More Helpful Content

Before learning about the two-bin Kanban system, let’s take a look at the Kanban method to know what it is. The Kanban method depends on visual signals to initiate and terminate the workflow. The unfilled bin serves as the trigger in the two-bin system. In the restocking form, this signal is reversed. The cycle is reset once the worker turns the bins.

As a general rule, employees should not distribute things unevenly. Furthermore, they must place just the predetermined number of items in order to ensure implementation consistency with planning. Kanban supports the use of visible indicators to increase production movement and efficiency, making it a perfect strategy for physical product makers.

A Kanban two-bin system is one of the most well-known tools in Kanban production. The two-bin system is a simple but effective method of keeping an ample supply of high-demand commodities near the manufacturing line. This strategy combines practical advantages with strategic efforts to protect commercial interests. This idea, which is part of the Toyota Production System, strives to reduce redundancies in the process of production.

The two-bin system is a system that employs two physical bins to track inventory, typically of small but vital items. It is a basic pull system with two spinning bins supplying the pieces.

👉 Read More: What Is Order Picking In Warehouse: Importance And Method

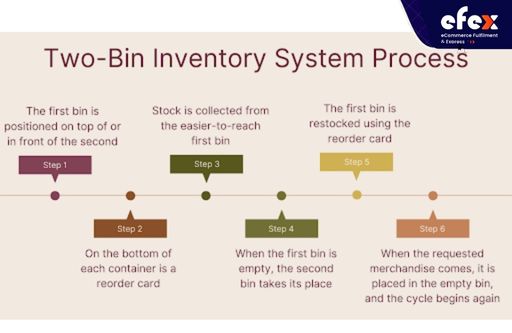

The technique works simply by providing workers with two plastic storage bins containing goods that they may draw from to satisfy requests or supply multiple departments. The number of goods placed in the bins is determined by the rate at which the individual products are consumed. The two-bin system’s goal is to minimize surplus inventory throughout the manufacturing cycle and to match stock levels with actual consumed, all while identifying any bottlenecks in the supply network.

One of the most difficult obstacles that businesses confront is effectively controlling inventory levels. Lack of inventory can lead to missed future sales and losing ground to the competitors.

Overstocking, on the other hand, raises the risk of spoilage, damage, theft, and falling subject to swings in need. It also means higher storage costs and longer durations between recovering money from purchased things and reinvesting it in the company.

The two-bin inventory control system does exactly what it says, which manages inventory using two bins. The idea behind a two-bin arrangement is that operators will serve from one bin while keeping reserve supplies in the other. When the components of the first bin are depleted, the operator will begin serving from the reserve inventory while signaling that additional inventory is necessary.

The signal might be as basic as the color of the bin or as complex as RFID signals delivered to receivers and automatically placing a purchase with suppliers. When the next batch of inventory arrives, it is then placed back into inventory for the operators to work from once the current batch has been depleted.

The two-bin method establishes a cycle, refilling when needed while building a demand for the following batch. If executed effectively, this means you are near to your needs. It is a fundamental strategy used to guarantee that businesses minimize these risks and always have enough stock to fulfill demand without going beyond. This technique is widely used in several businesses that include industrial processes and is also useful for hospital inventory control.

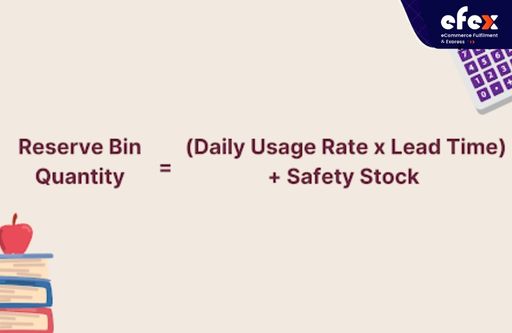

The quantity of inventory to store in the reserve stock bin is calculated by multiplying the daily consumption rate by the lead time and adding the safety stock amount. Here is the formula:

Two-bin inventory control is typically utilized low-value commodities that may be ordered and stocked in bulk and are kept in the manufacturing area instead of in the warehouse. To keep greater control over the company’s working capital investment, more costly inventory goods are handled via a perpetual inventory system.

