More Helpful Content

Inventory management is critical for any business looking to improve its merchandising process. Having the appropriate system in place enables better product tracking, more organization, more accurate data and reporting, and enhanced warehouse efficiency, contributing to increased income.

Stop letting inventory problems eat into your profits. These 15 proven control methods will transform your approach to stock management, helping you minimize costs, eliminate waste, and ensure you always have the right products available at the right time. Whether you're struggling with overstocking, stockouts, or inefficient warehouse processes, these industry-tested practices will give you the framework to achieve inventory excellence and drive sustainable business growth.RetryClaude can make mistakes. Please double-check responses.

Beginning with your available data is one of the inventory control best practices you should know. Smaller companies used to find it prohibitively expensive to use massive volumes of data efficiently. Today’s most effective methods revolve around data collecting, aggregation, and insights from the only source of truth.

The inventory control software has altered the field by allowing small and medium-sized businesses to quickly create that only source of truth and profit from crowdsourcing learnings incorporated into the solutions themselves.

- See more:

Whether you are a major corporation or a small-to-medium-sized company, data-driven decision-making may assist you in getting results that will benefit your big or small business.

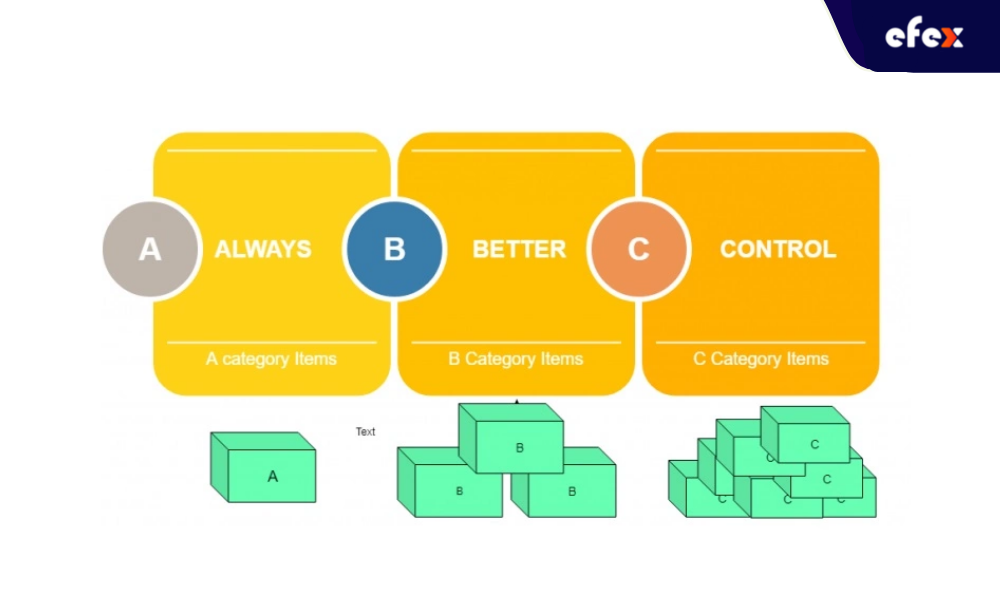

To optimize turnover, you must first determine which inventory to prioritize. Bear in mind that all inventory is not created equal. ABCs technique in categorizing inventory depending on their worth to your business. It is a twist on the Pareto principle: just 20% of all reasons result in 80% of all outcomes. When applying to inventory, you will get:

Align value with your company’s goals when assigning items to each inventory category. Although profitability is often the goal, growing market share through gross sales can also be a target.

Because there is no uniform norm with demand volatility at an all-time high, it is the reason why demand planning and eCommerce inventory management are difficult. Extensive product lines, different sales channels, promotional opportunities, price fluctuations, and external factors, such as seasonality, have made predicting future growth challenging, particularly when you depend on spreadsheets and go through large amounts of past data.

However, automated demand forecasting is now available to companies of all sizes due to clever inventory management systems.

