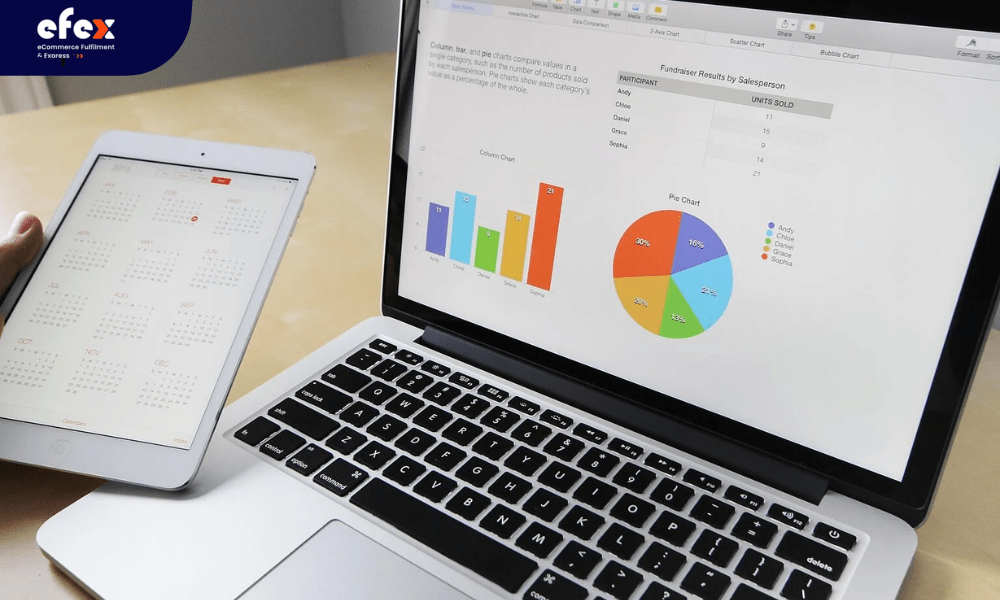

Small business inventory spreadsheets might be a nightmare to work with. It becomes extremely harder to decrypt them after a certain point. Businesses that are scaling up frequently become enmeshed in several spreadsheets, limiting their decision-making abilities and limiting their efficiency. While inventory sheet for small business includes certain automation features, it is impossible to completely automate the inventory process. As a result, you manually amend the sheets. Compare this to an effective inventory management tool that helps you automate several time-consuming procedures, reclaiming your time and enabling you to focus on other important responsibilities. Moreover, it also changes the way data is represented. You won't have to spend any more time staring at spreadsheets and struggling to figure out what they mean. The software evaluates the information and generates a number of more precise and understandable results.

If your stock levels aren't based on sales, you'll either have overstock or an understock situation. The number of goods in your inventory should always be determined by your anticipated sales. Keeping a consistent inventory for small businesses will not always be possible. Make the process as dynamic as possible. Before deciding on your inventory levels, think about shelf life, demand, return orders, and profitability. A good inventory management solution can assist you to manage all of these tasks without spending too much money.

In the long run, the state of your inventory will affect your sales. Businesses that fail to monitor and maintain their inventory management systems on a regular basis frequently encounter problems without warnings. Your stock must be properly accounted for at all times. If left ignored, any discrepancy between your physical stock and the figures in your monitoring system can experience serious consequences. Scheduling inventory audits on a regular basis seems redundant at times, however, carrying them out strictly is always a smart practice for your warehouse.

Inventory loss involves the unwanted reduction of goods from an inventory owing to causes such as expiration, adverse weather, shipping issues, and so on. Shrinkage is a problem that must be addressed on a regular basis by keeping track of it. Businesses that do not account for shrinkage are more possible to oversell their stock. In other terms, they'll sell things that they won't be able to deliver because shrinkage has rendered most of those goods outmoded or unfit for sale. This leads to order cancellations, then unhappy consumers. These issues may be eliminated by keeping an eye on shrinkage.

Another vital part of a healthful inventory is stock clearance. Your expenses should reflect the market's need for the goods you're providing. If you raise them too high, you risk not obtaining enough sales. You risk losing a few well profitabilities if you reduce them too low. The idea is to keep track of the market at all times and the other of the costs of your inventory. You can manage your stock like an expert if you can walk this tightrope.