Like any other company process, you must consider the benefits and drawbacks of the two-bin system.

Because of its advantages, a large number of firms have used it in one or many processes. The major reasons for its success are its high reactivity, simplicity, and efficacy. Below are its benefits that are relevant to practically all of the firms who use it:

A decrease in inventory levels is a positive side effect of utilizing a two-bin system since only keeping the amount of inventory you need implies you do not have funds tied up in inventory that will not be used for a couple of weeks or possibly months, while also promoting traceability of components through bulk control which is stored within every bin.

When all of the preparation is completed, it is critical to monitor elements that may impact the two-bin system, like manufacturing surges that may result in increased demand for inventory.

Besides, this system does not require a computerized database. The re-ordering procedure is instead dependent on a visual evaluation of bins. This is highly helpful when a company maintains huge amounts of low-cost items and does not wish to deal with inventory cycle counts on a regular basis.

However, these advantages come at a cost. Adding extra parts to each bin can postpone the order process even further, slowing down the complete operation. This is where two-bin systems frequently fail. Therefore, it is critical to perform the calculations before adopting any type of inventory management procedure to guarantee that the proposed system will properly satisfy the demands of your supply chain.

Moreover, inadequate planning can cause a two-bin system to fail. It is frequently recommended to analyze the product’s demand and make sure that all reserve batches include enough product while taking the following batch’s lead-time into account.

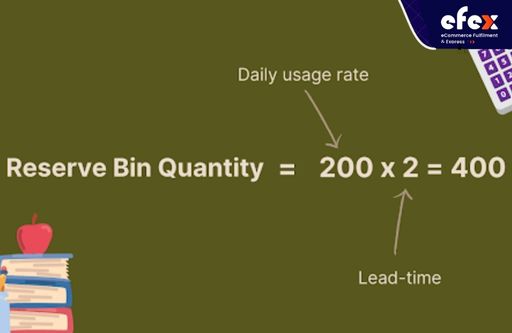

WL is a small manufacturing company that uses a variety of types of batteries to assemble into its electric products. Yellow batteries are only one of the numerous goods it purchases from outside vendors. It utilizes about 1,000 of them every week, or 200 of them per day, with a two-day lead time, which is the time between the start and finish of a manufacturing process.

Depending on the initial calculation, the reserve bin at the company should include at least 400 yellow batteries to meet predicted consumption during the two-day lead time.

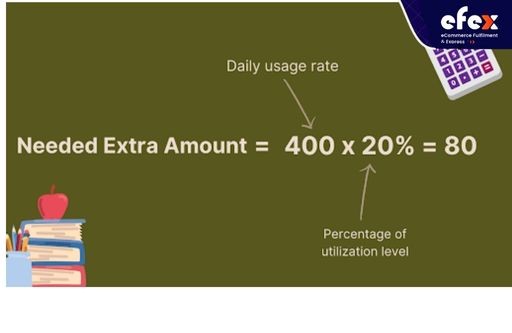

Furthermore, the company expects that utilization levels to vary by up to 20% from the average level of consumption. Thus as a preventive step, it has added some extra yellow batteries to its reserve storage bin which is 80 batteries.

As a result, there are 480 batteries in total reserve inventory.

This reserve may come in useful if the demand rise and manufacturing rates rise as they used to in the past.

👉 Read More: All Cost To Rent A Warehouse In 2023

If your company manages a high amount of tiny, easily accessible items, a two-bin system might aid in the establishment of an effective and successful inventory management system. But if you are working with larger, more expensive items or parts that necessitate long lead times, a different solution may be more appropriate.

There are many factors like shifting demand, lot amounts, minimum orders, and others that can have an influence on the exact order needs for your Kanban system to work properly. Just remember that it is critical to understand the particular demands and issues influencing your supply chain before installing any type of inventory management system.