Another in inventory management practices is workflow automation which is the process of systematizing a portion or all of a workflow in order to enhance efficiency and reduce human dependency. It uses technology to centrally manage a complicated network of interconnected working elements while eliminating the physical labor demand.

Automating a portion or the entirety of a supply chain offers enormous potential benefits, including freeing up your personnel while enhancing productivity and accuracy in supply chain management. Indeed, automation may boost global economic output by 0.8% to 1.4% of global GDP every year according to McKinsey analysis.

👉 Read More: 15 Useful Tips To Improve Inventory Management

Workflow automation is achievable for every business with the proper system:

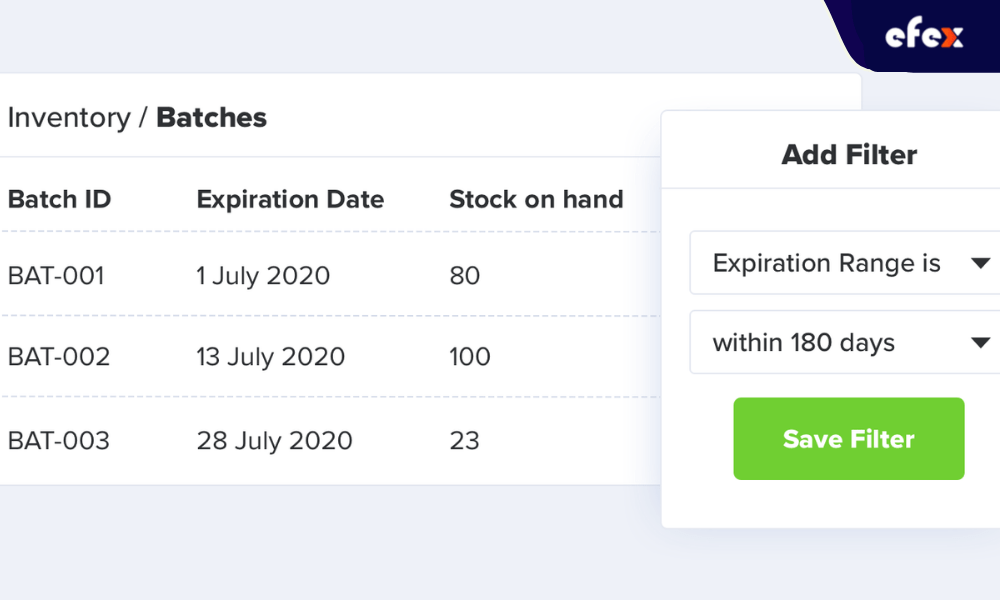

One of the best practices for inventory management you should not ignore is batching and expiration date monitoring, which lets you know where each “collection” of inventory has come from, where it is going, how much of it is remaining, and when it will expire. It is crucial for various reasons:

FIFO, known as first-in, first-out, is an accounting principle that states the first objects in your inventory are also the first to leave. You can also understand that the oldest inventory goes first.

LIFO, knowns as last-in, first-out, is the inverse of FIFO, which means the newest entries have precedence. If you offer perishable inventory, you should use FIFO. Otherwise, you will have ruined inventory, which can lead to a significant financial loss. LIFO is typically used for non-perishable items since it eliminates the demand to reshuffle warehouses or rotates batches. The only exception is if you offer both highly seasonal items and non-seasonal essentials, then you would require a hybrid strategy.

