More Helpful Content

Improving inventory management is one of the best strategies to increase revenue from eCommerce. Even if you believe you have an excellent inventory management system in place, a few modifications can improve your processes and revenue. Thus, let's take a look at these 15 useful tips to improve inventory management to optimize your managing inventory more!

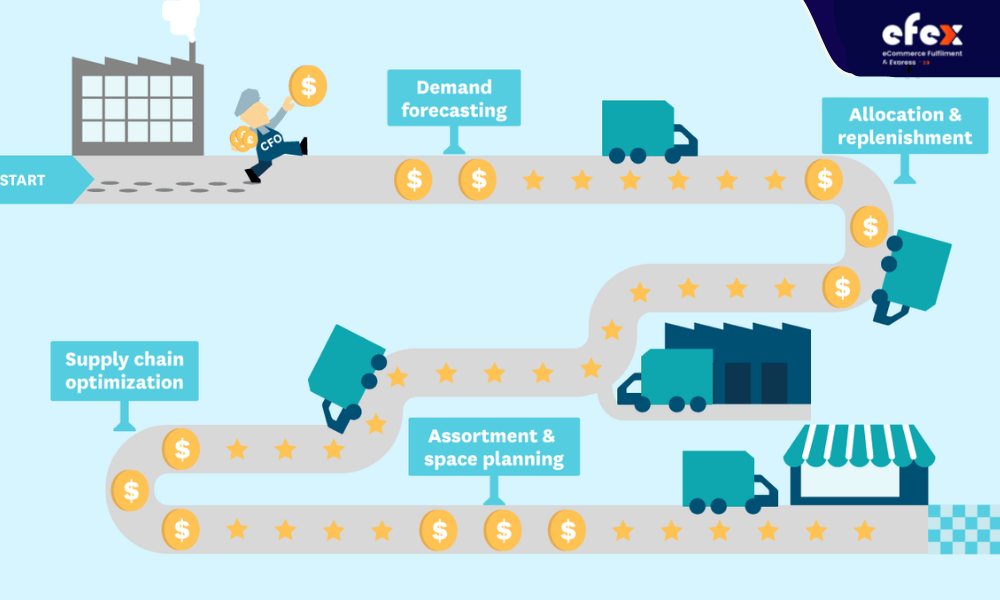

Inventory management includes all procedures that affect your inventory, from ordering and receiving goods, to storage and use to order fulfillment. This effort requires a significant amount of data, such as your current inventory and sales volume. As a result of this data collection, inventory management has become an essential component of market demand forecasting. The more accurate and valuable this information is, the better the inventory management will be.

Simply put, understanding your inventory and how to manage it will help your company meet the requirements of today while growing to meet tomorrow. Now, let's look at five techniques that have been selected to help you capitalize on growth prospects.

If a customer is very interested in a pair of shoes that you sell, unfortunately, there are no matching sizes in your inventory. Worse still, the manufacturer supplies your shoes with made-to-order, so it will take you more than a week to get the right shoes for the customer. So you lose another customer.

However, it would also be unreasonable to spend most of the money and space of the warehouse on shoe storage. There is no ideal answer to the challenge of combining shipping costs with the requirement to have enough supplies when orders come in - how to get enough stock to sell but not too much.

👉 Read More: 15 Best Practices For Inventory Management

There is no such thing as a perfect inventory level, but maintaining a minimum inventory level is a great solution adopted by many businesses to achieve this balance. Setting a minimum inventory level for each item allows you to replenish the new stock in time before supplies run out. Calculate your minimum stock based on sales data and the time it takes to get a new item.

If a customer is very interested in a pair of shoes that you sell, unfortunately, there are no matching sizes in your inventory. Worse still, the manufacturer supplies your shoes with made-to-order, so it will take you more than a week to get the right shoes for the customer. So you can lose another customer. However, spending most of the money and space of the warehouse on storing shoes would also be taboo.

There is no ideal answer to the challenge of combining shipping costs with the requirement to have enough supplies when orders come in - how to get enough stock to sell but not too much. There is no such thing as a perfect inventory level, but maintaining a minimum inventory level is a great solution adopted by many businesses to achieve this balance.

Setting a minimum inventory level for each item allows you to replenish the new stock in time before supplies run out. Calculate your minimum stock based on sales data and the time it takes to get a new item.

Not even the strictest inventory management systems can claim that nothing bad happens. Let's say you supply strawberry jam by the bottle and also in the case of 12 bottles each. You deliver 1,000 bottles and 100 cases to your fulfillment facility and start selling products. And you sell very quickly, but you still have 500 bottles of strawberry jam.

