More Helpful Content

Whether you run a business with an entire manufacturing unit, or you trade and supply, you'll need warehousing space to keep track of your raw materials and other supplies. The administration of stores or inventories is referred to as warehouse management, which is a powerful branch of supply chain management, from the days of accounting stocks in arithmetical means to the present day of robots and creative system software inputs.

We'll discuss SAP Extended Warehouse Management and how it can help with warehouse management in this post.

SAP Extended Warehouse Management (EWM) is a component of SAP's Supply Chain Management (SCM) suite of products. It is utilized for efficiently managing inventory in warehouses as well as supporting product movement processes.

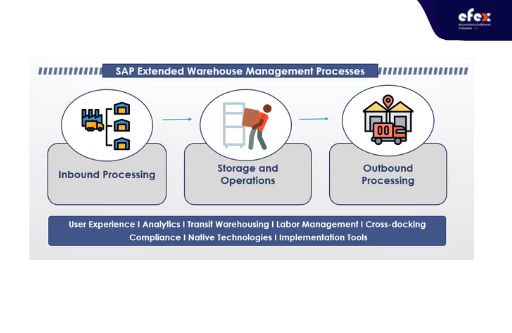

SAP Extended Warehouse Management enables the business to manage inbound and outgoing warehousing operations, as well as the flow of items inside the warehouse. Incoming and exiting materials, product reception and issuance, customer order fulfillment, and transportation of goods are the main processes involved in warehouse management. There is no requirement for warehouse management to handle products if a business does not keep any goods.

👉 Read More: [Detailed] Sap Warehouse Management Process Flow

👉 Read More: Sap Warehouse Management Organization Structure

The inbound process entails storing products in a warehouse and determining their location, whereas the outbound procedure is collecting up the products. When a material is kept in a storehouse, it is placed in a storage bin, where its current location can be identified. All commodities movement is regulated by a warehousing management system using SAP EWM, and you have the tools to supervise warehouse activity.

In the Warehouse, you can also handle extra functionality such as batch number generation, serial number generation, vendor management inventory, value-added services, and resource optimization. SAP warehouse management system helps you to efficiently manage not just the number of products in your warehouse, but also other important operations and shipments.

Inventory management is the absolute opposite of SAP Warehouse Management. The quantity of products in storage is reported by inventory management, but the exact location of the commodities is unclear. Warehouse management is concerned with the transportation of products and the tracking of their physical position as documented by specified papers.

SAP EWM is an element of SAP Supply Chain Management, and it works similarly to a warehouse management system, but it has more powerful and advanced functionality for managing critical warehouse tasks.

SAP Extended Warehouse Management is akin to Warehouse Management; however, it includes additional capabilities such as putaway, picking, Warehouse structure, RF framework, and more flexible choices for managing warehouse tasks. In SAP EWM, you may add additional features such as a resource, activity area, labor management, as well as work centers that weren't available in WM.

The key features of warehouse management with SAP EWM are listed below:

When considering whether or not to deploy EWM, businesses should keep one word in mind: "robust". The EWM is capable of managing the most basic to the most complicated warehouse operations, as well as giving extra capabilities that WM lacks. For instance, EWM can offer:

From a technological aspect, SAP has given migration solutions to transition from SAP WM to EWM fairly simple, and the principles are similar enough that the client's learning curve is minimal.

However, for individuals who are accustomed to WM and are hesitant to migrate to EWM, the following factors may help you get closer to being implementation-ready:

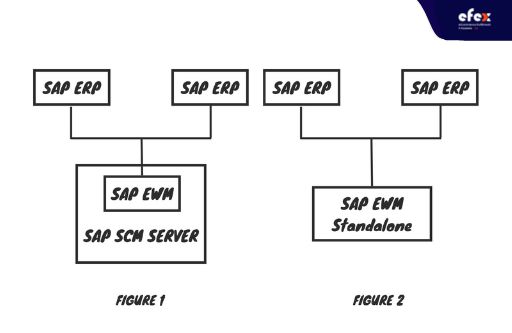

SAP EWM can be installed on an ERP server or as a standalone application in the Supply Chain Management environment. SAP Extended Warehouse Management is coupled with ERP to get transaction and data management, and it also needs CRM integration to use functions including slotting and availability checking. It is treated as a distinct program that runs on the same server as the SCM apps. SAP EWM can also be operated in its own SCM environment, which is better for performance.

The deployment options for SAP EWM are shown in the graphic below.

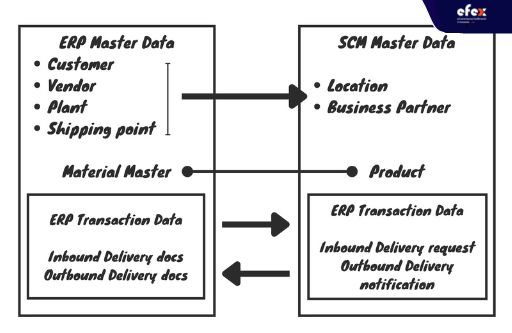

For the transmission of transaction and master data, SAP ERP and EWM are tightly connected. There are two methods for communicating. Core Interface (CIF) is one of the most prevalent communication methods between SAP SCM and SAP Advanced Planning and Optimization APO. Material, customer, and vendor master data from ERP systems are sent to EWM systems via Core Interface CIF connection.

A distinct integration mechanism is employed for the communication of transaction data (inbound or outbound delivery documents). This paradigm makes use of iDocs or RFC (remote function call) queues.

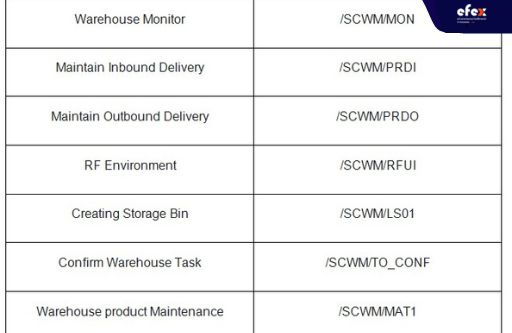

Sign in to the SCM system and go to the SAP menu's Extended Warehouse Management node. To manage fundamental operations in Warehouse management, you must utilize a variety of transactions.

👉 Read More: All Cost To Rent A Warehouse In 2023

A smart warehouse must be able to adapt to changing business conditions fast. You will be able to handle a large volume of items and perform agile processes with digitalized and expedited warehouse procedures using the modern, versatile SAP Extended Warehouse Management.