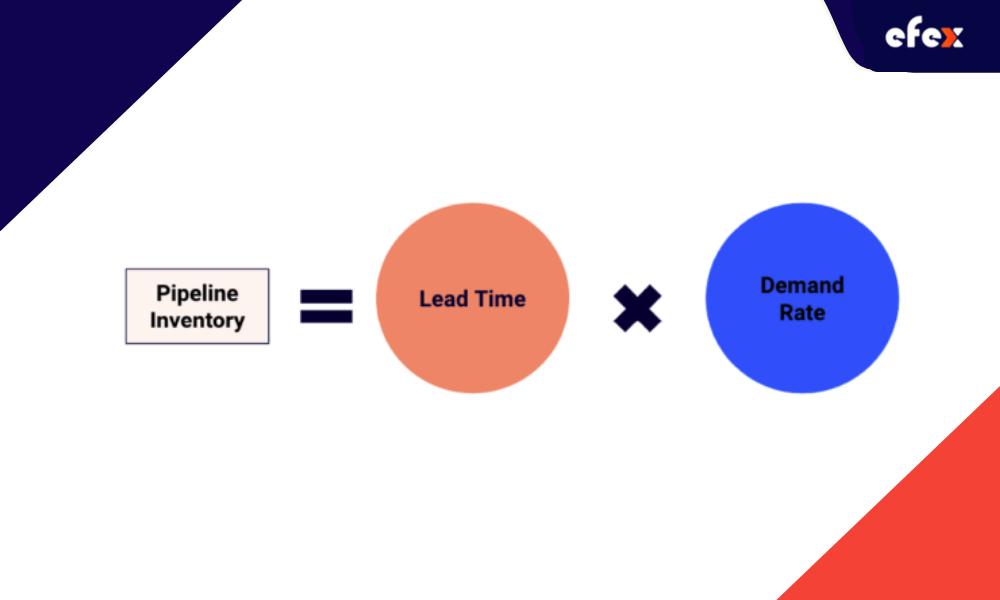

One of two safety strategies in management inventory control to avoid stock-out inventory is keeping your pipeline moving smoothly. Pipeline inventory shows products that have been ordered but have not arrived at their final destination yet.

For instance, if a wholesaler purchases inventory from a foreign manufacturer, inventory is considered the pipeline that is within the company’s supply chain during the shipping and receiving procedure. The optimal pipeline inventory may be estimated by multiplying the lead time by the demand rate.

The lead time is understood as the amount of time it takes between ordering and receiving goods, while the demand rate is the number of inventory sold between orders.

Decoupling inventory, also known as decoupling inventory, refers to products held aside in a production hiccup or halt. This inventory is sometimes referred to as safety stock. Decoupled inventory acts as a safety net, reducing the chance of a total halt in manufacturing if one or more components become unavailable and order fulfillment if stockouts occur.

It is essential to consider pipeline and decoupled inventory together to support achieving an accurate ratio between risk and expense. Maintaining that balance allows for efficient inventory management and long-term growth.

