More Helpful Content

The connections you make with your vendors may have a significant influence on your procurement function’s capacity to create value for your firm as well as your organization’s overall bottom line.

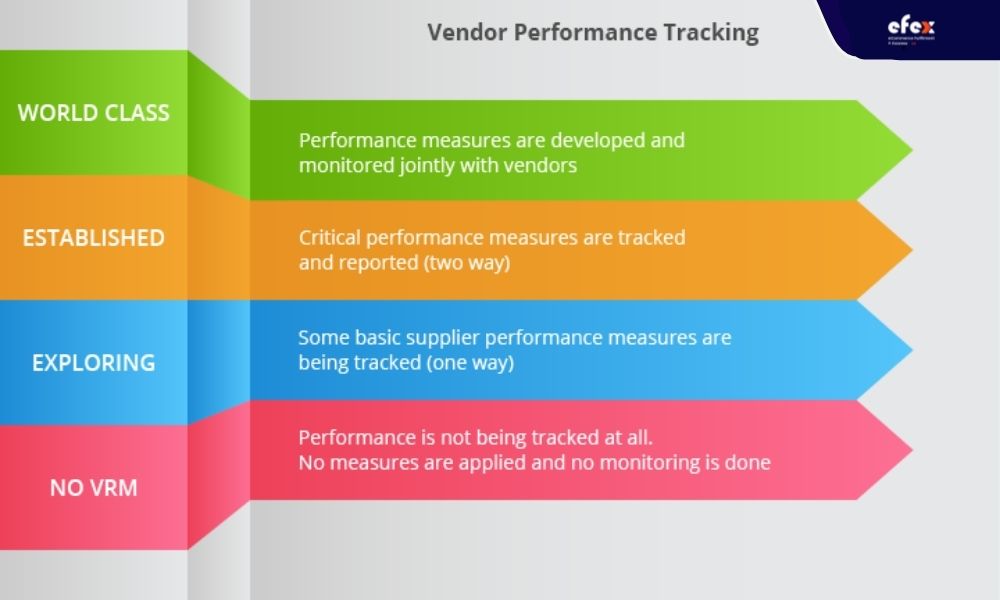

However, you cannot rely on every provider to execute their job on their own. You must keep track of the progress over time to ensure they are meeting their contractual responsibilities. Key performance indicators for vendor management will help you achieve that.

You can set a rich, data-driven approach to supplier management that is associated with high value, low risk, and strategic sourcing by developing, monitoring, and adjusting vendor management KPIs.

Cost reduction and adding value are two of the most essential ways in which procurement may enhance your company’s business operations. Both of these benefit greatly from ongoing development, which necessitates being aware of how well your procurement department is exploiting its supply chain and creating beneficial changes as appropriate.

You may hold your vendors accountable for their performance once you have established baseline requirements for them. You can also cooperate with them to ensure that they satisfy or surpass your expectations.

- See more: Order Management System: Definition, Process And Value

The ultimate aim is to guarantee that your business goals are addressed while also putting both the vendor and your business on a long-term, mutually beneficial path. Vendor KPIs provide the clarity required to identify gaps and provide help, allowing you to achieve your target.

The vendor scorecard makes it much easier to evaluate providers efficiently. When properly stated and well monitored, these scorecards allow you to express your objectives and assessment techniques to your vendors from the beginning. As a consequence, you obtain a solid understanding of a vendor, which are:

When you analyze each supplier and transmit your performance review to their representatives, having real evidence to back up your rating makes dialogue much more effective and helps move the focus away from perceived slights or unnecessary complaints and toward improvement.

- See more: Order management system for Ecommerce: Definition, Key Effect, Benefit

The vendor management KPIs that are most important to your business is not always the same as those that are most important to your competitors. Having said that, it is likely that the majority of your genuinely relevant metrics will be concentrated on critical aspects of vendor capacity, compliance, and performance.

Organizational success is measured by key performance indicators (KPIs). Supplier management KPIs ensure that value is received for money spent with suppliers and vendors while keeping a cost-cutting mindset in mind. You can analyze your firm's distribution system by using a variety of criteria, including supply chain management, relationship management, performance measurement, lifecycle management, and contract management. Here are the top 15 KPIs you should consider applying to your business.

As a business with compliance duties, you are accountable not only for your own needs but also for those of your suppliers. Adding an observation to vendor management can aid in spotting potential issues which can be addressed before unexpected costs or substantial fines arise. Key performance indicators may include the disputes to total invoices ratio, or the proportion of orders where the amount paid exceeded the price given against orders where both values are the same.

Another important key performance management is the defect rate, which is a strong measure of vendor quality. It is calculated by dividing the total number of orders by the number of faulty orders.

