![[Detailed] SAP Warehouse Management Process Flow](/_next/image?url=https%3A%2F%2Fstrapi-efex.ichiba.net%2Fuploads%2Fsap_warehouse_management_process_flow_765493ecb1.jpg&w=1920&q=100)

More Helpful Content

SAP warehouse management system ensures that items move smoothly through the downstream supply chain, which is critical for assuring customer satisfaction and increasing profit margins.

If you are still considering whether to apply the SAP warehouse management system to your warehouse, just read this article as it will describe to you the most detailed SAP warehouse management process flow and also the high functionality of each process.

Warehouse management is completely integrated with the SAP R/3 system. Transactions initiated in other SAP components activate WM tasks, which in turn cause physical transfers inside the warehouse.

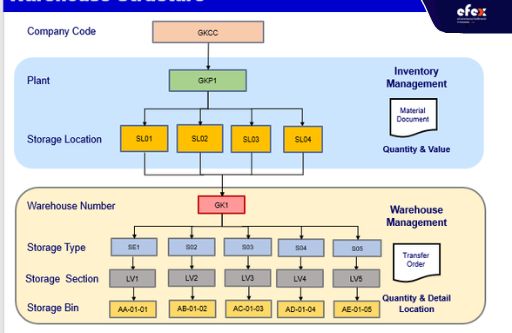

SAP Warehouse Management allows us to build and map the physical warehousing structure in the System, handle goods movements like stock transfer, receipts, and issues, and manage stock inventory changes at the storage bin level in the warehouse complex.

👉 Read More: Sap Extended Warehouse Management: Overview And Benefit

👉 Read More: Sap Warehouse Management Organization Structure

Warehouse Management is integrated with the modules of Sales and Distribution, Material Management, and Quality Management. The basic material for the material movement will be created in either the SD, QM, or MM modules.

The MM module generates the foundation document for goods receipts from vendors as well as other plants. The MM module also generates the foundation document for goods issuance for production or other plants.

The QM module generates the basic document for returning the item to the vendor during manufacturing, as well as during the GR quality procedure and online inspection.

The delivery document is prepared in the SD module for the material removal from the warehouse for the product delivery against the sales order. The basic document is prepared in the SD module to handle the content returned by the customer.

Inventory will be managed at both the storage site and bin levels in inventory management and warehouse management. RFID and barcode reading capabilities are also included in the WM module. These may be investigated and implemented as a separate project in the future.

When you use SAP Inventory Management (MM-IM) to manage your warehouse goods, you control the quantities and values of stocks in several storage locations.

The activity or movement of the warehouse process in a warehouse is defined by a warehouse process type. It is allocated to each warehouse job document and deals with each warehouse operation such as packing, good receipt, and good issues.

The WMS has been completely integrated into the SAP environment. Physical product movements in your warehouse are caused by business activities that you initiate in other application components.

If FG/SFG Materials are in stock in the warehouse, we can restock the Customer Order. If not, we must go for in-house manufacturing if it is available by issuing RM or SFG Material to be transformed to FG Material and then placed within Warehouse stock. Now, we can issue against a Customer Order.

Even if RM or SFG material necessary for in-house production is not accessible in the warehouse, we must outsource it, which means we have to obtain RM or SFG Material from the vendor for production.

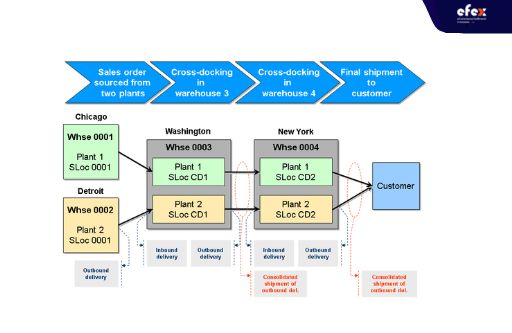

The need is either manually or automatically triggered in this case. It relies on the business process and the needs of the customer. Or obtaining FG material from the vendor and issuing against customer order. Here in-coming stock is not receipted or PGRed, but rather placed at the cross-dock area and monitored through the Cross Dock Monitor, and if an issue is required, it is directly issued to the customer.