SKUs for individual bottles differ from case codes. Orders keep coming in faster than you can supply more boxes of strawberry jam to your fulfillment facility. What will you do next to improve inventory management? Let's scroll down to read another way.

When your inventory becomes unmanageable, your company will be affected in a variety of ways. Your inventory is not only unprofitable, but it also loses value as it ages, ages, and becomes harder to sell. That's not the only cost of the goods lying on the shelf. In addition, there is an expected component of a significant loss to inventory-related cash.

The revenue you spent on inventory could have been better spent on advertising or website improvements, which would increase sales and therefore improve your business income. your online store. Because you are not physically present at the warehouse to fulfill orders every day, it is very easy to lose track of this inventory.

Besides other mentioned above to improve inventory management, one of the most egregious parts of inventory management is that it no longer exists. Collapsing is a widely used method when damage, loss, breakage, and petty theft occur: all reasons why a pair of shoes might not be on the shelf. Most complete systems are miniaturized.

👉 Read More: 15 Techniques Of Inventory Control You Need to Know

This indicates a high probability that your inventory management system is faulty: products that are not in stock are actually reported to be on the shelf. Maintaining the proper level of inventory isn't the most exciting aspect of running an eCommerce, but it's an area where the work invested can pay dividends and provide you with a source of cash significantly.

Another ideal way to improve inventory management is inquiring for assistance from suppliers, which is an excellent strategy to improve inventory management. The vendor can authorize access to the distributor's inventory data via a Supplier-managed list. Purchase orders are created by suppliers whenever they are required. Vendor-managed inventory control is used by dispersion firms to eliminate data entry errors, allowing them to better manage the timing of purchase orders.

Hiring a specialized inventory control manager is another practical suggestion to consider when controlling your inventory. An inventory manager is responsible for improving inventory management by making sure the company's products are available on the ground as well as in transit. They are also experts in handling adjustments and modifications, such as return orders. They can also ensure that goods have been received while applying an inventory reporting system.

Delivery time is the amount of time it takes for a re-ordered product to arrive. As you know, it takes different times for suppliers to deliver their items after receiving an order. Generating lead reports to get detailed information on how long it takes to replace your inventory is a useful technique for inventory management.

Having a large amount of inventory adds to your costs because of maintenance fees and the space they take up in the warehouse. Another important tip is to carefully define a company's inventory requirements. You should strive to keep annual inventory lists to a minimum and avoid wasting resources on items that don't sell or never sell.

Most top-level organizations have well-developed monitoring systems that make rotation monitoring more accurate. These inventory monitoring systems are available in a variety of formats, from desktops to applications. These applications offer comprehensive inventory control, allowing business owners to manage and arrange their productivity levels, as well as do monitoring in storage areas or distribution centers.

According to the 80/20 rule, 80 percent of revenue comes from 20 percent of inventory. It also claims that 20% of the products available account for 80% of the entire gross profit. As a result, firms must concentrate on large commodities that are circulating in their inventory. Make sure you have a backup supply of such things on hand, as well as ample storage space. Don't squander valuable storage space on items that don't sell well.

👉 Read More: 15 Vendor Management KPIs You Should Know

You should also work on making the purchase process for that product as simple as possible for your consumers and maintaining it in an easily accessible location.

There is a lot of information to evaluate and analyze when it comes to wealth management. It is very important to pay enough attention to any merchandise that does not turn around. You want to divide your inventory for each product line due to the evolution of the inventory system.

👉 Read More: 20 Important KPIs For Inventory You Need to Notice

So you should keep track of sales and inventory for each product line. You should also focus on sales margins. Track your gross profit per product line so you can see which products are bringing you the most sales. It is also very important to evaluate your data safety.

The amount of additional inventory in your warehouse held in the event of a shortage is known as safety stock. This can be beneficial in the event of unforeseen supply and demand spikes, as well as other unforeseen situations.

It all depends on how much of the most important goods you can deliver to your employees. It's important to keep your warehouse tidy and avoid bringing in potential merchandise. Sidell highlights the need for inventory visibility in inventory management. You should know where your cargo is, whether it's in transit or waiting to be dispatched from another location. Another key piece of data for inventory tracking is the ability to organize your inventory into items that may be leftover.

Using the ABC method to maintain inventory control is a reliable method for improving inventory management. With this method, you will have enough information about the warehouse to know which goods are being bought the most by customers. They will then divide these products into three groups.

Every company with a high-profit value can track multiple units as they progress through different functional phases. By building a system capable of tracking "work in progress," companies can update and modify order quantities before inventory is depleted in sales and turns.

Knowing how to improve inventory management will be very helpful to you as a business owner. This will help you understand the current state of your inventory, understand what you are doing well and what needs to be modified and replaced in order to optimize profits.