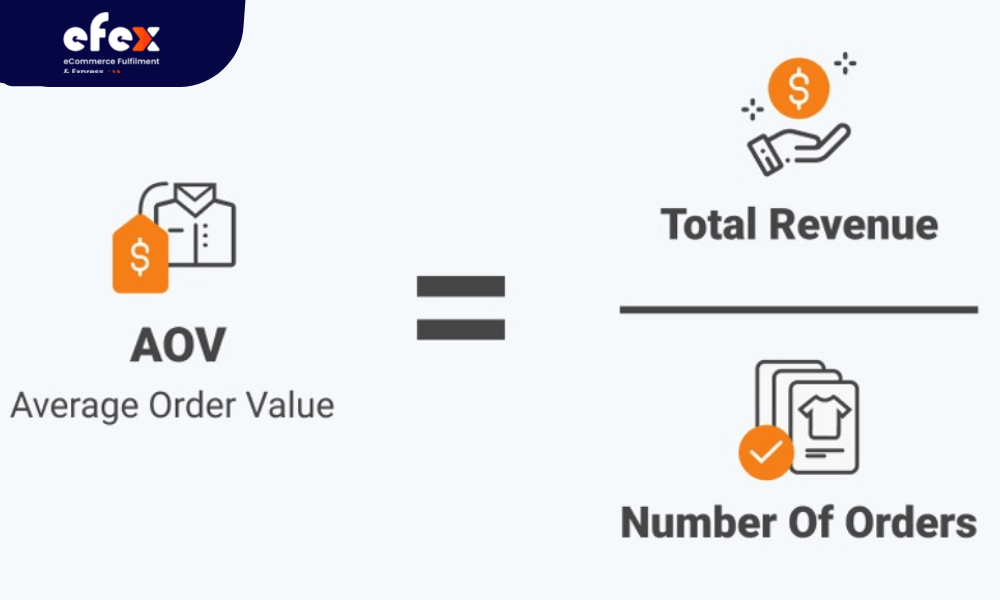

Kitting inventory is often known as “product bundling”, which is the practice of grouping, packaging, and selling distinct products as a single unit. When a bundled or kitted product is purchased, an inventory management system should instantly link each item to the sale.  AOV formula[/caption] Bundling may assist both B2B and B2C companies in the following ways:

AOV formula[/caption] Bundling may assist both B2B and B2C companies in the following ways:

The pick and pack process is a collection of procedures and inventory management tools that your staff uses to swiftly and efficiently fulfill client orders. Pick and pack processes are categorized into the following types containing picking discrete orders, batch sorting, wave selection, and zone selection. There are five approaches to enhance the pick and pack process for good inventory management:

Inventory KPIs assess your performance in a certain area over a set period toward a specified objective. They help avoid guessing by setting specific goals for each week, quarter, or year. You will have the necessary data to make smart strategic business decisions with them. There are six inventory KPIs to pay attention to:

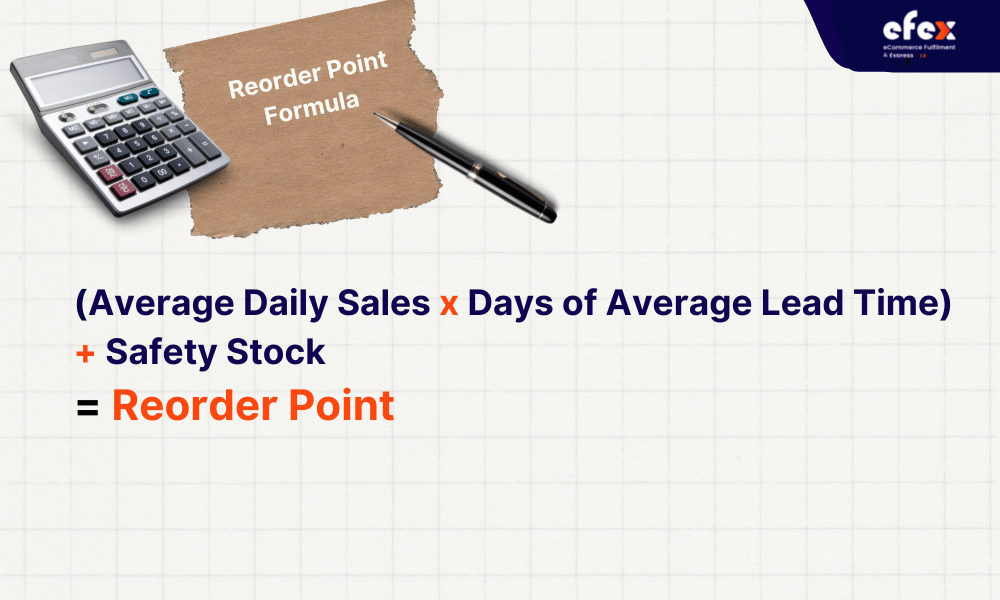

A reorder point formula indicates when you should order additional stock, which means when you have reached the lowest level of inventory, you can support before you need help more. You may avoid becoming a victim of market ups and downs by employing a tried-and-true mathematical formula to assist you in consistently purchasing the proper amount of inventory every month. It is known as a reorder point formula.

A safety stock inventory is a modest quantity of excess inventory that you maintain on hand to protect against fluctuations in market demand and lead times. If you do not hold a safety stock inventory, you may face problems like revenue loss, customer loss, and market share loss.