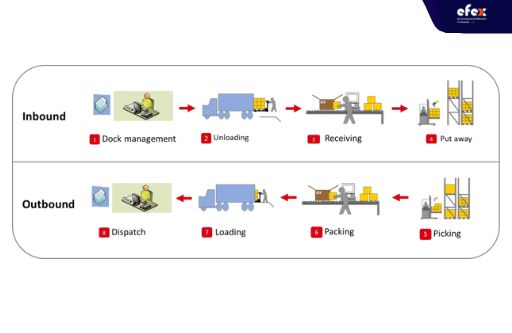

When a truck comes to the warehouse gate, the warehouse employee will verify the delivery for PO/STO/Sub-con PO/Returns PO according to the situation.

The delivery is accepted if all of the amounts are correct. Otherwise, the package would be refused and returned to the sellers. Once the warehouse employee has accepted the cargo, he or she will direct the warehouse staff to unload the items off the truck.

During unloading, the warehouse manager and crew will manually examine the label- SSCC/Details, the amount delivered, defects, and so on- in the stock material. If nothing is incorrect, the manager will sign the transit acceptance paperwork. If there are any issues, he or she can call them out in the document and also notify the purchasing team in charge to further speak with the vendor.

Then he or she will send a node to a truck driver to move the truck out of the warehouse, and the stock will be moved to the unreceived dock area. At this point, we will need to build a GR document using the PO as a reference. If necessary, the label will be created and applied to the pallet. If not, we must scan the item immediately to determine the quantity received.

After inputting the incoming quantity and delivery note number, post the IBD. We must decide if a QI and QI label or a lot number is necessary. Print the QI label and affix it to the pallet if necessary. We now have TO confirmation for inbound stock put away.

Following that, the system will scan every line item in the TO, beginning with the top line 1 and progressing through the TO line items to the conclusion. It will scan the barcode label attached to the pallet and display the substance and amount. The machine will also scan the bin and storage to check the TO. Finally, the stock has been validated.

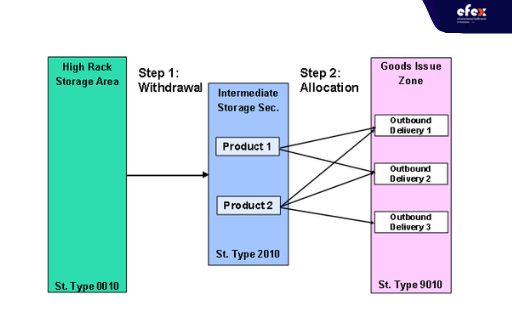

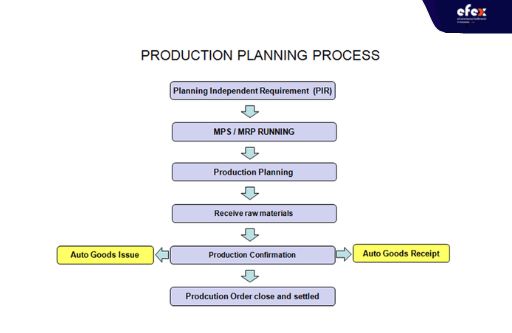

When an order is established, we may view its specifics in the warehouse management picklist page in order display, including the production bin, material staging type, and material amount required. When we release the manufacturing order, the system will undertake material staging.

Following that, the system decides the sort of material staging to be employed depending on the control cycle as well as the production storage bins where the material is staged. Because the system selects auto staging, the auto TR is created by default. We may also use manual material staging, which is determined by BP.

Generally, you will be asked a question at this point. How many requirements will be produced? The quantity of production orders for which TR is produced determines this. It is again dependent on the quantity of allocated PSA for release order parts. You may construct the TO for the staging materials in SAP warehouse management after checking the TR creation with the TR display functionality. Depending on BP, you will once again have the opportunity to build TO auto in the backend.

