More Helpful Content

Inventory management is essential to a successful business and is reliant on the ability to foresee demand trends. Understanding the average inventory formula is also critical. So, what should you do if you have an excess of safety stock in your warehouse? You would not want to end up with dead stock on your hands, therefore inventory reductions may be necessary. Let's scroll down to learn more about inventory reductions, as well as some examples and tactics to implement.

Inventory reduction is the process of reducing inventory levels to the degree where they are sufficient to meet consumer demand. Inventory reduction is required to get rid of extra products, create extra warehouse space, save money, and boost profits. Besides, inventory reduction is also one of the most cost-effective inventory management solutions.

Excess inventory is an unfortunate reality for many firms. A lack of warehouse management, faulty demand projections, inadequate inventory control, and other factors can all contribute to it. Keeping track of inventory levels and establishing the best reorder point is essential for avoiding this problem.

Inventory reductions have a lot of advantages. These are some of them:

Excessive stock raises the cost of additional storage space. When you keep more inventory than is necessary, you are overpaying for the storage space and resources. You'll also have to pay for labor and transportation to relocate the stock. That's a lot of money spent on rental, storage, and labor for wasted inventory and lost profit. You'll have more space for inventory that's more likely to sell quickly if you can cut inventory. Reduced inventory also means less money is spent on staff to deal with excess stock. You can concentrate your energies elsewhere, in a properly sized warehouse.

It's irresponsible to order large volumes of goods in this age of perpetual technological innovation. Since product life cycles are becoming shorter and shorter each year, you must be flexible in the quantity of stock you order. You'll end up with unused inventory in your warehouse if you order too much of a product that will become outdated in six months. The key to success is having less inventory per product lifecycle.

Furthermore, people's shopping habits are constantly changing. You'll need enough free cash flow to handle a change in infrastructure as, for example, brick-and-mortar businesses go obsolete in favor of exclusively online sales. That means having sufficient cash to do tasks like develop a website and buy internet advertising without being completely reliant on inventory. Your business can be ready for industry changes at a moment's notice with decreased inventory ordered on an as-needed basis.

Inventory that isn't used is a waste. Not only do you lose money when you order too much stock and it stays in your warehouse, but you're also obliged to find ways to get rid of it. Customers will get accustomed to that price decrease and expect it in the future if you mark down the things in a panic. It can be difficult to overcome this.

If you're dealing with perishable products, they'll go to waste if you don't use them right away. Not to mention the environmental impact of discarding massive amounts of unsold inventory. Reduce inventory costs to cut down on waste and overall expenses. Spend the money you've saved on things to replace the garbage you've accumulated.

Besides, there are concerns about inventory reduction going too far. Among them are the following:

Outside conditions may also determine inventory levels; for example, an electric utility must be able to produce power continually, but if their fuel supplier's employees are about to go on strike, it would be a good idea for them to stockpile fuel.

Let's look at a few examples of how inventory reduction can be accomplished. Let's suppose you're a food distributor with a significant perishable food backlog. Your demand projection was off, and customers aren't buying in the amounts you anticipated. You decide to conduct a deal on an online marketplace to try to sell those things before they expire. To entice customers and improve eCommerce sales, all you have to do is calculate a reasonable discount and send out some eCommerce email marketing campaigns.

Next example, let's imagine your company has a problem with too much safety stock for a variety of products on a regular basis. Because the problem appears to be persistent, you can't pin the blame on a single instance. You make the decision to move your entire business to a just-in-time inventory (JIT) model. This model allows you to only accept orders as they are needed to fulfill customer orders.

This not only relieves warehouse congestion but also aids in the discovery of the sources of inventory variability. Seasonal demand patterns, incorrect order processing, or something else could be to blame. You may use the information obtained here to create inventory KPIs and make smarter judgments about how to streamline your inventory management process.