Another important purchase KPI is accuracy. Higher accuracy may lead to cheaper expenses. Therefore, it is critical to discover which providers are not meeting your expectations. KPIs include a percentage of the number of times an order was delivered and finished correctly to the total number of orders during a certain period.

👉 Read More: 15 Useful Tips To Improve Inventory Management

It is a supply chain key performance indicator that measures the time elapsed between the receipt of an order and its delivery date. Longer lead times may imply poor procurement performance over time.

The PO cycle lengths or purchase order cycle time calculates the entire ordering system, from the time an order is filed to the time it is delivered to a vendor.

Each organization’s cost per purchase order or invoice may seem different and fluctuate. The goal is not to save money, but to understand the components that go into the final cost and compare it over time and against other providers. It can assist in identifying areas for improvement. This might include determining whether to source from a lower-cost vendor or automating parts of the invoice process or purchase order.

Procurement ROI aids in measuring the total cost-effectiveness of a supply chain strategy and its associated expenses. The KPIs are calculated by dividing yearly cost savings by annual procurement expenses.

Calculate the product sent versus items requested, or the number of services completed versus that of services requested, to estimate your vendor’s capacity to respond to crises.

The compliance rate takes responsibility for keeping track of how frequently your vendors satisfy their contractual obligations. Pricing, delivery timeframes, and the quality of goods and services are all examples of metrics.

This KPI compares the prices your vendor charges for a product or service to those of rivals. You should be paying a reasonable market value for the product level of service you are receiving.

It determines the number of discounts your business has gotten as a result of early payments, group orders, goodwill gestures, and bulk orders (after vendor errors).

The KPI analyzes your supply quality by keeping track of how many unsuccessful objects or services you receive in comparison with the total number (typically per million). Categorizing faults by category can assist in driving improvement.

The order capacity KPI compares the number of times your vendor met the demand to the total number of orders to see whether they have the ability to satisfy your expanding demands.

It tracks and grades how successfully your vendors handle any complaints or difficulties your staff has with their products or services. You should also assess your staff’s attitude toward your vendor to determine whether you are a terrible client.

Examine the added value that partnering with a specific vendor brings to the normal service or goods that they offer. You may also use this statistic to encourage vendors to create cost-effective solutions to satisfy corporate objectives.

Credentials and other documentation demonstrating that your vendors are financially secure, diversified, and practice both ethical and sustainable sourcing should be provided by your suppliers. Furthermore, they should have the infrastructure required to safeguard any sensitive customer data.

In your supplier relationship, issues will arise that will impact your vendor's ability to work within stated bounds. To prevent threatening a potentially good vendor relationship, you must think about and track these conditions.

You must have access to information about your vendor connections. Without this, you are forced to “trust” your provider to fulfill your contract, which is just too dangerous for any business. If you do not want to measure the wrong data and collect too many data points, the trick is to understand how to evaluate your KPIs and score them in a way that truly represents the effectiveness of your vendors.

👉 Read More: 15 Best Practices For Inventory Management

The best approach to do this is to concentrate and analyze your contracts. This is where you will discover the specifications for your vendor partnerships. You will want to compare those guardrails to your company’s goals and demands. This might help you uncover holes in previous vendor partnerships that you can review during your renewal or next contract negotiation.

You should utilize these frameworks to develop a contract for prospective vendors that meets your organization’s particular needs. Once you have determined which metrics you can and should follow, you will need to collect vendor information data in a system that enables you to swiftly assess supplier performance. It is often a spreadsheet in firms that do not have a vendor management system.

However, these may be extremely problematic and damaging to your company.

It is critical to review your vendor’s performance management frequently. It assures that you receive what you paid for and lowers the risk for your firm. Moreover, you may use strong vendor connections to boost your company's competitiveness. If you do not utilize a vendor management system, or track vendor performance by using spreadsheets and a paper-based review system, the process can be incredibly time-consuming.

👉 Read More: 15 Techniques Of Inventory Control You Need to Know

So, the solution is to use automation to streamline your vendor review process. Then you can accomplish it quickly and cheaply by employing low-code. You may quickly construct the bespoke applications you need to handle your vendors with little code. You may create a self-service vendor portal and vendor management system with no coding, which allows you to easily track vendor performance.

Vendors can use the vendor site to update their information, issue invoices, and offer comments or correspondence. In a vendor management system, you may track data alongside your vendor KPIs.

👉 Read More: 20 Important KPIs For Inventory You Need to Notice

Finally, you will have real-time data about your vendors that you can utilize to improve the efficiency and strategy of your procurement process. Thus, although you will undoubtedly save money, you will also gain the insights you need to keep your firm adaptable while decreasing risk.

A strong program to enhance the vendor management KPIs results in more than just cost savings. You can anticipate greater levels of client satisfaction if you can rapidly identify the fundamental causes of problems and remedy them.