Simply stated, inventory management relates to the administration of all complete and incomplete goods, as well as their storage and use. This is aided by cyber-physical techniques, as well as it is critical to the success of a business. When a small business has eliminated production bottlenecks and achieved favorable sales figures, inventory management becomes a major concern. Small businesses use spreadsheets or the antiquated traditional way to tackle it. These are only temporary solutions because they allow you to manually enter input and output stock as well as a limited amount of information about the items. The following are some of the most common indicators that inventory management in small businesses is in need of improvement:

If you're experiencing any of the above issues, it's time to invest in strong inventory management software for your small business.

Managing an inventory small business is simple since you only need to keep track of a few pieces of data about the goods you have on hand. This covers the quality assurance tests performed when they are received, the vendor, quantity, batch number, present position in your warehouse, the length of time they will remain there before being replaced, and storage instructions. You'll need inventory management software as well as tools like barcode scanners and printers.

Whether it's a small firm or a big company, inventory management is critical. Inventory must be properly managed, monitored, and secured. A barcode can help you keep track of all of your small business inventory storage in the most efficient way possible. It will also assist you in saving a significant amount of time and money in all aspects of your organization.

Are you curious about a barcode and how it is used? The explanation is simple: a barcode is an information representation way that is both visually as well as machine-readable. The spacing and width of parallel lines are changed to identify barcodes. In 1949, barcodes were created.

👉 Read More: Top 10 Barcode Inventory Management Software in 2023

Barcodes aid in the reduction of all types of error risks. Manual information entering into a computer, on the other hand, is not a strong concept for keeping accurate data. When inputting other critical information or tracking an item, inaccuracy happens once the wrong keys are touched by accident. Barcode systems remove the dangers of manual entry and help to reduce unwanted errors. With a barcode scanner, there is no necessity for manual entry since everything is fully automated only by checking the barcode.

Another importance of barcodes in inventory management techniques is lowering operating costs in warehouse management. Because of their widespread use, they have decreased the overall cost of the equipment. It's a one-time spend that includes purchasing machines and equipment. Following that, just the costs of maintenance, repair, and management are required. It will save you money in the long term by providing correct data to re-evaluate your overall expenses.

When you manually enter all of the data, it takes a long time. Adopting technologies and software in today's technology-based society minimizes redundancy and saves a lot of time. You can save a huge amount of time with barcoding because it eliminates the need for manual data entry. All you have to do is scan the barcode tag and everything is taken care of.

Barcodes are more commonly used in managing inventory in small businesses preferably than in point-of-sale trades. Because all goods have a UPC, retail store managers can easily follow the necessary stock in the warehouse and on store shelves. As a result, knowing the right spot and product quality in the supply chain is critical. You can create a safe zone for your firm by looking after your investments, and your workers can believe you without hesitation. [caption id="attachment_4649" align="aligncenter" width="1000"] Inventory tracking made simple[/caption]

Inventory tracking made simple[/caption]

When pricing varies, it causes a lot of problems, such as how to penalize it, apply it, update goods according to the new pricing, and so on. Having price tags attached to goods also becomes a costly, time-consuming, and laborious procedure. You may have the price shown on the goods rack on the barcode label itself by using barcodes. It will take a shorter duration and effort to update the price of each package when needed. When the price of a barcode is changed, it has an impact on the entire barcode database.

Besides inventory tracking, barcodes assist in the efficient management of the entire stock. Other actions have arranging machinery maintenance, adding information, keeping track of the shelf life of supplies and devices, and so on. A barcode technique is designed to handle all of these tasks without assistance, hence increasing business revenues.