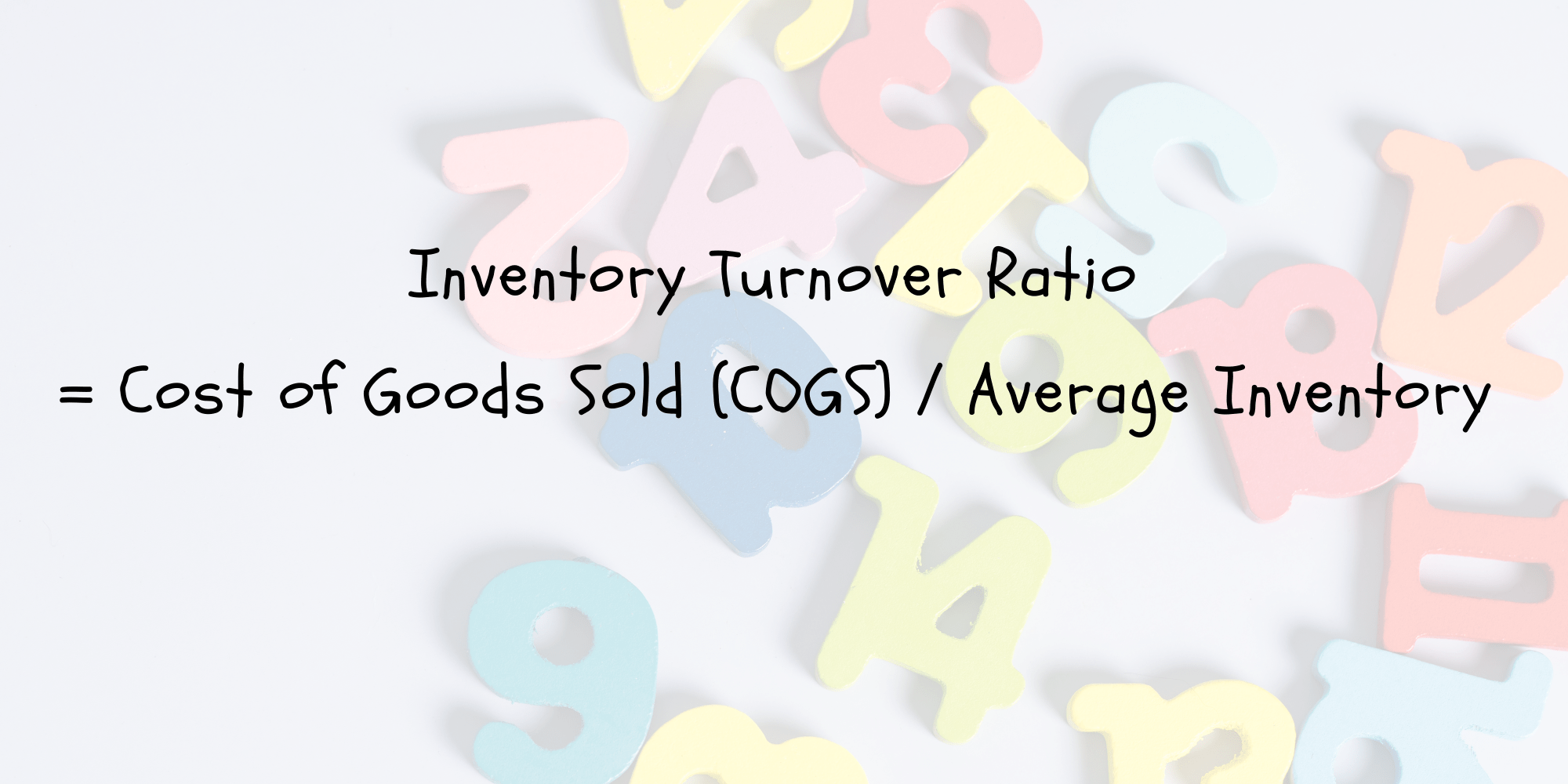

While there isn't a single simple inventory reduction formula, there are a few calculations that can allow you to figure out how much inventory to keep. To begin, determine your inventory turnover ratio, the total number of times you've sold out of inventory in a certain time frame. It's a useful metric for determining which goods have the highest demand and where you should devote your time and money. The formula for calculating inventory turnover is as follows:

Inventory Turnover Ratio = Cost of Goods Sold (COGS) / Average Inventory

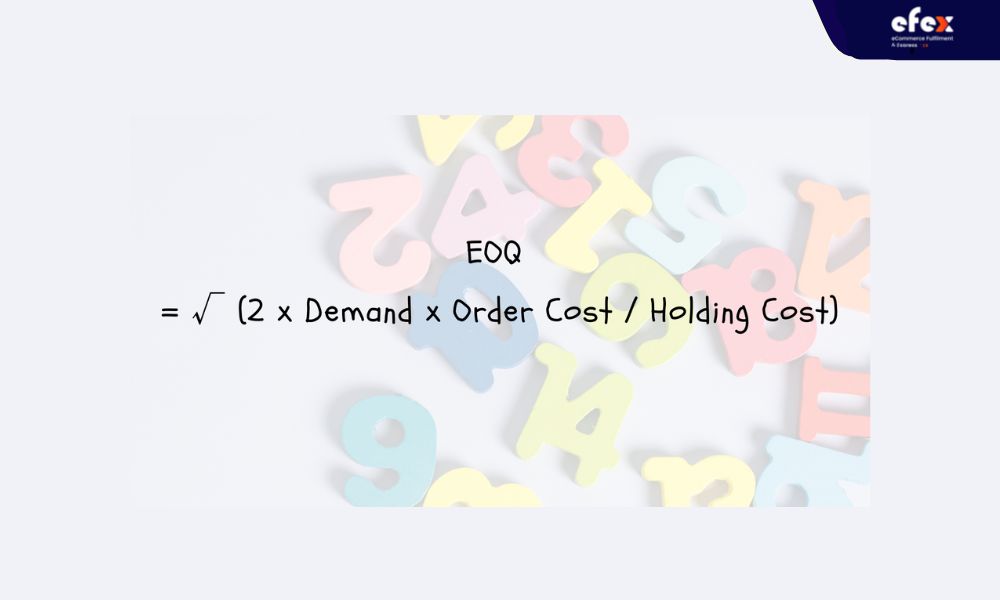

Next, you should determine the economic order quantity (EOQ) for each of your goods. That is the best quantity of a product to maintain on hand in order to meet demand without having to retain any extra inventory. The formula for determining your EOQ is as follows:

EOQ = √ (2 x Demand x Order Cost / Holding Cost)

Fortunately, there are several options for organizations with overloaded warehouses to cut inventory without facing significant losses.

Here are the top 10 effective methods to reduce inventory in 2023 you should know:

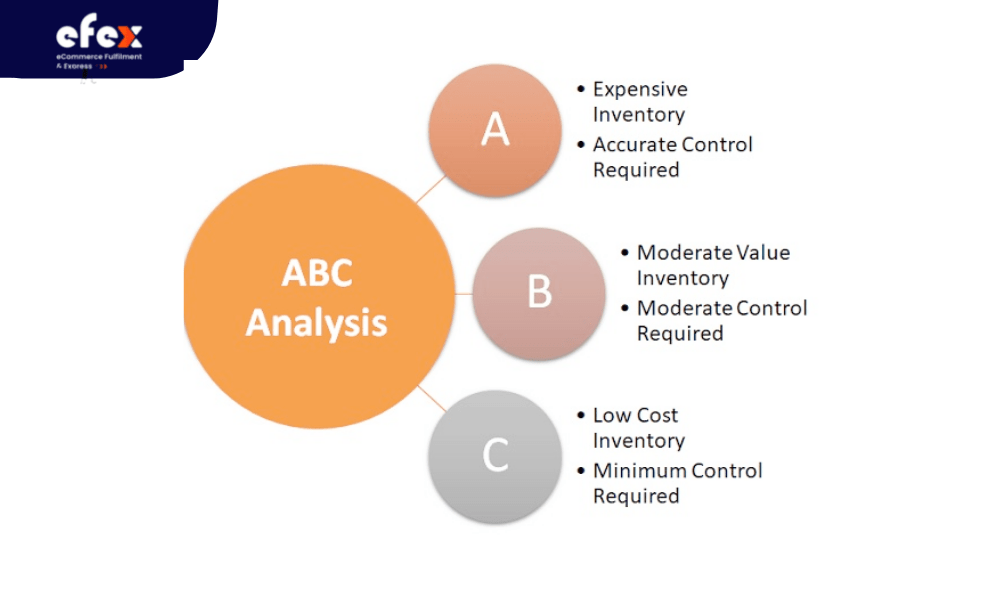

An ABC inventory analysis is a method of inventory management in which you divide your products into three categories. These groups can help you determine which goods provide the best return on investment and have a higher sell-through rate. Furthermore, it will identify your least effective goods, allowing you to avoid ordering so many products that aren't adding value to your bottom line.

We hit on this in the previous example, but an inventory reduction sale is one of the finest ways to get rid of inventory that is about to expire. You can run a buy one, get one free promotion, offer discounts based on minimum order quantities (MOQs), or something else entirely. Just make sure to take advantage of all of the eCommerce marketing platforms available to you in order to attract as many clients as possible.

Running sales too frequently can raise demand variability, cause warehouse troubles, and even generate a bullwhip impact in your supply chain, which may seem contrary to the argument above. It also makes many shoppers wait until your next offer before making a purchase. Instead, offer only seasonal deals to stay competitive. If you find yourself struggling to hold sales on a frequent basis to clear out unsold inventory, you should examine your demand forecasting and ordering methods.

Individual, but related, products are wrapped and sold as a single bundle in product kitting, an order fulfillment approach. These packages can be centered on a theme or comprise a single popular product together with a few lesser-known products. It's a terrific strategy to get rid of a lot of inventory while maintaining a healthy profit margin. You can also use a subscription box business strategy to increase your participation in product kitting while also generating recurring revenue.

No one likes having to wait for deliveries, especially when meeting demand requires prompt delivery. Always keep track of how long it takes to receive goods you've bought and observe how this affects your customers. Unsold goods might pile up in your warehouse if you frequently run into back-ordered products or lose sales owing to insufficient inventory. Discuss with your suppliers to determine the source of the disconnect so you can solve warehouse issues and meet demand.

Inventory cost reduction will open up warehouse space, reduce overhead costs, and optimize your fulfillment process. Examine your present warehouse procedures thoroughly, leaving no stone left. You can utilize any of the tactics listed above, or search for an inventory reduction plan template. Besides, you can also use the JIT inventory model to identify areas for improvement and lower warehouse expenses.

Before lowering inventory, it's critical to analyze all of the products available and determine whether any should be terminated. High demand unpredictability, increased production and holding costs, and extended lead times are all key threads of these commodities. By getting rid of those things, you'll be able to minimize your overall inventory and costs.

When it comes to inventory control, accurate demand forecasting is essential. This is a difficult factor to handle because demand fluctuates regularly. Companies that want to lower their inventory levels should invest in an integrated system that allows for demand forecasting. This way, they can only buy the ingredients they need to create the proper amount of items.

Inventory cost reduction will be improved by reducing lead times in supply chain such as manufacturing and supplying. Your materials holding costs will be reduced if you choose suppliers with shorter lead times. Furthermore, in order to reduce overall production lead times, you will need to store WIP goods for shorter periods of time.

If there are some situations, of course, excess inventory, that made you nervous, you're probably trying to reevaluate your inventory management. Inventory reduction is extremely good way to save money, reduce profit loss, and free up cash for other company activities. To sum up, the objective of smart inventory management is to run a more effective and automated organization with less inventory so that you can well prepare for the future. In business, be flexible and only invest in what you really need.