Safety stock is vital inventory management great method since it provides all of the following benefits: protection against unforeseen demand surges, stock-out prevention, reimbursement for incorrect market projections, and a reserve for longer-than-anticipated lead periods.

👉 Read More: 15 Techniques Of Inventory Control You Need to Know

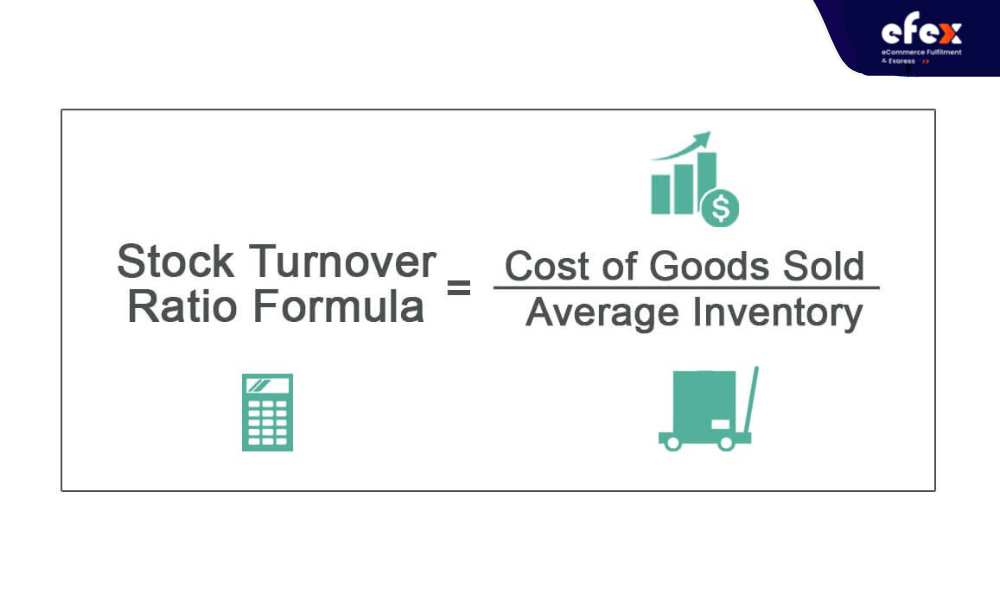

The inventory turnover rate measures how often your inventory is sold or utilized in a specific time, generally a year. Calculating your inventory turnover rate in inventory management can better understand the market demand for your items, the quantity of outmoded stock you may be holding, and what measures you need to sell or stock extra inventory based on your turnover rate.

You can consult these four ways to increase your inventory turnover rate, including playing around with price, disposing of outmoded inventory, estimating customer demand, and distributing inventory to different warehouses.

Streamlining your stocktaking is one of the good practices for inventory management for your business. Its process will support you in reducing the likelihood of costly mistakes being made by your team. A well-structured stocktaking process will contain all of the processes necessary to keep your workers motivated and focused while uncovering oddities and mistakes. These are a few clues to help you streamline your counting inventory:

Most companies’ working capital invested in inventory is about 20% - 40%. If you are closer to the 40% mark, it is time to develop an inventory reduction strategy in the supply chain. The aim is to discover your inventory sweet spot where you have the minimum available stock levels while not being overstocked to enhance your business’s development and profitability. There are three techniques for reducing inventory that may be helpful for you:

Inventory management software is capable of accepting inventory movement reports (transactions), maintaining an ongoing record of stock levels, and more. Thus, we suggest some tools for you to integrate with inventory management to increase inventory visibility and control in the supply chain or managing the warehouse.

👉 Read More:

A high-quality and efficient inventory management system is very necessary. When done correctly, it leads to better productivity, increased customer happiness, and increased profit. Thus, let’s put these best practices for inventory management into action right now! You've found this article so helpful? Let's forget to follow our Fanpage and website to get many interesting articles related to other management techniques in the warehouse!