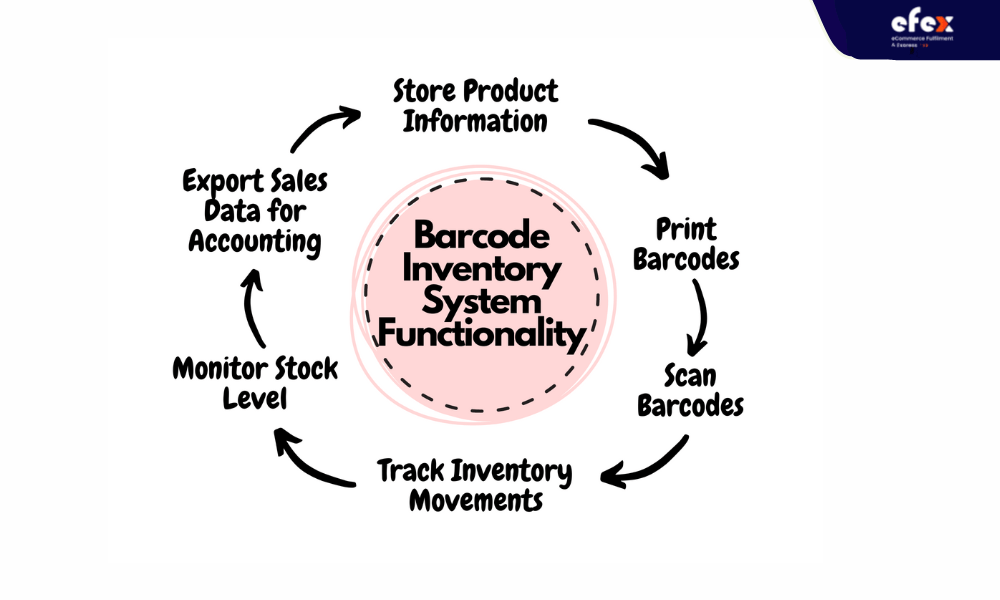

You can set up your small business barcode inventory system with the aid of a computer equipped with inventory management software and connected with a barcode scanner. You must also follow the instructions outlined below

Barcodes are the first item you'll need. You can't generate barcodes until you enter product information into your inventory management system. As a result, you must import a spreadsheet containing product data into your inventory management system. You can manually enter product information into your inventory management system if you don't have a database of your product information. The inventory management system then creates barcodes for each product depending on its specific characteristics, such as color, size, manufacture, model, and brand. You can then print the created barcode labels with the barcode printer.

When you have barcode labels available, you must manually paste them on each product in your warehouse to ensure that they are uniquely identified. This is the most time-consuming step, and it necessitates a significant amount of human labor. However, once you've completed it, you'll have a clear picture of the number of each product item accessible in your various warehouses. All issues connected to missing items, overselling, and missed sales are resolved when the system's information matches the actual supply.

Scanning barcode is one of the important inventory management techniques, helping control your inventory more effectively and increase visibility. The final and most important step is to scan the barcodes of each item in your shop so that the system has a proper record of the stock and inventory available to buy. When goods enter your warehouse, the barcode scanner helps you add them to the system and subtract them from the inventory when they depart. If you don't scan the product's barcode while buying or selling it, your system may well not reflect an accurate inventory level, resulting in a slew of accounting problems and managerial concerns.

Selections can be tricky when choosing a barcoding inventory system because you need the optimal set of scanners, printers, and software. Because inventory management software is such an important component, choosing the best one is crucial. The first wise step would be to go over the list of the best inventory management systems. Aside from that, you should think about the following things when selecting a barcoding inventory system that will assist your company the most.

Before you choose a barcoding inventory system, make sure it can handle your needs.

Considering the aforementioned factors will aid you in selecting a barcode inventory system that is appropriate for your company's needs.

The barcode inventory system you choose should be able to interface with your existing systems, such as small business inventory and accounting software, ERP, CRM, and so on. Furthermore, your barcoding system should be compatible with Microsoft Office and other important software used to input product data into the system.

The barcoding system you use should be flexible enough to meet your company's changing demands. If you don't plan to expand your product range or the number of warehouses you have, investing in a barcoding system can be a financial strain. Changing a barcoding system on a regular basis might be inconvenient and slow down productivity. As a result, it's a good idea to start with a scalable barcoding system.

You may shortlist the barcoding system that is straightforward, well-featured, and user-friendly based on these user reviews. You may read customer evaluations for the barcoding systems inventory management on a variety of platforms.

Several barcoding inventory system suppliers provide a free trial or demo. You can take advantage of this service to see if the system in question follows your business logic or not. It's a good idea to try a demo or a free trial before spending a lot of money on a barcoding system.

The price of the barcoding system is the last but most essential consideration for small enterprises. This is the biggest decision you'll make because a cheap barcoding system that doesn't work properly can end up costing you a lot of money in the long term. As a result, you must select a barcoding inventory system that offers the features your company needs while also fitting within your budget. If your budget doesn't allow you to invest in a new software system right now, you can look over the details of the top free and open-source inventory management solutions. However, you must guarantee that you have sufficient technical staff and infrastructure to deploy open source and free inventory management software and make it realistic for your business needs.

An effective small business inventory management system ensures that you always have an accurate view of your inventory, allowing you to reduce waste and give your consumers the product and experience they expect. This system can help you set up and simplify your operations, whether you're trying to master the basics of how to arrange inventory for small businesses or revive an existing system that has gotten unorganized. Additionally, implementing the ideal barcoding inventory management system will also help you cut costs and increase revenues in your small business.