You may now stage items depending on the TO and transport them to the production storage bin or storage type-100. For material consumption, you can submit GI. You will have two options at this point: manual backflushing or automatic backflushing.

We cannot tell whether the method is superior to the other, but if the manual method is chosen, we must input the production order number in GI and manually modify the stock in IM and WM based on the current stock position to decrease material consumption after the FG Assembly.

👉 Read More: All Cost To Rent A Warehouse In 2023

The auto backflush system, on the other hand, decreases the material quantity in the production storage bin without the need for TR or TO formation. Consumption is likewise not uploaded until production is validated since the system will only react when the quantity of consumption is known.

The benefit of using the WM-PP interface is that we can quickly move products from manufacturing into the warehouse. On confirmation of the production order, the system posts a good receipt in IM for the FG material and creates a quant in the WM-in the interim storage area for goods receipts from production. When manually posting GR, you can utilize IM movement type 101 for goods receipts from manufacturing. This IM movement type is given WM movement type 103.

With the GI posting, the FG content is stored in the WM's interim storage type 901. A PCN is generated by the system. Based on the TR, we establish a TO in the WM for the putaway. If QM is enabled, it will undergo a quality check before being released in QA32 for both auto and manual GR from the manufacturing process. For each GR or partial GR, the system generates a new inspection lot.

If the product is not PGRed and is at the unloading dock, the system will scan the delivery and collect the PO number. If it is handled by the HU/SN, the system looks for HU and SN information.

If the HU label is necessary, the system will print the label and affix it to the pallet or the material. If this is not the case, the system will scan the material code.

The system then determines if this material is Cross Docking linked or active by checking the material master data/indicator in the PO. The system will now seek the quantity, and you must input it exactly and upload it.

Then, automatically, TO’s are generated to transport the material to the cross-dock region. Your next task is to transport the merchandise and confirm the TO. The materials are now items that have been issued to the client.

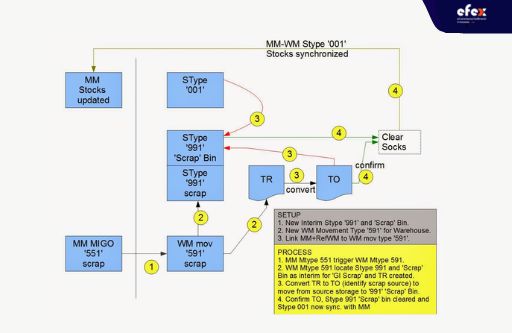

Scrap in SAP refers to materials that have reached the end of their useful life, have been damaged, cannot be used, or cannot be remanufactured. Most firms generate trash throughout the manufacturing or assembly process.

Movement Type 551 makes use of scrap material. For a variety of reasons, you may come across things in your warehouse that are damaged or unusable. This is a common occurrence during picking or physical inventory. These items must be eliminated since they are seldom resold.

If Management needs to examine the quality of materials that are already in unrestricted stock, use MB1B and Movement type 322 to shift the Material to QI stock type. We may do a QI inspection if Quality Inspection is necessary. If all is well and no defects are discovered, return to stock using the 321 movement type. However, if a flaw is discovered or the quality is not up to standard, we must transfer it to the maintenance center or department for repair or return it to the vendor.

If a quality check is not necessary, we can use the 553 movement type in MB1B to submit to junk.

Another reason for scrapping is material deterioration. When there is material damage during the warehouse material handling process, you must first examine the degree of damage in the material. If it is repairable and reusable, we can give it to the maintenance or fix department or the vendor to reprocess. If not, we may remove it. With movement type 551, we may utilize reason code in MIGO or MB1A.

Some customers establish a scrap or non-reusable limit for specific materials that are not suitable for further use. You must verify the status in MM-IM to see if it is outdated and unusable, and you must also notify the material master team to keep the reason for scrapping.

After learning about the SAP warehouse management process flow above in a detailed way, we believe that you partly understand the importance of warehouse management and the reason why many firms have resorted to cutting-edge software solutions such as the SAP warehouse management system (WMS) to improve stock management, order fulfillment, warehouse layout, planning, and monitoring operations.